1, Compression injection molding

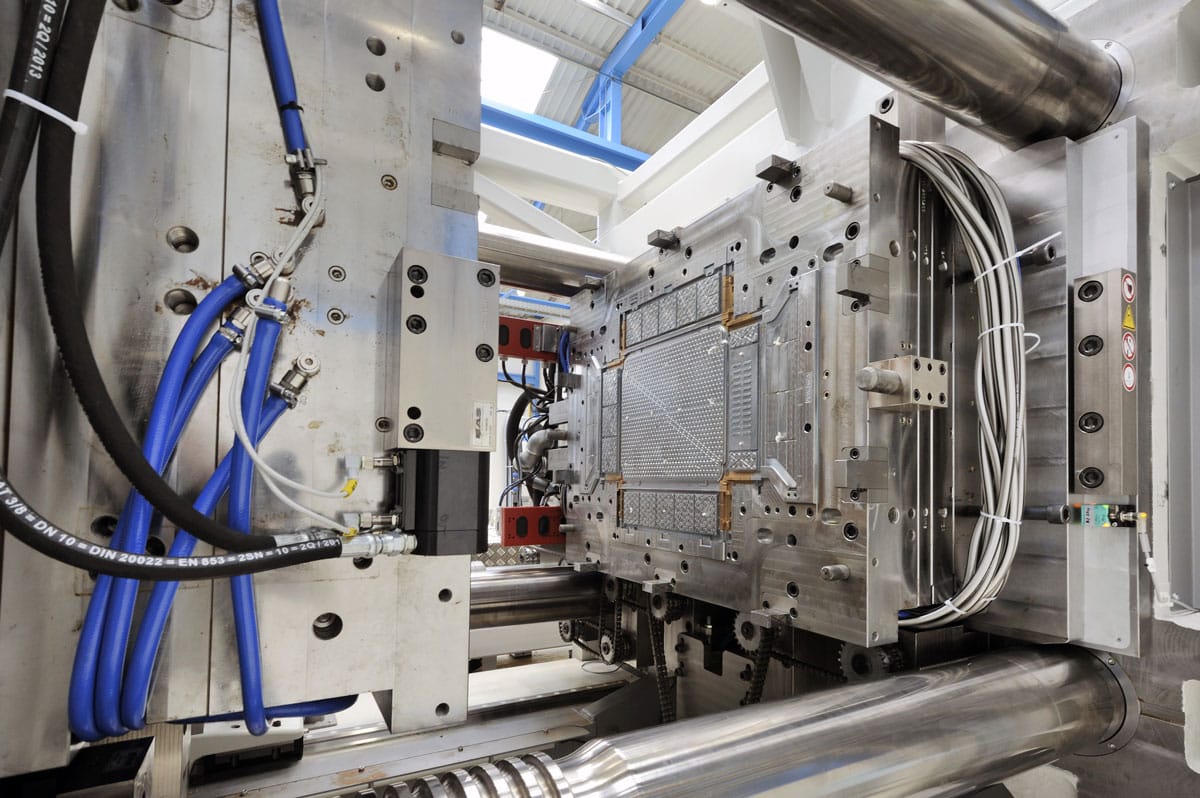

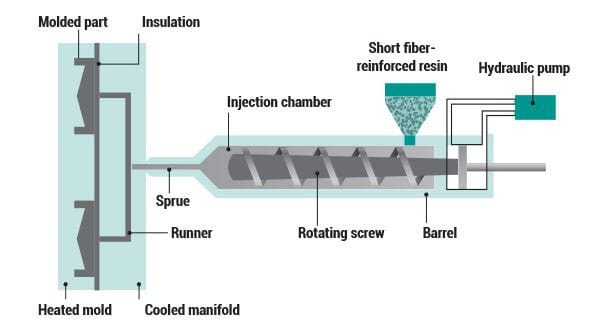

Compression injection molding is a more traditional injection molding method

Principle:

First, the molten material is injected into the mold cavity. When the molten material enters the mold lung, the mold is slightly opened under the pressure of the pressure knife. After the molten material fills the cavity, the mold is locked with high pressure to produce the desired product. The second step is press molding. Because the molten material enters the cavity with the mold already slightly open, the required mold force is relatively small.

During molding, the screw no longer injects material into the mold cavity, but relies on high pressure to lock the mold, thereby pressing the force Lf on the plastic to form the product. As a result, the product orientation is small and the internal stress is low. This method is particularly suitable for molding small products with high transparency requirements.

Advantage:

It can increase the flow length ratio of injection molded parts; use smaller clamping force and injection pressure; reduce internal stress in the material; and improve processing productivity.

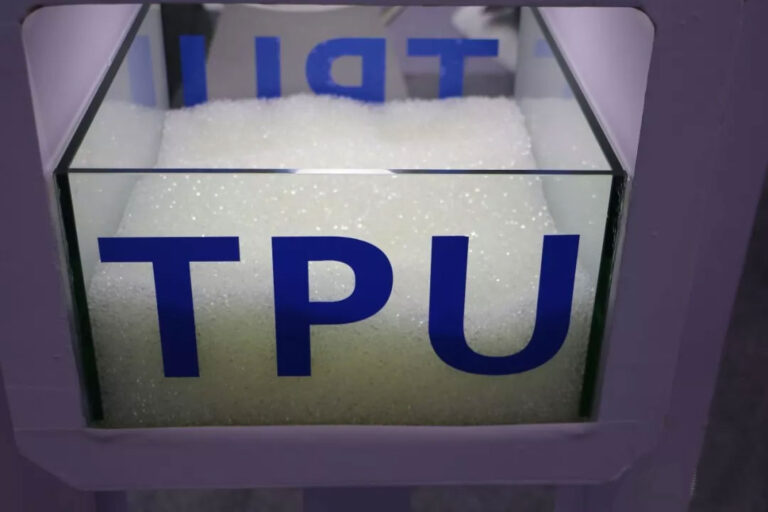

Injection compression molding is suitable for products made of various thermoplastic engineering plastics; such as large-sized curved parts, thin-walled, miniaturized parts, optical lenses, and parts with good impact resistance requirements;

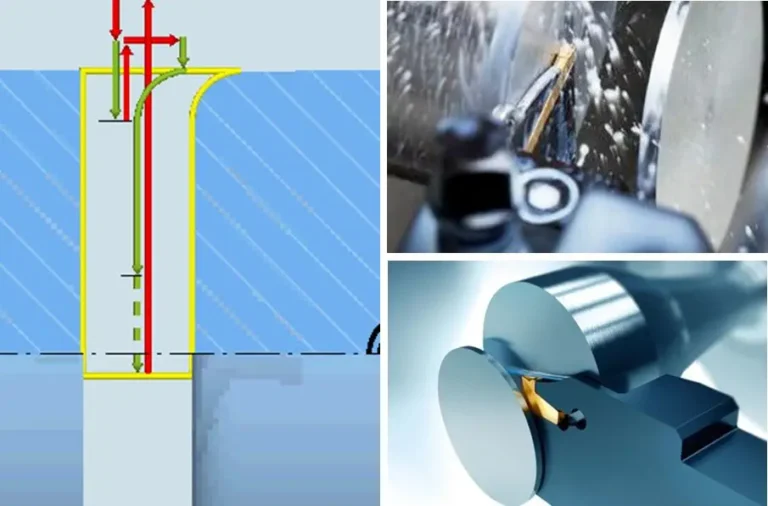

2, Exhaust Injection Molding

Principle:

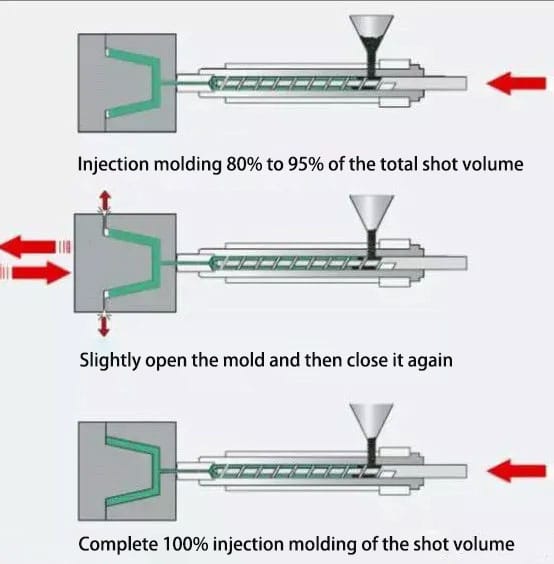

When the injection volume reaches about 80%-95%, the injection is paused; the mold is opened about 0.1-0.2mm to allow the volatile gas to be discharged; the mold is closed again and the remaining injection volume is injected.

Advantage:

Gas-assisted injection molding has lower injection pressures for parts, so equipment with lower clamping forces can be selected to mold larger parts.

3, Low pressure injection molding

Principle:

The compression injection molding process is a packaging process that uses very low injection pressure to inject hot-melt material into the mold and quickly solidify it. The hot-melt material’s excellent sealing and excellent physical and chemical properties achieve insulation, heat resistance, impact resistance, vibration reduction, moisture resistance, waterproofness, dust resistance, and chemical corrosion resistance, providing good protection for electronic components.

Advantage:

The equipment cost of low-pressure injection molding process is low;

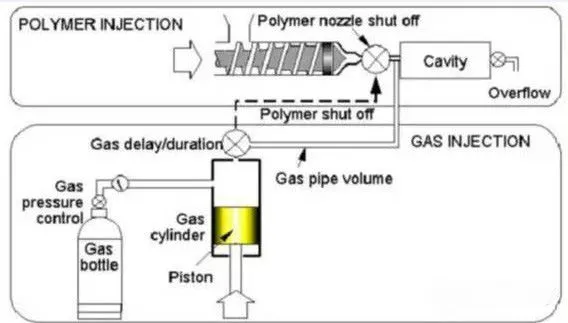

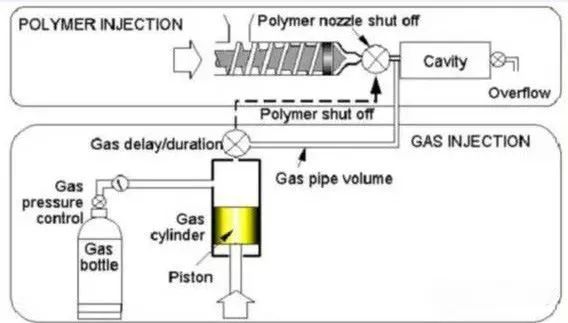

4, Gas-assisted injection molding

Injection stage (partial) – filling stage (N2) – gas pressure holding stage (cooling pressure remains unchanged) – decompression stage – demoulding stage

Advantage:

Gas-assisted injection molding technology has many incomparable advantages. It not only reduces the manufacturing cost of plastic products, but also improves some of their properties. Under the condition that the parts can meet the same use requirements, the use of gas-assisted injection molding can greatly save plastic raw materials, and the saving rate can be as high as 50%. On the one hand, the reduction in the amount of plastic raw materials brings about a reduction in the time of each link in the entire molding cycle.

5, Water-assisted injection molding

Water-assisted injection molding technology is an advanced injection molding process that injects part of the melt into the mold cavity, then injects high-pressure water into the melt through equipment to finally shape the workpiece.

Advantage:

Due to the incompressibility of water, the water front forms a solid interface, squeezing the inner wall of the product into a cavity. The water front also acts as a rapid cooling agent. Therefore, water-assisted cooling offers many advantages over gas-assisted cooling. Research and application have shown that water-assisted cooling can produce thinner and more uniform cavity walls, and the inner surface of the flow channel is very smooth. Especially for thick-walled workpieces, water-assisted cooling can significantly reduce cooling time compared to gas-assisted cooling.

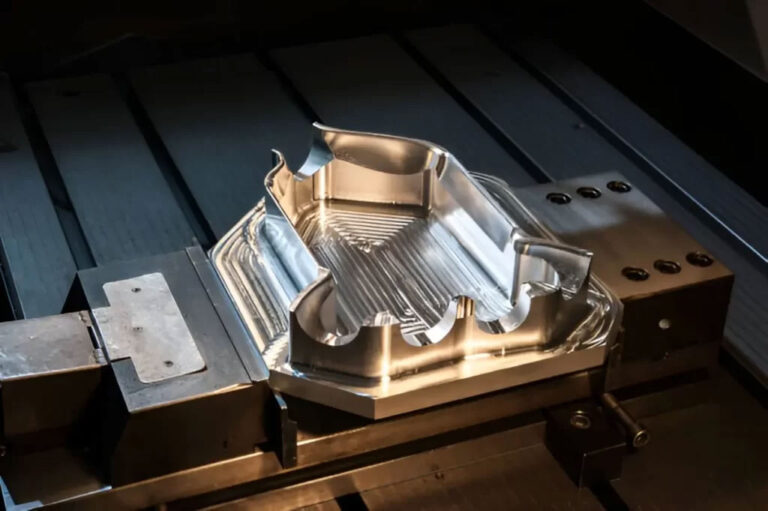

6, High-gloss injection molding

The basic process of high-gloss injection molding is to use high-temperature, high-pressure steam to quickly heat the mold surface before injection molding, so that the mold cavity surface temperature reaches above the glass transition temperature (Tg) of the resin plastic. Then, the plasticized plastic melt is injected into the closed mold cavity. During the injection phase, the mold temperature is kept constant by the high-temperature, high-pressure steam. When the injection is completed, the air supply is stopped and the air pressure in the air pipe is blown out to clear the water vapor in the pipe. Then, cooling water is introduced to quickly reduce the mold temperature until it cools down and the mold is opened to remove the product.

Advantage:

Compared with ordinary injection molding, it can effectively eliminate defects such as weld lines, ripples, silver lines, floating fibers, etc. on the product surface, improve product quality and strength, and completely solve the surface marks of the product.