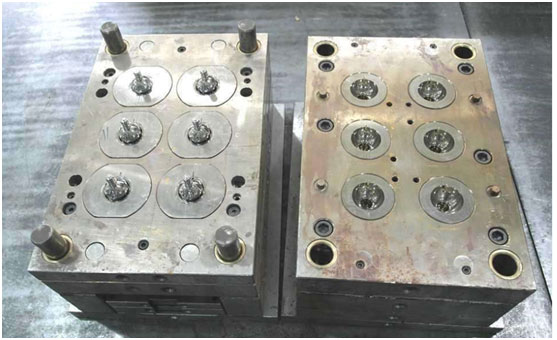

The service life of the silicone mold during mold remodeling directly affects our costs. Although it is important to choose high-quality mold silicone raw materials and use appropriate mold opening methods when making silicone molds, it is equally important to maintain the silicone mold in the later stage, which can prevent it from being damaged so easily. So how to properly maintain the silicone mold?

1, During the production stage, make sure to remove as many bubbles as possible from the mixture, as too many bubbles will not only affect the appearance but also its durability.

2, Remember that acidic and alkaline materials can damage or inhibit silicone molds. For example, it is best not to pour polyurethane into a condensation-type silicone mold without a release agent. Mixtures containing sulfur, amines, tin, etc. will affect the curing of addition-type silicone.

3, Try not to tear or cut the shape of the silicone mold. If the overall integrity of the silicone mold is damaged, it is easy to tear along the cracks, which will accelerate further damage to the mold.

4, Use lubricants and release agents, especially when casting materials with corrosive components, which will help extend the life of the mold.

5, Don’t forget to clean your mold after use. When cleaning, a soft brush and soapy water are enough. Wipe the mold dry after cleaning.

6, Try to store and use the mold only at room temperature. Using the silicone mold at high temperature will accelerate aging.

7, If the mold is a non-standard shape, it can be reinforced with an external mold. It is best to store it after assembly, and do not take out the model inside to prevent the silicone mold from deforming.

8, Silicone molds are best stored in separate boxes, away from sunlight, moisture and other adverse environments.

Remember these simple maintenance operations, your silicone mold can greatly extend its service life!