Intro

Sheet metal processing, as an efficient and precise metal processing technology, has been widely used in various fields of manufacturing.

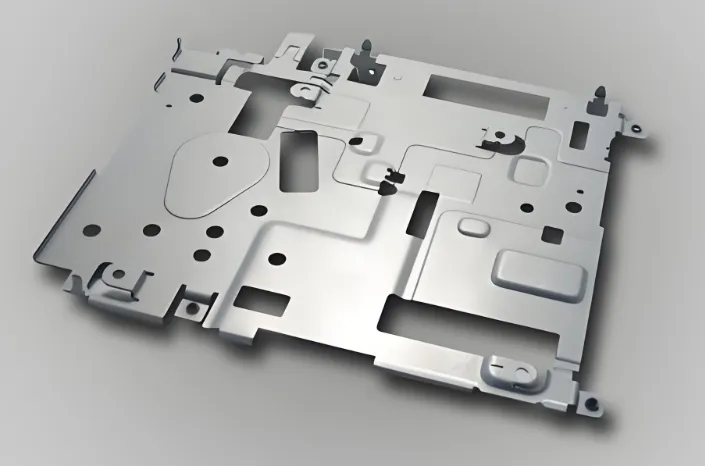

It mainly processes metal sheets through molds to make them plastically deform or separate, thereby obtaining parts of the required shape and size.

Sheet metal processing

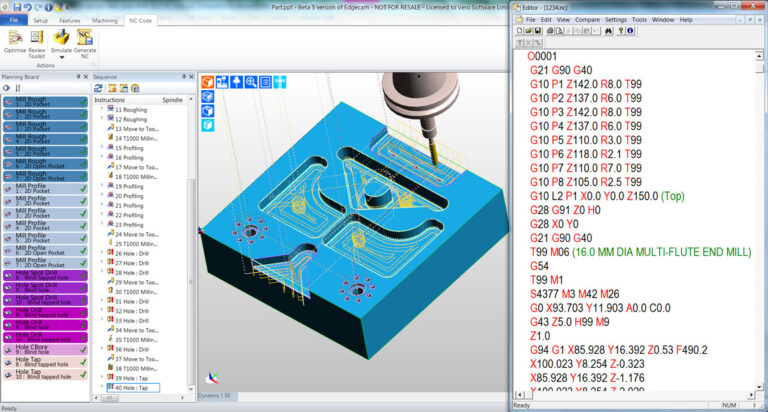

Sheet metal processing technology mainly includes the following steps:

① Cut the metal sheet into the required shape through a shearing machine;

② Use a punching machine to punch out the required holes on the sheet;

③ Use a bending machine to bend the plate along a specific bending line;

④ There are also processes such as deep drawing and die casting, which enable the sheet to be formed into more complex shapes;

⑤ Finally, through welding process, metal parts of different shapes are connected to form a complete product.

After processing is completed, the sheet metal products can also be subjected to surface treatment, such as spraying, plating, etc., to improve the aesthetics and durability of the prototype and product.

Application of sheet metal processing

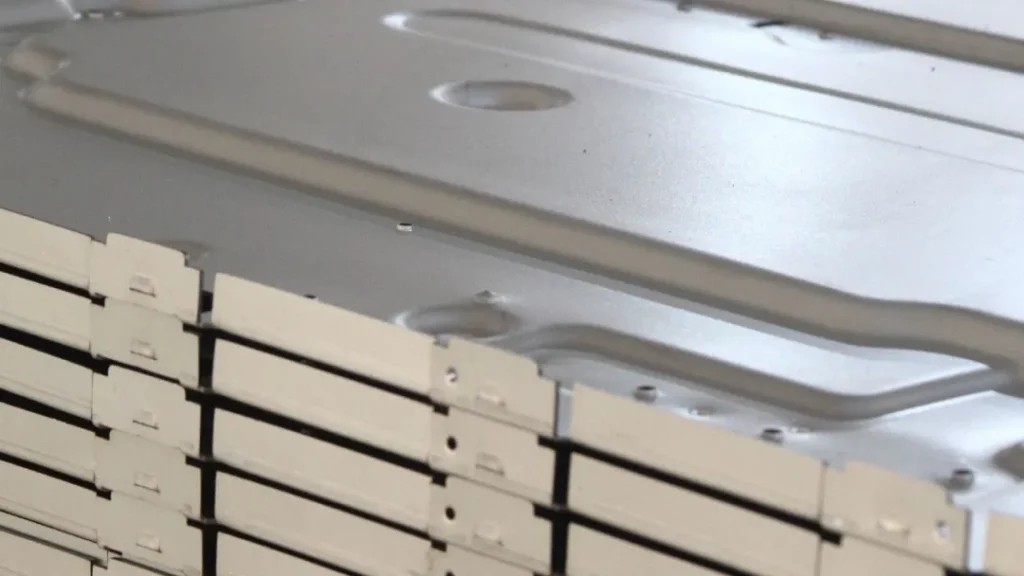

Sheet metal processing technology has a wide range of applications, involving multiple industries and parts production.

①In the automotive industry

Sheet metal processing is a key technology in the manufacture of vehicle bodies and components. Through precise machining processes, high-strength, high-rigidity, yet lightweight automotive structural components can be manufactured, improving vehicle safety and performance.

In addition, sheet metal processing parts also play an important role in automotive electronic systems, such as battery housings and connectors.

② Electronic equipment and home appliance industry

Sheet metal processing also plays an important role in the field of electronic equipment and home appliances. For example, computer cases, TV housings, air conditioner radiators and other components all need to be manufactured through sheet metal processing.

These components are not only required to have good appearance and texture, but also to meet certain strength and heat dissipation performance.

Sheet metal processing can accurately produce products that meet the required shapes and sizes, and through surface treatment processes, improve the appearance and durability of the products.

③Construction , aerospace, railway transportation and other industries

In the construction industry, components such as doors, windows, and balcony railings are often manufactured using sheet metal processing;

In the aerospace field, aircraft fuselages, wings, and structural components of spacecraft such as rockets and satellites also need to be manufactured with high precision through sheet metal processing;

In the railway transportation industry, the bodies, doors and other components of railway vehicles also rely on sheet metal processing technology.

Conlusion

In general, sheet metal processing occupies an important position in the manufacturing industry due to its advantages such as high efficiency, precision and good repeatability.

With the continuous advancement of science and technology and the continuous development of the market, sheet metal processing technology will continue to play an important role in more fields and inject new vitality into the development of the manufacturing industry.