Introduction

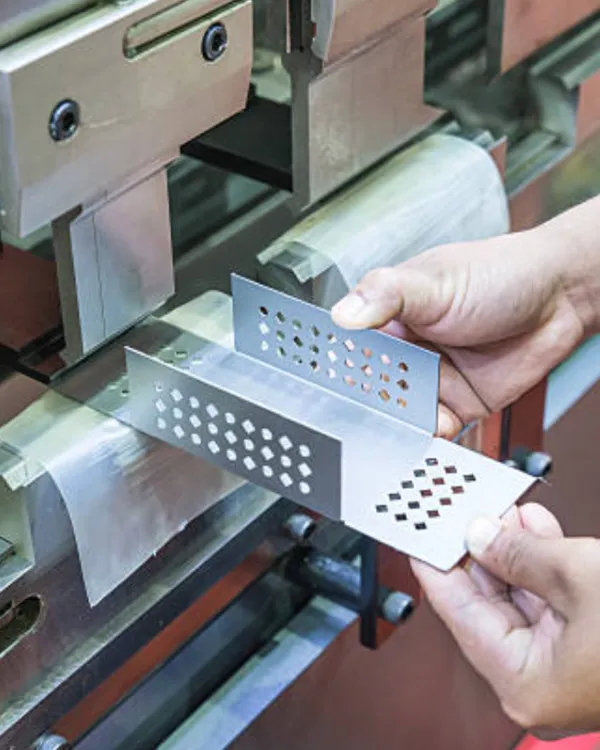

Sheet metal bending is one of the basic processes in sheet metal manufacturing and is also a basic operation for manufacturing sheet metal stampings. Sheet metal bending means deforming the workpiece, applying force to the workpiece with the help of a sheet metal bending machine to form it into a certain desired geometric shape. The process is not as simple as it seems, there are some dimensions and rules that need to be met, for example, the material of the product needs to be checked, the K factor needs to be calculated, the shape of the metal processing, and so on.

As the demand for customized products increases, the range of applications for sheet metal is also expanding. Sheet metal bending requires multiple processes and utilizes a variety of techniques to give the product its original shape. A single machine can utilize different bending methods to do the same job. This article details all the necessary bending methods and processes.

Common methods of sheet metal bending

All sheet metal parts have the same goal, which is to bend the metal sheet to achieve a certain product shape. But the methods differ in the execution of the operation. These different types of bending are done with the help of machines. Different bending metal sheets differ in the bending angle and bending radius, with the aim of achieving a standard technology, which not only guarantees accuracy but also gives the workpiece a better aesthetic. The main types of sheet metal bending processes are:

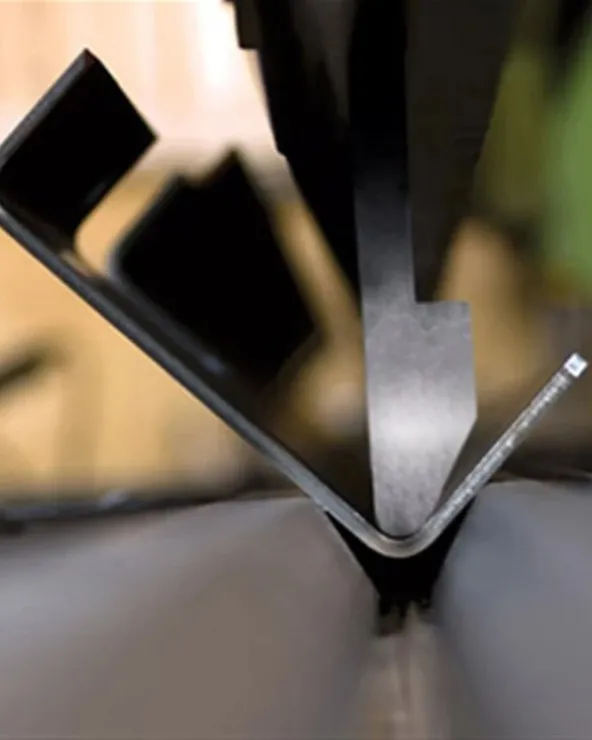

1.V-shaped bending

V-bend is the most common sheet metal bending process. It involves the use of machine tools such as dies and punches. The die used in this bending process is a V-shaped die, and the punch is also designed with a V-shaped angle. The punch presses the metal sheet into the V-shaped die, and this is how the V-shaped bend of the metal sheet is obtained.

2.Roller bending

This sheet bending technology involves bending the sheet into a curved form. This technology utilizes the roller bending sheet standard and involves the use of three rollers, a hydraulic hold-down system, and a brake. The distance between the three rollers allows the manufacturer to bend the sheet into a curve.

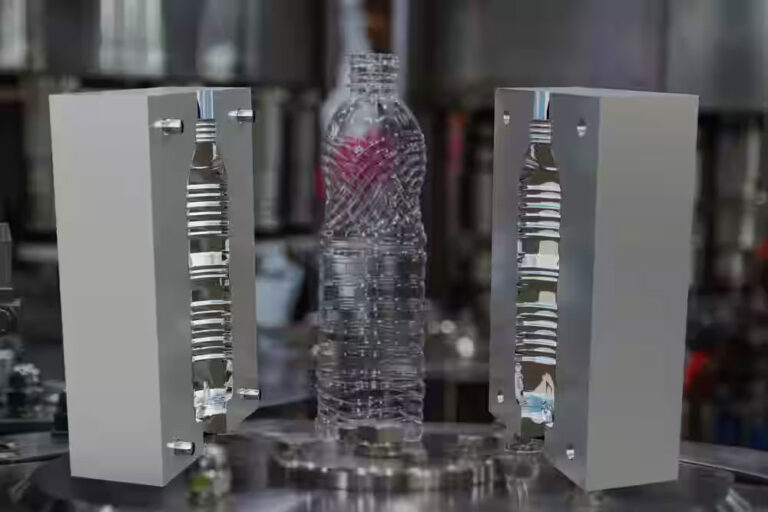

3.U-bend

The U-bend is completely similar to the V-bend method. This method utilizes a U-shaped punch and a U-shaped die. The only difference between the V-bend and the U-bend is that the resulting sheet is a U-shape instead of a V-shape.

4.Rotational bending

The rotary bending method is used anywhere a bend greater than 90 degrees is required. It can also be considered similar to a V-bend, but the sheet metal bending machines used in this method will not scratch the surface of the sheet, resulting in a more uniform and aesthetically pleasing output.

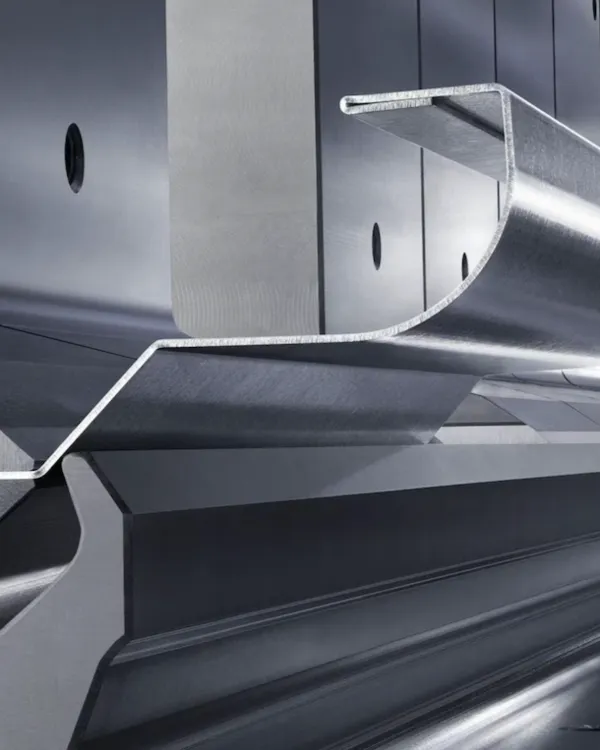

5.Folding

This hemming technique helps manufacturers bend the edge without damaging it. The sheet hemming method is most often used on sheet sections that are shorter than the remaining metal part. It helps eliminate the sharpness of the corners and adds to the aesthetic appearance of the product.

6.Wipe the bend

This bending method uses a wiping die. The metal sheet is carefully placed inside the wiping die and a pressure pad applies pressure to the sheet. Then, a punch is used to make the desired bend in the sheet. The amount of relaxation between the wiping die and the punch plays an important role in achieving good results.

Sheet Metal Bending Applicable Materials

When bending elastic-plastic materials on a press brake, it may also damage your machine. Therefore, you must be particularly careful when you decide to perform sheet bending in your manufacturing process.

Carbon Steel: Carbon steel is one of the most flexible and strongest materials used in plate processing. Since this material is recyclable, it will also help reduce the carbon footprint.

Aluminum: Aluminum is primarily used in lightweight applications. Special care must be taken when bending aluminum to avoid collapsing or cracking the corners of the material.

Stainless steel: When the final product needs to be durable and have better metal strength, stainless steel is the first thing that comes to mind. Stainless steel also requires the use of high-powered plate bending machines to form the product.

Titanium Alloy: Titanium is a corrosion-resistant material and a high-strength material, making it ideal for sheet metal bending technology. If your product is medical or sports equipment, then the most popular material on your list should be titanium.

Copper: The most costly corrosion resistant material, but also the cheapest. High precision sheet metal bending is made from copper. Copper is a tested material that is widely used by many metal bending industries in a variety of applications.

These are the best materials to use in various sheet metal bending. Carbon steel is the most commonly used material among the above mentioned ones. There are many more metals that can help in the bending process. But before you finalize the material, make sure you do a good research.

Common problems in sheet metal bending

1.Cracks appear at the bending angle

The two main causes of cracks in drawn parts are poor metal flexibility and small bend radii. To avoid these defects, use softer metal or increase its ductility by heating it and then cooling it slowly.

2.Unstable bending angle

The main causes of these defects are irregular compression buckling caused by insufficient material pressure and irregular bending pressure. Asymmetric punch and die radii can also cause this problem. To solve this problem, the jacking force should be increased to balance the gaps in the punch and die radii.

3.Hole deformation

The position of the hole will be deformed during the bending process due to the friction between the die surface and the outer surface.

This defect can be solved by increasing the pressure of the ejector plate or adding a hard point on the plate to increase the friction between the above surfaces so that they do not slide.

4.The bottom of the concave piece is not flat

Such defects are usually caused by using an ejector, insufficient force, or uneven material. Therefore, make sure the ejector is set to the correct force unit, or remove it altogether, and ensure that the material is evenly flat before starting the bending process.

5.Non-parallel bending to the middle of the hole

This defect is caused by the bend height being less than the minimum bend height limit, causing the curve to expand and deform. These types of defects can be resolved by simply increasing the height of the bend or material.

Sheet Metal Bending Processing Techniques

1.Use the bending allowance

Bend allowance is a property of how well metal can be bent. We recommend that you perform a bend allowance calculation to determine the sheet length required to make a bend of a specific angle and radius. Considering bend allowance and bending force during manufacturing will help you achieve a cleaner product outcome. It will also help you achieve an accurate, flat manufacturing model.

2.Use heating for thick/heavy bends

Some metals can break or crack when bent with force. These types of metals require heat rather than force to bend the sheet. Hot forming and annealing are two terms for hot bending. Annealing helps soften the metal – making it more ductile. Hot bending, on the other hand, simply uses heat until the metal turns red, then applies force to bend it. These techniques greatly reduce the risk of the metal braking and cracking.

3.Avoid sharp inner corners

Sharp internal angle bends mean greater internal stress. Even though the metal is ductile and malleable, it may eventually break. This problem can be largely avoided if you consider the radius of your bending tool. You should slowly work back and forth between the bend lines until you bend the sheet to the desired angle.

Attention should be paid to the inner bend radius, which must be equal to the formed sheet thickness. For example, if you are bending a sheet with a thickness of 3 mm, the inner bend radius should also be 3 mm. The same is true for the bend angle, which means it cannot be greater than the overall thickness of the metal sheet. These are some of the tips that you need to consider when bending sheet metal. Making sure to check each and every one of the tips above will help you get your product with greater efficiency.

Summary

Sheet metal bending is an important sheet metal process because it can draw a variety of part geometries without tools, with fast lead times, repeatability and high automation. It also allows products to be manufactured from a single piece of metal, utilizing plastic deformation rather than joining multiple parts together by welding or riveting, thereby reducing costs, increasing strength and simplifying assembly.