Vacuum Casting

What Is Vacuum Casting?

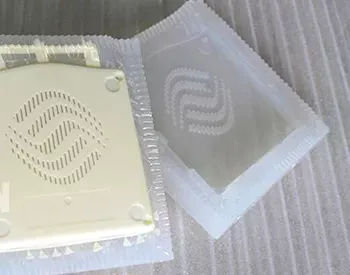

vacuum casting is a technology for making replicas, also known as Vacuum injection molding. Generally, a prototype is first produced using methods such as 3D printing and CNC processing. Then, a silicone mold or rubber mold (currently mainly silicone) is made from the prototype. Then, liquid resin is injected into the mold under vacuum and hardened.

Applications Of Vacuum Casting

- Plastic prototype: Its raw material is plastic, mainly for prototypes of some plastic products, such as televisions, monitors, telephones, etc. For example, the most common photosensitive resin in 3D prototype proofing belongs to the plastic prototype category.

- Silicone laminated prototype: Its raw material is silicone, and it is mainly used to display the design appearance of products, such as cars, mobile phones, toys, handicrafts, daily necessities, etc.

Pros and Cons of vacuum casting:

Pros | Cons |

|---|---|

Processing Steps

Master Pattern Preparation

Prepare the master pattern via 3D printing (SLA/DLP), CNC machining, or existing physical parts, ensuring surface smoothness (polishing/sandblasting if needed) and ≥1° draft angle for damage-free demolding.

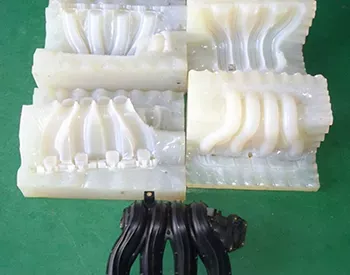

Mold Making

Secure the master pattern in a mold frame with reserved pouring vents/air channels, vacuum-mix liquid silicone (e.g. RTV-2) with curing agent (-0.1MPa), pour into the frame for curing (4-8h at RT or 2-4h at 60°C), then split the mold along parting lines to extract the master and create the cavity.

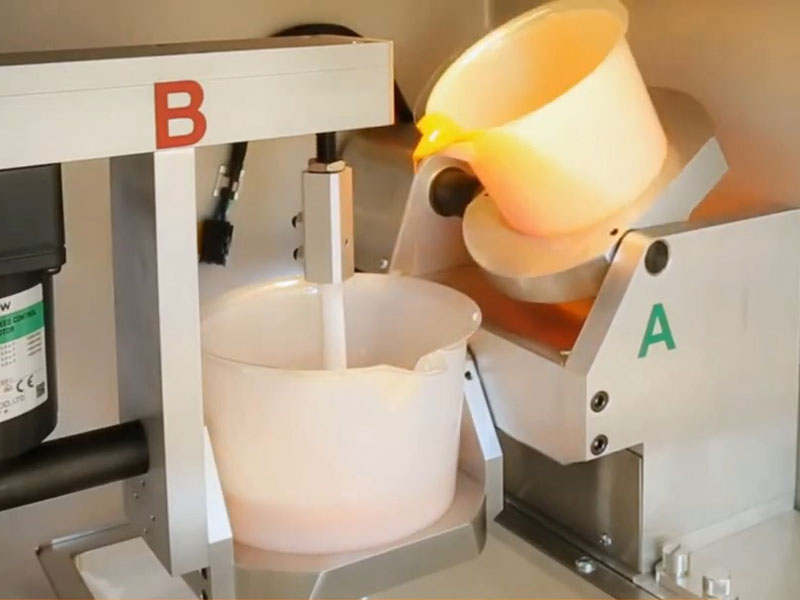

Controlled Vacuum Infusion

Prepare polyurethane (PU) or epoxy resin materials by vacuum degassing after mixing, inject into the silicone mold under vacuum to prevent bubbles, seal the gate, then cure at room temperature or with heating (typically 1-4 hours depending on material).

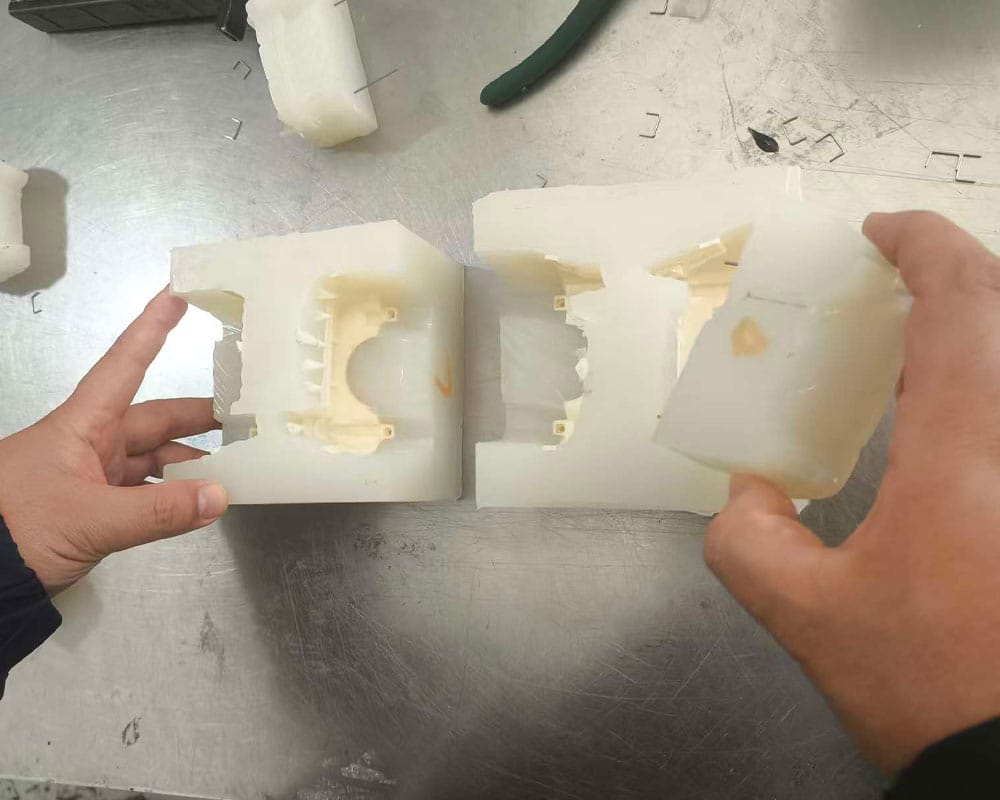

Demolding & Post-Processing

Carefully separate the silicone mold to extract replicas, trim parting-line flashes/gates, then apply surface treatments (painting/plating/polishing) as specified.

Materials For Vacuum Casting

| Material | Plastic: |

| • ABS – (White / Beige / Black / Clear / Customize color) | |

| • PC / Polycarbonate -(Clear / Translucent / White / Black / Customize color) | |

| • ABS+PC – (White / Clear / Black / Customize color) | |

| • PMMA / Acrylic – (Clear / Translucent / White / Black / Customize color) | |

| • PA / Nylon – (White / Black / Clear / Customize color / +30%GF) | |

| • PP / Polypropylene – (White / Black / Gray / Translucent / Customize color /+20% GF) | |

| • POM / Polyformaldehyde / Delrin – (White / Black / Customize color) | |

| • PVC / Polyvinyl chloride – (Beige / White / Gray / Clear / Customize color ) | |

| • Resin – (White / Black / Customize color) | |

| • Rubber – (Black / White / Clear / Customize color) | |

| • Silicone – (Clear / White / Black / Customize color) | |

| • TPU – (Clear / White / Black / Customize color) | |

| • TPE – (Clear / Translucent / White / Black) | |

| • PU – (Black / Coffee) ,etc. |

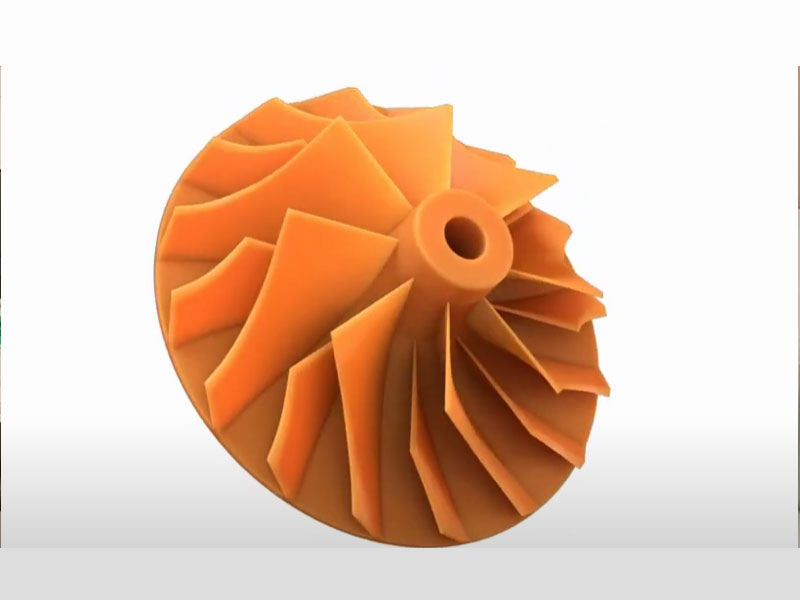

Case Presentation

FAQ

Expert Views From Gaofeng