Surface Treatment

Surface treatment

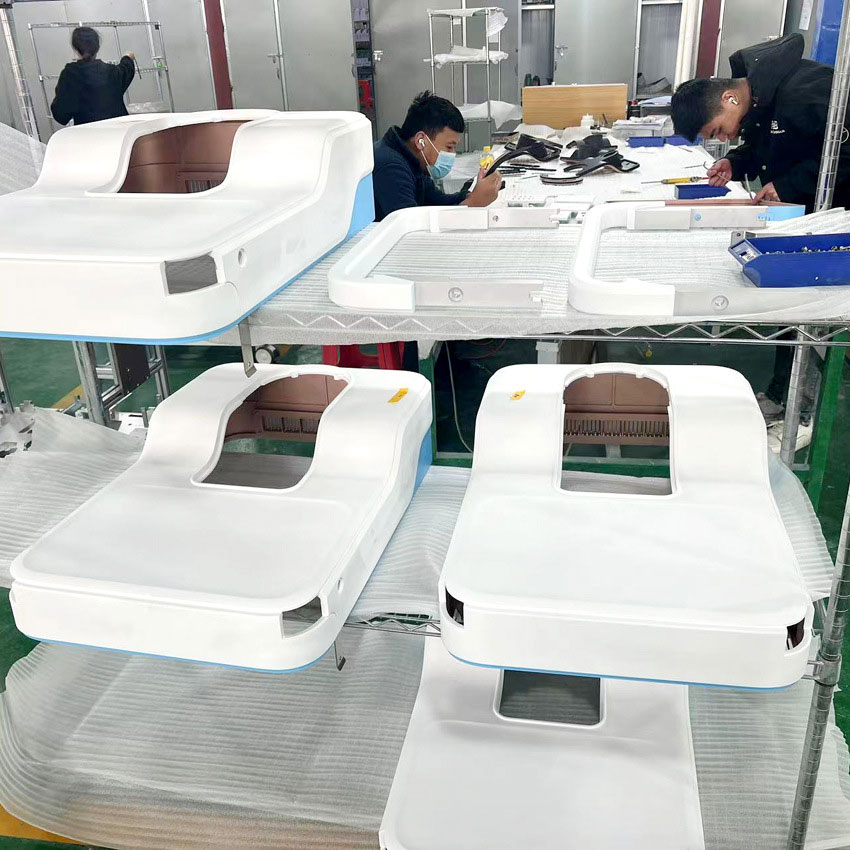

Whether it is CNC machined or 3D printed parts, to gain an accurate appearance of your final products, they must undergo a rigorous post finishing process before a product can be truly brought to life.

Spray Painting

To spray the processed and polished prototype with color according to the customer’s requirements.

Polishing

The surface of the newly machined prototype may have knife marks and burrs, which need to be polished smooth with sandpaper.

Common Surface Treatment Processes

Gaofeng provides high-quality surface treatment services for all products, and we have some highly skilled technical experts in surface treatment. If you wish to provide a perfect appearance for prototypes and other manufactured parts, please contact our customer service team.

Silkscreen printing

To print words or patterns on the flat surface of the processed and polished prototype.

Sandblasting

Roughening the surface by using the impact of high-speed sand flow.

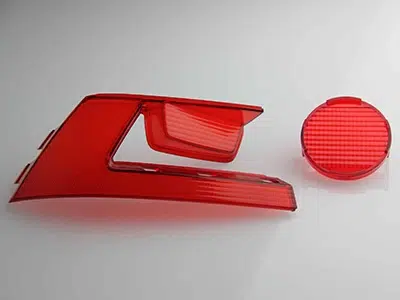

Dyeing

Besides spraying, dyeing is another option for coloring plastic prototypes.

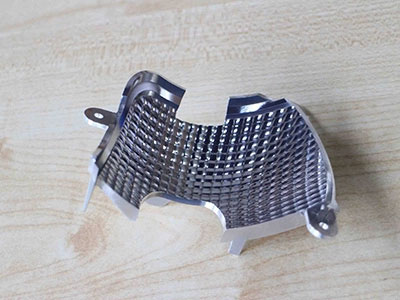

Electroplating

Plating a thin layer of other metals or alloys on the surface of materials.

Special Post Finishing

Gaofeng is capable of providing common post finishing, including hand-finishing, sanding, blasting, polishing, painting, and printing. We also offer a wide array of specialty surface finishing, including laser etching, anodizing, powder coating, metal plating, vacuum metalizing, chromate, chemical finishing, passivation, heat treatments, etc.

We can also provide

We can also provide:

Anodizing

Powder Coat

Eletrophoresis

Sandblasted & Bead blasted

Heat treatment

Chrome plating

Hard oxidation

Wire drawing

Water Transfer etc.

Prototype surface treatment process core comparison list

| Process Type | Main applicable materials | Typical application scenarios | Core Advantages | Main limitations | Cost estimate (relative value) | Durability (1-5 points) | Aesthetics (1-5 points) |

|---|---|---|---|---|---|---|---|

| fuel injection | Plastic (ABS, PC, etc.) | Appearance prototypes, consumer electronics housings | Rich colors, can cover substrate defects | Poor scratch resistance and easy to wear | Low | 3 | 4 |

| plating | Metal, plastic (ABS) | Decorative parts, hardware, buttons | High gloss, wear-resistant and corrosion-resistant | Complex process, high cost, and great environmental pressure | high | 5 | 5 |

| Oxidation | aluminum alloy | Chassis, radiators, high-end appearance parts | Corrosion resistant, high hardness, colorable | Aluminum only, limited color options | middle | 5 | 4 |

| Laser Engraving | Metal and plastic painted surfaces | Key characters, logos, and marks | High precision, permanent marking, contactless processing | Can only process shallow layers and has requirements for base color | Medium to low | 4 | 3 (Functionality-oriented) |

How to choose the Right surface treatment process?

For prototype production, we most commonly recommend and utilize oil spraying and oxidation, as they strike a good balance between cost, effectiveness, and applicability. For clients seeking the ultimate in metallic finish and with ample budget, we will carefully evaluate and recommend electroplating. Laser engraving is the perfect option for adding functional logos. Gaofeng, with our extensive experience in surface treatment, can provide you with professional process selection and quality control to ensure optimal prototype verification and display results.

When choosing a prototype surface treatment, please remember:

Paint spraying is the most cost-effective decorative option with incomparable colors, but it is relatively delicate.

Electroplating can provide the best metal texture and protective performance , but it is expensive and has high environmental protection requirements.

Oxidation is a perfect combination of function and decoration of aluminum alloy , which is strong and durable.

Laser engraving is used for precise, permanent marking and is the finishing touch to functionality.

The best way is to fully communicate your needs, budget and subsequent mass production plan with your prototype supplier (such as Gaofeng). They can provide the most practical process suggestions and solutions.