Intro

Many people do not quite understand the differences between prototypes and molds. Especially those who have no experience in this industry are more likely to be confused and cannot tell them apart, or even feel confused.

Now we will introduce to you the concepts and differences between prototypes and molds.

Prototype

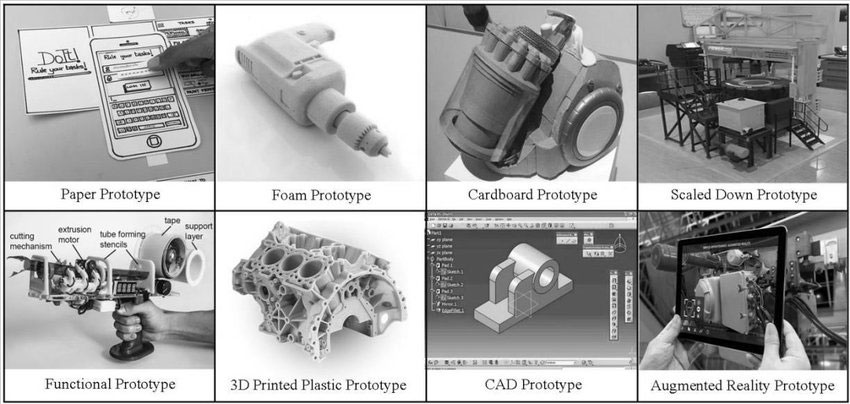

Let’s talk about the prototype first. The prototype can also be called a sample, a sample, or a model. In some places, it is also called the “first prototype”.

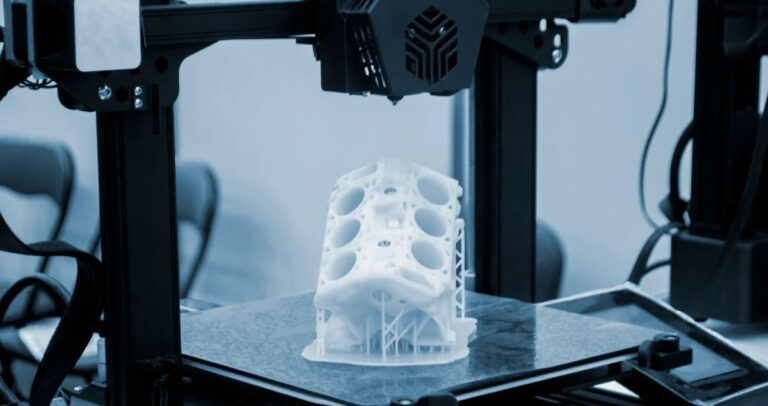

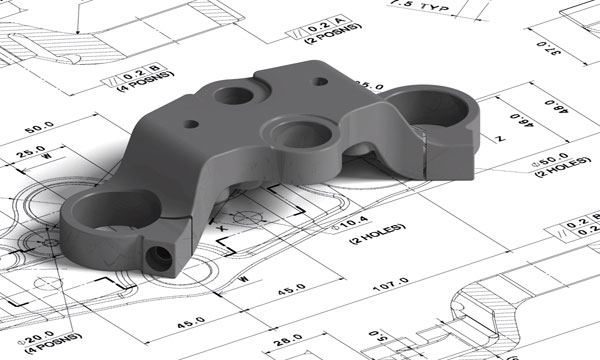

Prototype is the first step to verify the feasibility of a product. It is the most direct and effective way to find out the defects, deficiencies and drawbacks of the designed product, so as to make targeted improvements to the defects until no deficiencies can be found in individual prototype models.

Usually, a small batch trial production is required to find out the deficiencies in the batch and make improvements.

Generally speaking, a product that has just been developed or designed needs to be made into a prototype. The designed product is usually not perfect or even unusable. If it is directly produced and there are defects, it will all be scrapped, which greatly wastes manpower, material resources and time.

Prototypes are generally samples of a small number, with a short production cycle and little loss of manpower and material resources. They can quickly identify deficiencies in product design and make improvements, providing sufficient basis for product finalization and mass production.

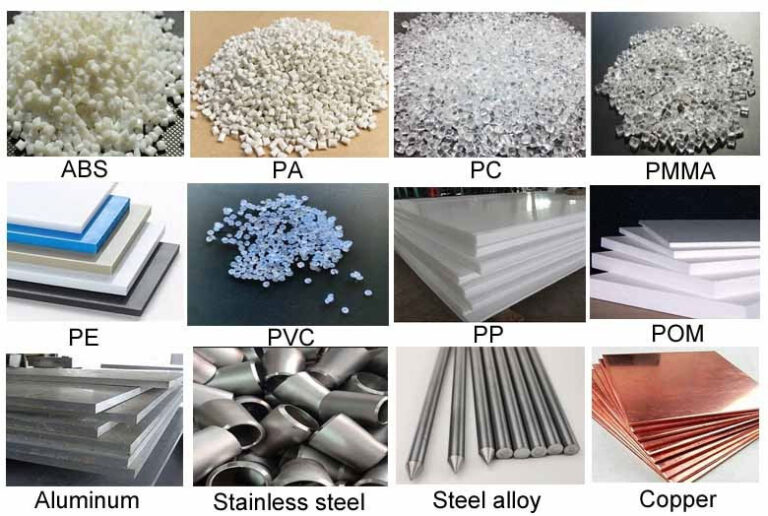

Prototypes are classified by material: plastic prototypes, silicone prototypes, metal prototypes, and clay prototypes.

Molds

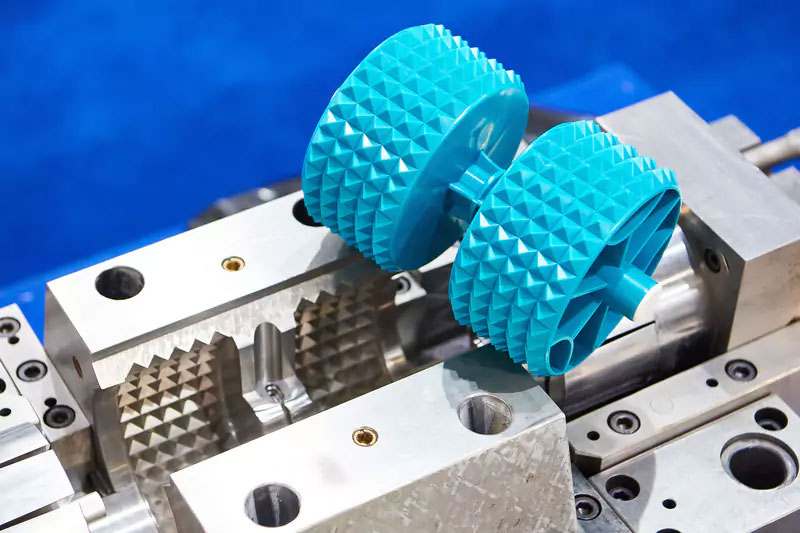

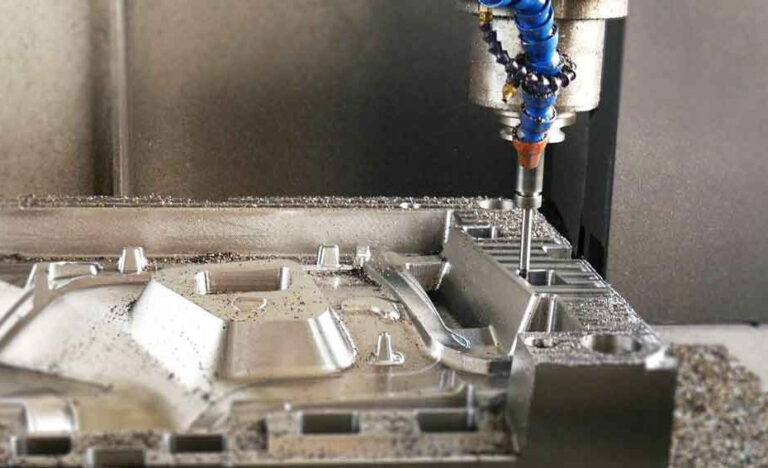

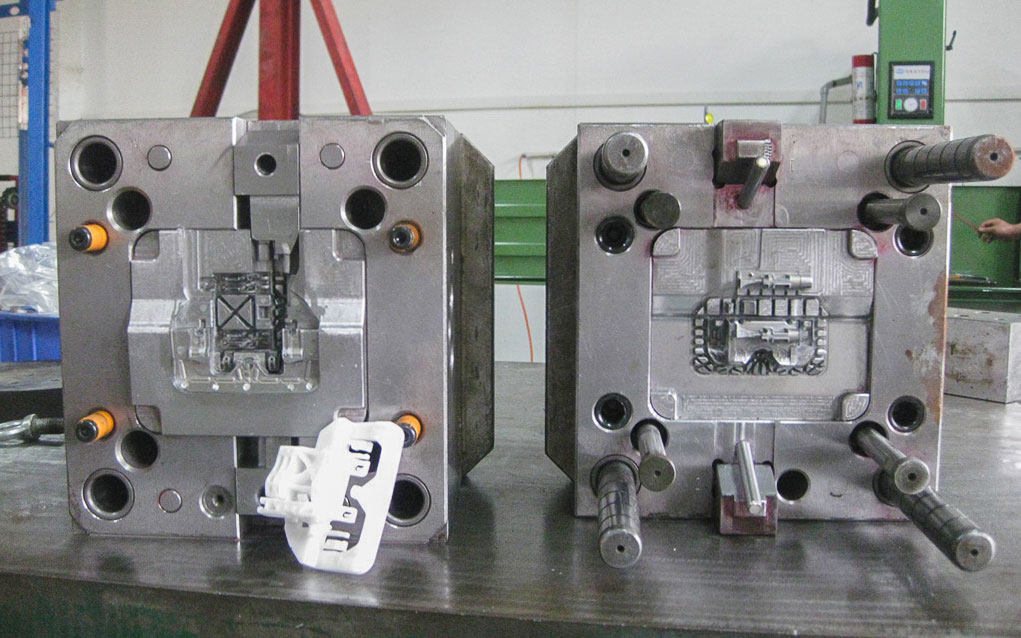

Molds refer to various molds and tools used in industrial production to obtain the required products by injection molding, blow molding, extrusion, die casting or forging, smelting, stamping and other methods.

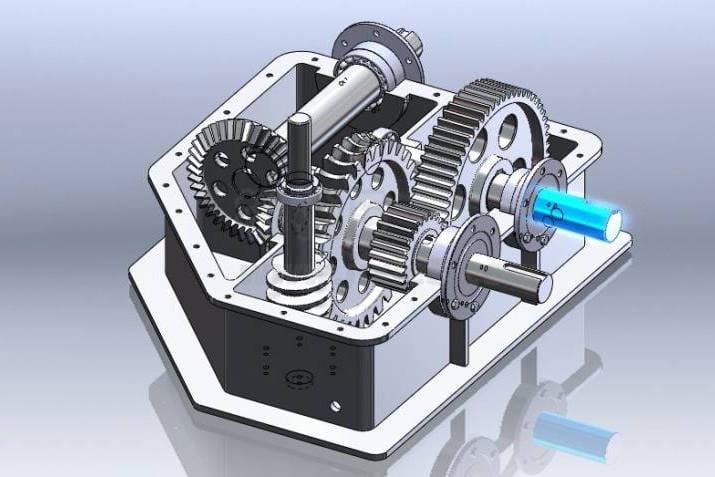

In short, a mold is a tool used to make shaped objects. This tool is made up of various parts, and different molds are made up of different parts.

It mainly realizes the processing of the shape of objects by changing the physical state of the molded material, and is known as the “Mother of Industry” .

For example, common household appliances such as televisions, mobile phones, telephones, communication equipment such as drinking cup shells, etc. are produced by injecting heated plastic into a mold and cooling it into shape. Rice cookers are also made by pressing a metal flat plate into this shape with a mold.

The mold has a specific contour or inner cavity shape. The mold is a precision tool with a complex shape. It bears the expansion force of the blank and has high requirements for structural strength, rigidity, surface hardness, surface roughness and processing accuracy. The development level of mold production is one of the important indicators of the level of mechanical manufacturing .

The cost of manufacturing physical molds is generally very high. A large mold set costs hundreds of thousands, hundreds of thousands, or even millions of dollars. Especially in the medical industry, molds worth millions are very common.

If there are unreasonable structures or other problems during the installation of the mold, the loss will be great. Therefore, we usually use hand plates to confirm the appearance, structure and function first, and then open the mold for mass production after confirming that there are no problems.

Classification of molds:

- Hardware molds are divided into stamping molds (such as punching molds, bending molds, drawing molds, hole-turning molds, shrinkage molds, undulating molds, bulging molds, shaping molds, etc.), forging molds (such as die forging molds, upsetting forging molds, etc.), extrusion molds, extrusion molds, die-casting molds, forging molds, etc.

- Non-metal molds are divided into plastic molds, inorganic non-metal molds, sand molds, vacuum molds and paraffin molds, etc.

Summary

So to sum up, the prototype is used as samples to test the product while the mold is for producing products composed of various parts. Molds are the mother of industry. Do you get it now?