What Is Plastic Shrinkage?

Plastic shrinkage refers to the percentage difference between the dimensions of a plastic part at molding temperature and after it is removed from the mold and cooled to room temperature. It reflects the extent to which a plastic part shrinks after being removed from the mold and cooled. Factors influencing plastic shrinkage include the type of plastic, molding conditions, and mold structure. Different polymer materials have different shrinkage rates. Furthermore, plastic shrinkage is closely related to the part’s shape, the complexity of its internal structure, and the presence of inserts.

Influencing factors:

Influence of molding process on shrinkage of plastic products

(1) The molding temperature remains unchanged, the injection pressure increases, and the shrinkage rate decreases (effectively reducing the appearance of bone marks and internal glue shortages, but pay attention to flash) ;

(2) As the pressure increases, the shrinkage rate decreases;

(3) As the melt temperature increases, the shrinkage rate decreases (increasing the melt temperature is conducive to the plastic flowing and filling the cavity in time) ;

(4) The mold temperature is high and the shrinkage rate increases (the temperature is too high and the cooling time is insufficient) ;

(5) The shrinkage rate decreases when the holding time is long, but the shrinkage rate is not affected after the gate is closed;

(6) Long in-mold cooling time reduces shrinkage (in-mold cooling is conducive to shaping, while out-mold cooling is prone to thermal expansion and contraction) ;

(7) When the injection speed is high, the shrinkage rate tends to increase slightly, but the impact is small;

(8) The molding shrinkage is large, and the post-molding shrinkage is small. The post-molding shrinkage is large in the first two days and stabilizes after about a week.

The influence of plastic structure on product shrinkage

(1) Thick-walled plastic parts have a greater shrinkage rate than thin-walled plastic parts (but for most plastics, 1mm thin-walled parts have a greater shrinkage rate than 2mm thin-walled parts. This is because the resistance of the melt in the mold cavity increases, so the overall wall thickness should be uniform) ;

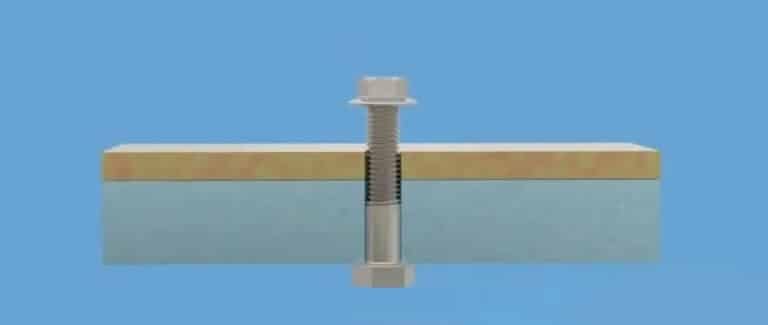

(2) The shrinkage rate of plastic parts with inserts is smaller than that without inserts;

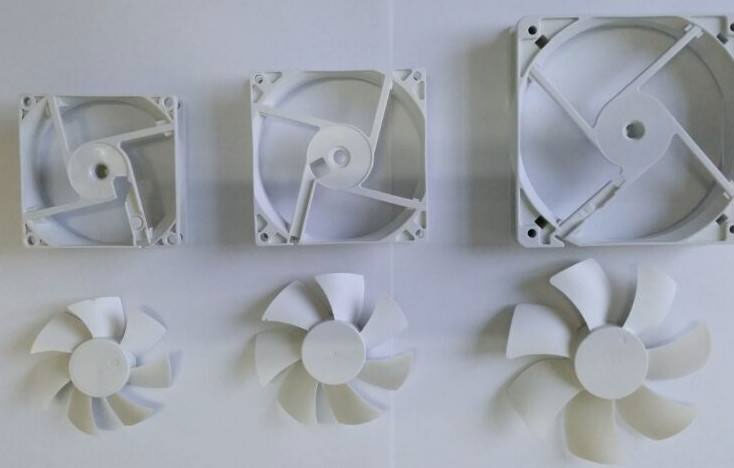

(3) The shrinkage rate of plastic parts with complex shapes is smaller than that of plastic parts with simple shapes (appropriate addition of reinforcing ribs can improve the shrinkage rate) ;

(4) The shrinkage rate of plastic parts in the height direction is generally smaller than that in the horizontal direction;

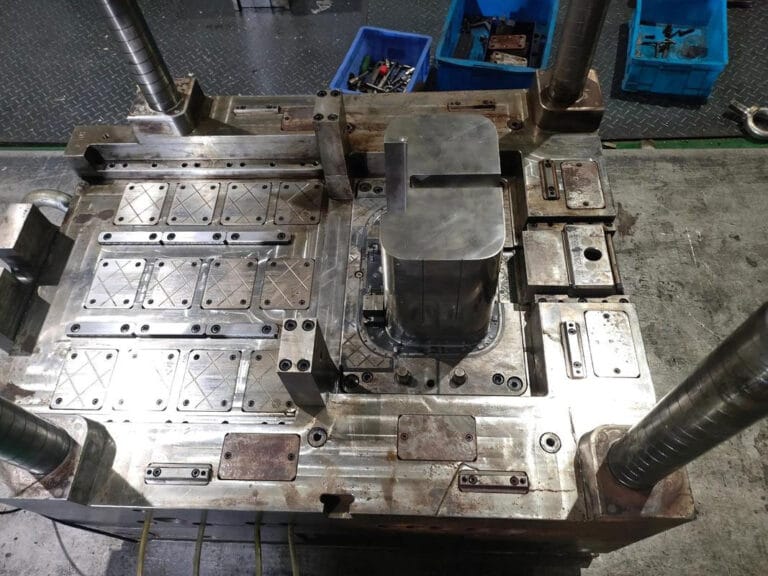

Influence of mold structure on shrinkage of plastic products

(1) Large gate size for plastic injection and reduced shrinkage (when assembling multiple molds, pay attention to the reasonable design of runner and gate size to ensure that the plastic fills the mold cavity at the same time) ;

(2) The shrinkage rate in the direction perpendicular to the gate decreases, while the shrinkage rate in the direction parallel to the gate increases;

(3) The shrinkage rate is smaller away from the gate than near the gate (so pay attention to the water channel cooling design near the gate) ;

(4) The shrinkage rate of the plastic part with mold restrictions is small, and the shrinkage rate of the plastic part without restrictions is large.

The influence of plastic properties on product shrinkage

(1) The shrinkage rate of crystalline plastics is greater than that of amorphous plastics;

(2) Plastics with good fluidity have small molding shrinkage;

(3) Adding fillers to plastics significantly reduces the molding shrinkage (for example, adding glass fiber) ;

(4) Different batches of the same plastic will have different molding shrinkage rates.

The following figure shows the commonly used shrinkage rates for most plastics:

(For reference only, the specific value depends on the specific brand of plastic)

| Material | Shrinkage Rate | Material | Shrinkage Rate | Material | Shrinkage Rate |

|---|---|---|---|---|---|

| ABS REV | 1.006 | PA 6 | 1.010-6 | TPE+HIPS | 1.020 |

| ABS+PC | 1.0055 | PA 101 | 1.015 | NORYL SEI\RIVAL | 1.005 |

| ABS SIEMENS | 1.005 | PA 66 | 1.014 | AC | 1.020 |

| ABS MAPED | 1.0045 | PA 12 | 1.012 | PETC\Transparent Eng | 1.004 |

| ABS 10%GF | 1.003 | PA 6+30%GF MAPED | 1.004 | PBT 2002 | 1.018 |

| AS\SAN | 1.004 | PA 66+30%GF | 1.004 | PBT 6302 | 1.010 |

| CAB\CAP | 1.005 | PA 66+50%GF | 1.003 | ACRYLIC | 1.005 |

| BS\K BATTS | 1.018 | PVC | 1.015-9 | PPE | 1.006 |

| BS\K YAQIAN | 1.006 | PVC\Flexible | 1.020-5 | PPE+PS | 1.005 |

| PBT 2002 | 1.018 | PPO GB6401 | 1.005 | PETG | 1.004 |

| PBT 6302 | 1.010 | PPO\GATEHILL | 1.006 | PES | 1.006 |

| EVA\Rubber | 1.020 | POM\M90-94 | 1.019 | PPS\WHIRLPOOL | 1.004 |

| PE\HD | 1.025 | POM\THOMSON | 1.018 | GP | 1.008 |

| PE\LD Soft COLDEN | 1.020 | POM\CASIO | 1.020 | PS+30%GF | 1.006 |

| PC\Bulletproof | 1.006 | PP\XI | 1.018 | PS\GP Hard | 1.004 |

| HIS | 1.005 | PP\Flame Retardant | 1.014 | PS\HI\BATTS Unbreakable | 1.005 |

| PC 124 | 1.006 | PP\WHIRLPOOL | 1.010 | PU | 1.015 |

| PC+10%GF | 1.003 | PP+20%GF | 1.012 | VALOX\KI | 1.015 |

| PC+PET | 1.006 | PP+TALC\KI | 1.009 | ZYTEL 406 | 1.015 |

| PSU | 1.005 | PCT+30%GF | 1.003 | CA\Acidic Glue | 1.005 |

| PBT | 1.015 | PET+30%GF | 1.002 | AIM 4800 | 1.005 |

| PBT+30%CF&ABS | 1.005 | PET+20%GF | 1.003 | KRATON\Artificial Rubber | 1.008 |

| PF | 1.008 | PMMA\CASIO | 1.003 | TPE | 1.015 |

| PPS+40%GF | 1.003 | PMMA\Acrylic | 1.005 | ZYTEL 406 | 1.015 |

- As can be seen from the table, among the commonly used plastics, PE, PBT, PA, POM, PP, TPE, PU, etc. have relatively large shrinkage rates.

- As can be seen from the table, the shrinkage rate of some plastics is significantly reduced after adding (GF) glass fiber.

- As can be seen from the table, the shrinkage rates of different brands of the same plastic are different.

Measures to prevent shrinkage in structural design:

- If the appearance part is not a load-bearing part, try to add as few bones as possible inside, especially deep bones. If bones must be added, the thickness of the bones should not exceed half of the wall thickness, and the maximum should not exceed two-thirds.

- If the appearance needs to be high-gloss or electroplated, try to add as little bone as possible inside.

- The screw column of the appearance part needs to have a crater at the root, the inner hole needs to be properly hollowed out with glue, and the outer diameter of the column should not be too large.

- For the screw columns on the inclined surface of the appearance parts, since the roots and side walls are too thick, the roots should be inclined as much as possible to prevent shrinkage.

- Pay attention to the thickness of the stoppers and buckles of the exterior parts, and the thick and thin parts need to be chamfered and transitioned smoothly.

- When selecting materials for exterior parts, try to use plastics with low shrinkage rates.

- If shrinkage cannot be avoided after the above steps, the shrinkage can be covered up by spraying oil later.