Introduction

Prototype production is primarily categorized into four methods: 3D printing, CNC milling, silicone molding, and hand engraving. Hand engraving dominated the early stages of the prototype industry, but was gradually replaced by CNC milling in the early 1990s.

After more than 20 years of development, 3D printing technology has matured, and since 2016, it has been gradually replaced by 3D printing. While 3D printing offers low cost and high speed, it also has inherent limitations. Exceptions in precision and material strength remain elusive. 3D printing still cannot meet the demands of prototypes requiring high precision, strong physical properties, and superior surface finishes. Each prototyping method has its own advantages and disadvantages.

Today, we’ll share the prototyping process using CNC milling. We hope this can help you!

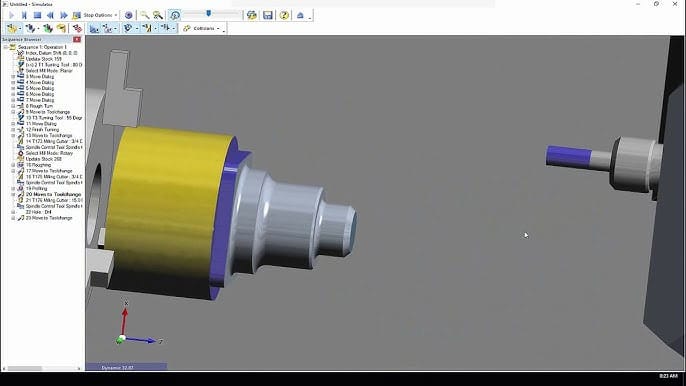

1, CNC programming:

Programming is the first step in CNC prototype production. When engineers receive the drawings, they will first review the drawings. Based on the product process, they will determine whether CNC machining requires disassembly and edit the tool path to ensure that the product’s appearance is not affected.

The tool type is selected according to the material properties, and finally the engraving and milling speed is set according to the equipment performance.

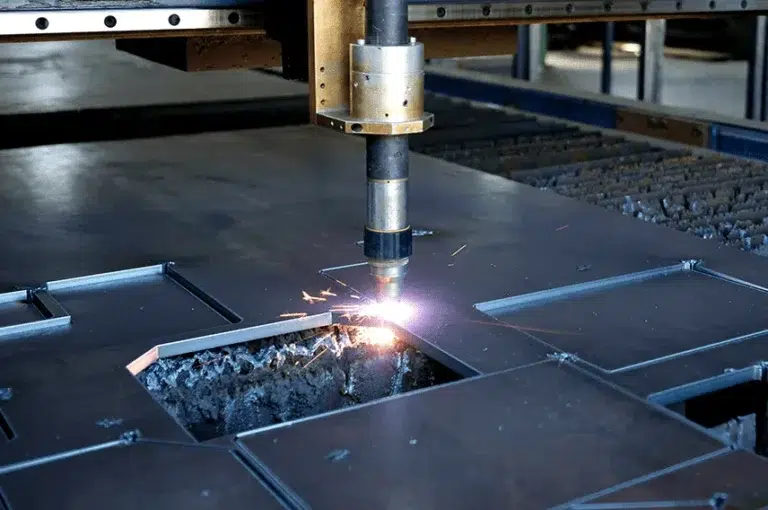

2, CNC Machining:

The engineer’s program is sent to the CNC machining center. The operator selects the appropriate materials and tools based on the program, sets the workpiece’s machining coordinates, and then processes the product. Dedicated personnel are required to monitor the machining process, as problems such as tool melting and tool breakage can occur.

If these issues are not addressed promptly, the workpiece will be scrapped. Some older equipment lacks a tool magazine and requires manual tool changing. Without personnel on duty, the machine will stop and wait for material to be delivered.

3, Manual adaptation:

After CNC processing, there will be a lot of burrs on the surface, which are unavoidable, so they need to be manually processed. There are also inherent defects in CNC processing, and the right-angle area cannot be fully processed in place.

This also requires manual use of specific tools to manually clear the angles and splice, and then assemble and adapt.

4, Polishing:

CNC machined products will have knife marks on their surface, so each prototype needs to be polished manually. After receiving the product, the polishing master will first check the 3D drawing, analyze the key points of the product’s appearance, and try to show the product’s edges, lines, gaps, etc.

5, Surface treatment:

The biggest advantage of CNC prototype is that its surface effect is closer to the final mass production effect. The product sprayed with color according to the color plate or PANTONG provided by the customer is put into the oven for baking. The baking time will vary according to the characteristics of the material and paint. After the paint is dried, UV will be sprayed. UV can not only protect and reinforce it, but also beautify the paint. In addition to spray painting, general surface treatments include silk screen printing, laser engraving, oxidation, electroplating and other methods.

6, Finished product assembly:

Both the appearance prototype and the structural prototype need to be assembled. The first thing is to check whether the product accessories are complete, and then carefully assemble them according to the 3D drawings and process instructions provided by the customer. Pay special attention to the assembly relationship of the product and the gaps between parts.

7, Quality inspection:

All prototypes must undergo quality inspection before shipment. Of course, quality inspection is not only in the last link. The quality of the prototype is mainly controlled in each process link, so as to ensure that the product is delivered on time and the customer receives a satisfactory product.

The above CNC prototype production process is some knowledge summarized by Gaofeng Prototyping based on 12years of prototype experience. We hope it will be helpful to you.