Introduction

The rise of the Industrial Revolution in the 18th century marked a new era of collaborative work between humans and machines in the manufacturing industry, changing the previous reliance on inefficient and error-prone manual casting. Today, thanks to the leap in digital technology, we are able to witness efficient and high-precision manufacturing technology, among which CNC milling is a model widely used in complex parts processing. As a machinist, do you have a thorough understanding of milling? Today, Gaofeng has specially sorted out the basic knowledge about CNC milling, hoping to help everyone~

What is CNC Milling?

CNC milling is a subtractive manufacturing process in which a computer-controlled cutting tool gradually removes material from a workpiece to create a desired shape or object. This process is achieved by using a machine known as a CNC milling machine or CNC mill. It is a widely used machining process, others being CNC turning and CNC drilling.

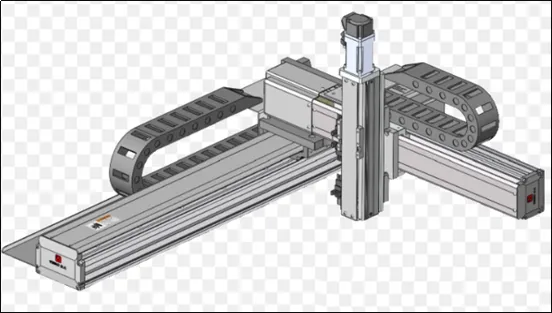

Parts of CNC milling machines

To better understand the process of CNC milling, it is necessary to understand the parts of CNC milling. The parts of different milling machines vary depending on the manufacturer, type, and capabilities. However, there are a few parts that are fundamental to every CNC milling machine:

Spindle: The spindle holds the cutting tool in place

Control Panel: This is where the operator controls the machine. This is where the computer interface is located

Uprights: The uprights are the main frame and support of the machine. They hold the other components in place.

Saddle: The saddle is fixed to the pillar of the machine. It supports the work table.

Work Table: The work table is located on top of the saddle. This is where the operator places the workpiece and uses the workholding devices.

Foundation: Foundation is something that provides support to the entire machine on the ground.

How CNC Milling Works

Prior to the incorporation of CNC, controls in milling machines were performed manually. This gave a lot of room for error. The final product appeared in the machinist’s mind or vision, similar to the way an artist paints a picture. However, with the addition of CNC, milling became a highly precise and accurate process involving a number of steps. There are four sequential steps involved in creating a CNC milled part:

- Design 3D Models

- Convert the model to machine code

- Setting up the milling machine

- Actual grinding

Design 3D Models

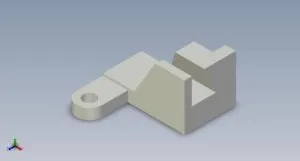

The first step in the CNC milling process is to design a CAD (Computer Aided Design) model of the part to be milled. This is performed using a CAD program available for this purpose. Any features that are to be part of the final product must be indicated in the design. We have compiled some standards and guidelines that every designer should follow to make a correct CNC milling design.

Conversion from CAD to G-Code

CNC milling machines cannot understand CAD files in their native format. Instead, they rely on digital instructions known as G-Code, which instruct them on how to move in 3D space. Therefore, it is necessary to convert the CAD model into G-Code. This is where computer-aided manufacturing (CAM) programs come in. After completing a CAD model, the designer exports it to a CAM program, which reads the model and converts it into the corresponding G-Code.

Setting Up a CNC Mill

Next comes machine setup. Before running a CNC program, an operator needs to set up the CNC mill by attaching the workpiece to the mill’s work surface; securing the appropriate cutting tool to the mill’s arbor; and preparing any necessary cutting fluids.

Performing the actual milling

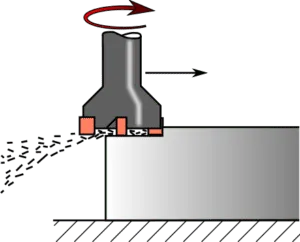

After setting up the machine, the operator starts the milling process through the machine interface. The machine begins the actual milling by rotating the cutting tool around its axis at very high speeds of up to several thousand rpm (revolutions per minute). Depending on the nature of the milling machine, the cutting action on the workpiece is achieved through one of the following movements:

- The cutting tool moves on a fixed workpiece

- The workpiece is fed into the stationary, rotating cutting tool

- Both the workpiece and the cutting tool move relative to each other

One of the following operations is continued intermittently, taking small cuts at a time, until the machine produces the desired object.When the tool is in contact with the workpiece, its cutting edge repeatedly cuts into and leaves the surface of the workpiece, effectively scraping chips from the workpiece through shear forces.

CNC Milling Terminology

Certain terms used in CNC milling may mean other things in other contexts. Knowing these terms will help you better understand your CNC machinist or designer.

Cutting Tools

The cutter is a removable part of the CNC mill that performs the cutting action. The cutters used for CNC milling usually have multiple cutting points. This is because, during the milling process, the cutter moves perpendicular to its axis of rotation. There are various types of cutting tools, which vary according to the material, form, number of flutes, and location of the cutting edges. The cutter selected for the milling process depends on the material to be milled.

speed

Speed in CNC milling refers to how fast the tool rotates. It is measured in rotations per minute (RPM). The speed can be programmed and it depends on the material being milled. For example, you can mill aluminum at a higher speed than steel.

feed

This is the distance the workpiece or tool moves per revolution. Like speed, you can also program the feed. The feed also depends on the material you are grinding.

Cutting depth

The depth of cut is the distance the tool moves to the workpiece surface. The material also determines this parameter.

Cutting fluid

Because milling is usually a high-speed process, a lot of heat is usually generated due to the friction between the workpiece and the cutting tool. This makes it necessary to use a substance called a cutting fluid to cool them.

Common CNC Milling Operations

There are many milling operations that CNC milling can perform, depending on the type of cutting tool and the machine configuration. The four main CNC milling operations are:

Face milling

In face milling, the tool’s axis of rotation is perpendicular to the workpiece surface. This operation creates a flat surface and requires an end mill with a cutting edge at its tip.

General milling

A cutting tool used for general milling has cutting edges along its entire cutting perimeter. Its axis of rotation is parallel to the workpiece surface. General milling produces features such as holes, slots, and cavities.

Angle milling

In angle milling, the axis of rotation of the tool is at an angle to the workpiece surface. They are called single angle milling cutters. Angled milling produces features like dovetails, chamfers, grooves, etc.

Profile milling

Form milling involves the production of irregular surfaces, contours, semi-circular cavities, beads and curved surfaces. This business uses cutting tools such as fly cutters and form milling cutters.

Other grinding operations include

- Gear cutting, i.e. the production of gear teeth using gear cutting tools

- Simultaneous milling, in which two or more tools perform the same or different operations on a single workpiece simultaneously, is the fastest milling operation.

- Cross-milling, using two tools to simultaneously mill parallel surfaces of a workpiece in one cut

CNC Mill Types

Based on the direction of the spindle, CNC milling machines can be divided into two types: vertical and horizontal. Before choosing between these two types of milling for a milling project, the operator must consider the needs of the project, such as the shape and size of the part and the number of surfaces to be milled. For example, while vertical mills offer more versatile machining options, horizontal mills are better suited for heavy and long workpieces.

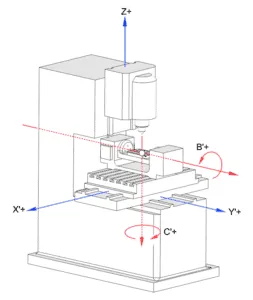

Another major classification of CNC milling machines is based on the number of axes and axis configuration. In CNC milling, an axis refers to the direction of movement of the workpiece or tool. In our network, we perform multi-axis milling operations, including 3-axis, 4-axis, and 5-axis milling. We can quickly and accurately produce parts from simple shapes to complex geometries based on your design. 3-axis and 5-axis CNC mills are the most popular types of CNC milling machines.

3-axis CNC rolling mill

A 3-axis CNC milling machine has three degrees of freedom for the tool or workpiece. This means they can move in three linear directions; the X-axis (left to right), the Y-axis (front to back), and the Z-axis (up to down). In order for the cutting tool to reach certain areas of the workpiece, the workpiece must be manually repositioned.

Advantages of 3-axis CNC milling

- The process is easy to program and can produce parts with simple geometry and high precision.

- Its production capacity is high

- Relatively low processing cost per part

- 3-axis CNC mills are cheaper than their 5-axis counterparts

Limitations of 3-axis CNC milling

- For some processes that require more tools, the need to constantly reposition the workpiece can reduce accuracy

- The tool cannot access certain areas of the workpiece

- Complex geometries and designs are more difficult to achieve with a 3-axis CNC mill than with a 5-axis CNC mill

5-axis CNC rolling mill

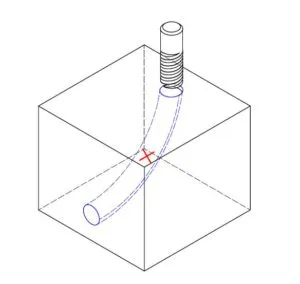

In addition to the three linear axes that are available in its 3-axis counterpart, a 5-axis CNC mill also has two rotary axes. In most milling machine configurations, the tool can only move along three linear axes. The workpiece performs the remaining two rotational movements, giving the cutting tool access to another area.

5-axis CNC mills can be further categorized into indexed and continuous. In an indexed 5-axis mill, the tool must temporarily stop moving while the workpiece rotates. However, in a continuous 5-axis mill, the tool does not need to stop. While the tool moves, the workpiece rotates simultaneously.

Advantages of 5-axis CNC milling

- It eliminates the need to manually reposition the workpiece

- It produces parts with some very complex geometries and is designed with very high precision

- The surface of the 5-axis CNC milled parts is very smooth. There are almost no machining marks.

Disadvantages of 5-Axis CNC Milling

- The machining cost per part of variable 5-axis CNC milling and continuous 5-axis CNC milling is 60% and 100% higher than that of 3-axis milling respectively.

- 5-axis CNC mills are bulkier and more expensive than their 3-axis counterparts

Materials that can be CNC milled

Milling is a very versatile process that is suitable for many materials. When selecting a material for CNC milling, many factors should be considered, such as cost and material properties. Material properties include tensile strength, heat resistance, hardness, chemical resistance, and shear strength.

Likewise, the material selected determines many aspects of the milling process, including part design, cutting tools, cutting speeds and feeds, cutting fluids, and depth of cut. Here are some materials commonly used for CNC milling:

Metal

Metals and metal alloys are the most commonly used abrasive materials. This is because they are widely used in several industries. Commonly ground metals are aluminum and its alloys, various types of steel, brass, copper, titanium and bronze.

plastic

Next is plastics due to its popularity in the paper industry. They also have desirable properties and are widely used. Polymers such as ABS, PEEK, polycarbonate, and nylon are some of the plastics that are frequently CNC milled.

Other Materials

Wood, glass and elastomers are also suitable materials for CNC milling.

Advantages and applications of CNC milling

Here are some of the benefits that make CNC milling a great choice for machining your parts.

Scalability

CNC milling is suitable for a wide range of production volumes, whether it is a one-off custom project or small to large-scale production runs. Coupled with its repeatability and speed, the scalability of CNC milling makes it ideal for prototypes or large-scale production. CNC milling is excellent for large-scale production of identical units, as production costs decrease exponentially as the number of units increases.

Fast turnaround time

The inclusion of CAD and CAM programs in CNC milling significantly reduces the time it takes from placing an order to receiving a precisely machined part. Despite the high speeds, accuracy is still maintained.

Accuracy

CNC milling can produce parts with very high dimensional accuracy. Tolerances as tight as 0.025 mm are feasible. This high accuracy is critical in the aerospace and automotive industries.

Material selection

There are over 50 engineering materials that can be CNC milled, provided the correct tool and cutting speed are used. Whether your material is metal, plastic, wood, glass, or even stone; if you have an application, it is most likely CNC milled. In addition, CNC milling has little or no effect on material properties.

Versatility

In addition to being able to create a variety of shapes, CNC milling can also accurately machine a variety of features, including cavities, threads, bevels, grooves, cavities, etc.

Limitations of CNC Milling

The cost of complex geometries

In subtractive manufacturing processes such as CNC milling, costs increase with the amount of material the machine needs to remove. Therefore, the cost of milling complex geometries that require a lot of material removal increases with the level of complexity.

Workholding and tool access restrictions

During the CNC milling process, it is crucial to hold the workpiece in place. However, this creates some limitations because the tool cannot access the part of the workpiece that is held. In this case, the workpiece needs to be repositioned manually. This increases the processing time and also increases the possibility of errors.

Features that cannot be milled

Certain features, such as curved holes, straight inside edges, and walls less than 0.5 mm thick, cannot be milled. While we encourage you to avoid such features when designing for CNC milling, they are sometimes necessary for the function of the part. In these cases, other forms of grinding can be used.

Material loss

Compared to forming and additive manufacturing processes, CNC milling produces a lot of waste material as swarf. If you can’t recycle these, they can have serious environmental and cost impacts.

Industries that require CNC milling

Many industries rely on CNC milling to produce parts. Likewise, individuals often need this process. In addition to its high speed and high precision, the scalability and versatility of CNC milling make it almost indispensable to subsequent industries.

- space

- electric

- Aerospace

- car

- manufacturing

- physical education

- robot

- compression

- equipment

- Medical

- food

- tool

Alternatives to CNC Milling

While CNC milling is extremely versatile and ubiquitous, it may not be suitable for every manufacturing application. Other machining methods may prove to be more cost-effective and suitable for your project. Some of these methods are listed below:

- Mechanical processes involving machine tools – drilling and turning

- Machining without machine tools – abrasive jet machining, ultrasonic machining and water jet cutting

- Non-machining – electrical discharge machining (EDM), plasma cutting, electrochemical deburring and laser cutting