The role of liquid silicone cold runner

Liquid silicone molds use cold runners, which use less material, can save production cycles, and reduce material loss. However, the use of cold nozzle synchronization will increase the complexity of the mold and the mold cost will also increase.

Key points of cold runner design

The cold runner is one of the important processing features of liquid silicone. The rationality of its design directly affects the stability of production and product quality.

1. Sealing of cold nozzle design

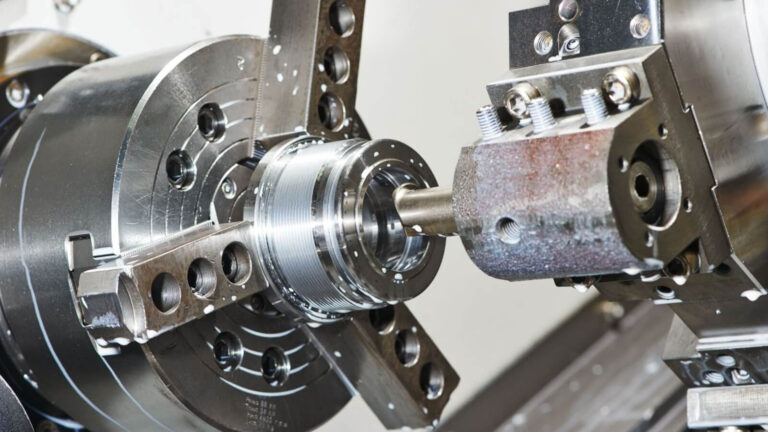

There is a big difference between cold runner molding and hot runner molding. First of all, the cold nozzle needs to be designed with a reasonable water channel. Each cold nozzle cooling water channel is controlled separately to ensure the temperature of each cold nozzle is consistent and balanced. A reasonable insulation layer needs to be set between the cavity and the cold runner to isolate the temperature transfer. Therefore, the valve core of the cold nozzle needs to choose a suitable steel material, which must be both corrosion-resistant and have a certain rigidity. The nozzle head needs to be made of high-quality alloy steel material, on the one hand, to meet the good thermal insulation effect, and on the other hand, to have a certain strength. The sealing ring for sealing glue and the sealing ring for water sealing need to be equipped with special sealing rings to ensure their sealing, as well as the processing accuracy of each valve needle and nozzle head, to reduce needle jamming and glue leakage.

2. Cold nozzle wall thickness design

The wall thickness of the cold nozzle affects its strength, but it also affects the cooling effect. Therefore, the wall thickness of the cold nozzle should not only consider the rationality of the cavity layout and ensure the wall thickness, but also its cooling effect. Generally, it is designed to be at least 3mm to ensure its strength and cooling effect.

3.Design of cold nozzle closing system

The cold nozzle design adopts a needle valve closing system, and the glue port is generally designed to be between 0.5-0.8mm . The valve needle system needs to be designed with a highly adjustable structure to facilitate the adjustment of the needle valve to fine-tune the flow rate.

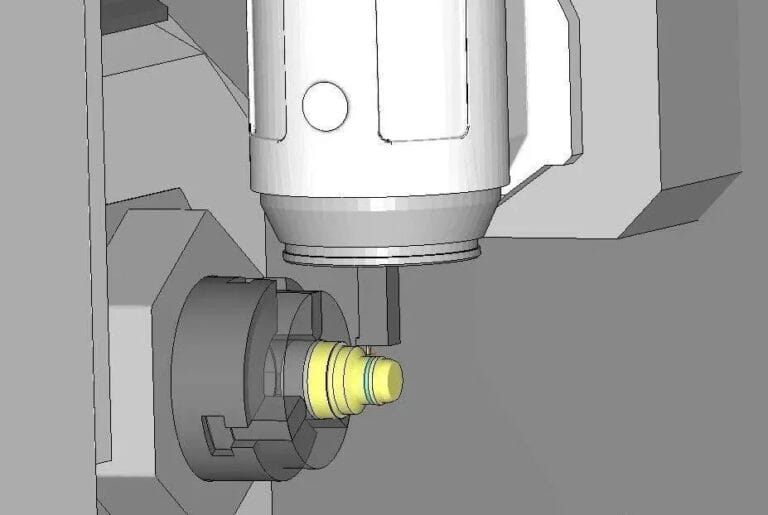

4. Design of micro-control system for cold nozzle

For injection molding of lightweight products, when the product weight is small, it is necessary to design a precise glue feeding control system to ensure the accuracy of glue feeding and the controllability and adjustment of the glue amount. Our company currently uses a turbine rod mechanism to control the glue output of the valve needle.

5.Cold runner design

The cold runner is open to ensure smooth surface, no dead corners, and easy cleaning and maintenance.

In short, a good cold runner design must consider how to ensure processing accuracy and balance, as well as its sealing and mass production stability.