A review published in Nature Communications by researchers from the University of Colorado and Georgia Institute of Technology outlines how additive manufacturing (AM) and computational design are enabling a new generation of high-performance composite materials. The paper surveys developments in 3D printing of composites reinforced with nanoparticles, short fibers, and continuous fibers, as well as optimization methods for tailoring structure and functionality.

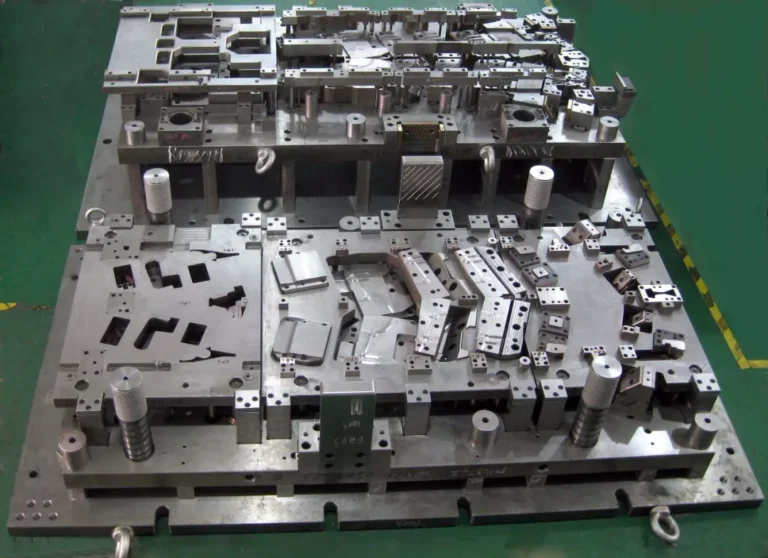

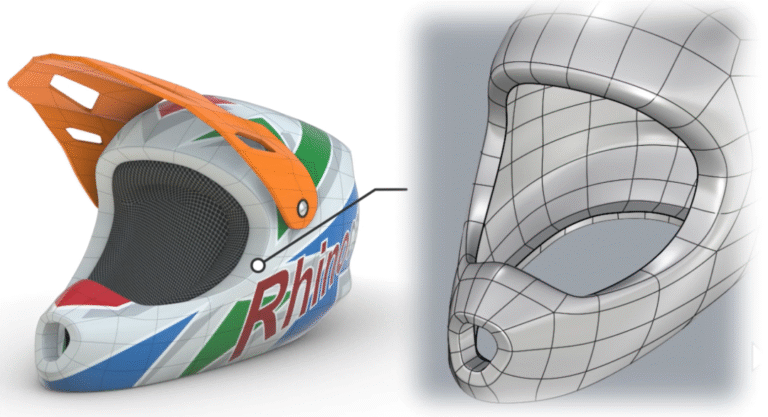

The fusion of additive manufacturing and topology optimization enables precise control of fiber orientation, material distribution, and shape design, enabling structural, thermal, electrical, and responsive behaviors not achievable with traditional manufacturing. These methods eliminate the need for tooling, reduce the cost of low-volume production, and enable the integration of complex or multi-material features. Applications span aerospace, energy, robotics, and biomedicine.

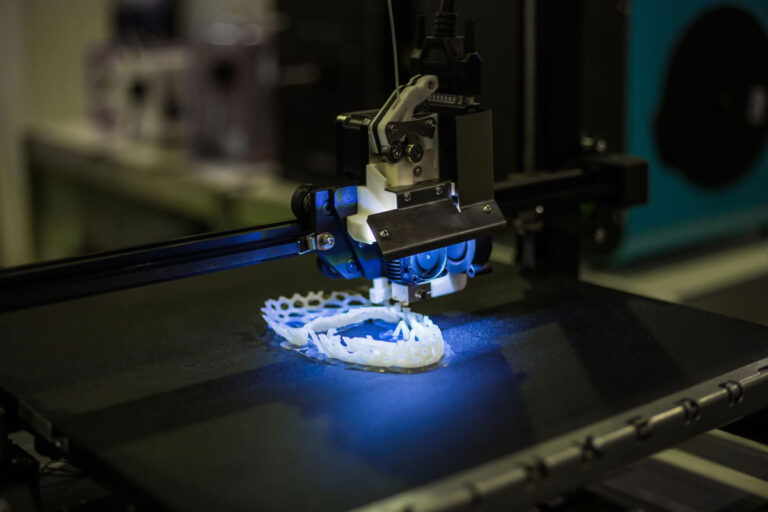

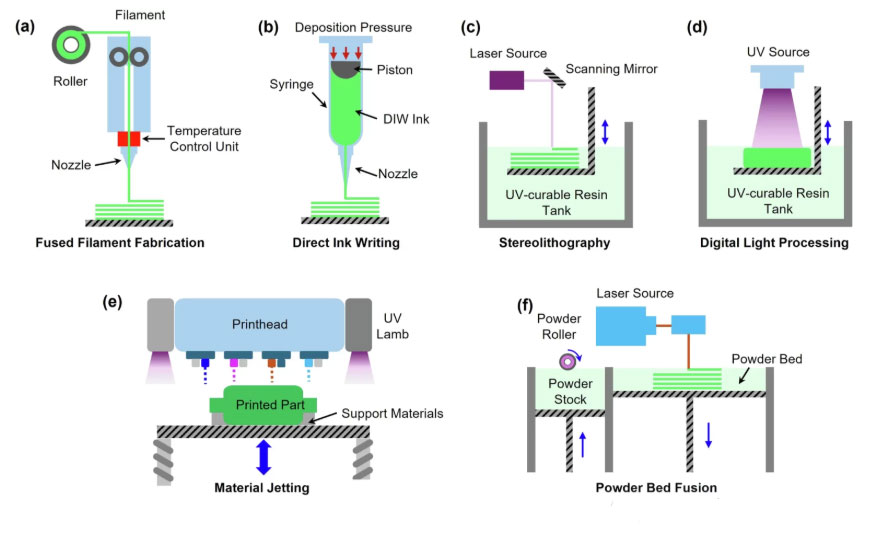

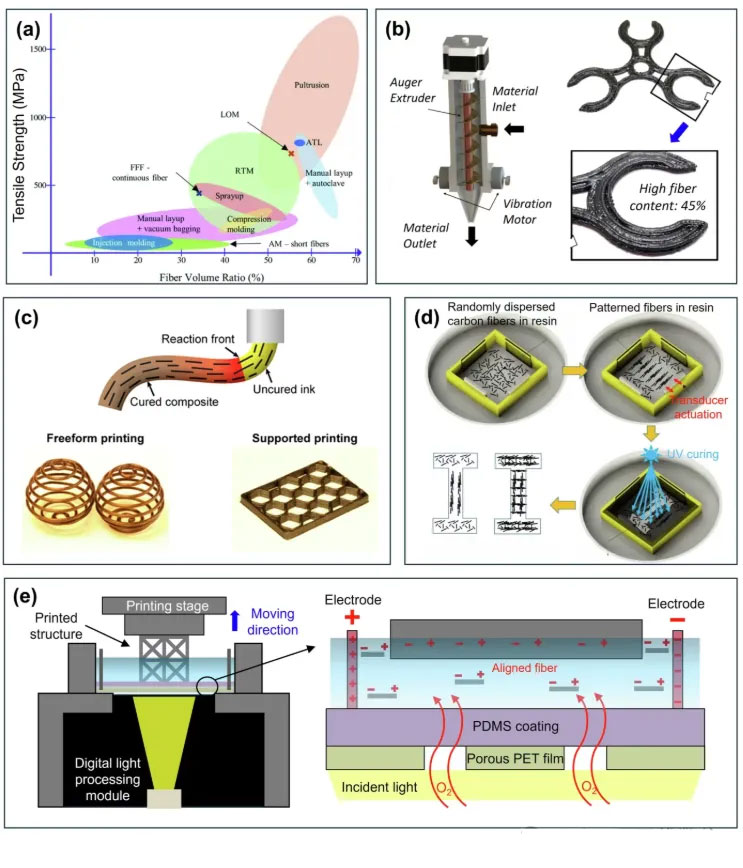

Material extrusion, photopolymerization, and powder bed fusion are the most widely used technologies for printing composites. In fused filament fabrication (FFF) and direct ink writing (DIW), short fibers are dispersed into a thermoplastic or curable resin. Photopolymer-based processes, such as stereolithography and digital light processing, enable high-resolution printing of composites with functional nanoparticles. However, high filler content can limit light penetration. Methods such as ultrasonic alignment and frontal polymerization are used to address this limitation and improve matrix curing.

Milled and chopped fibers improve mechanical strength, but uniform dispersion remains a challenge. Frontal polymerization has been used to facilitate the curing of composites with opaque fibers. In DIW systems, clog-resistant nozzles and shear-thinning inks allow for higher fiber loadings. DLP systems use ultrasound or electric fields to align fibers during printing, enhancing directional properties.

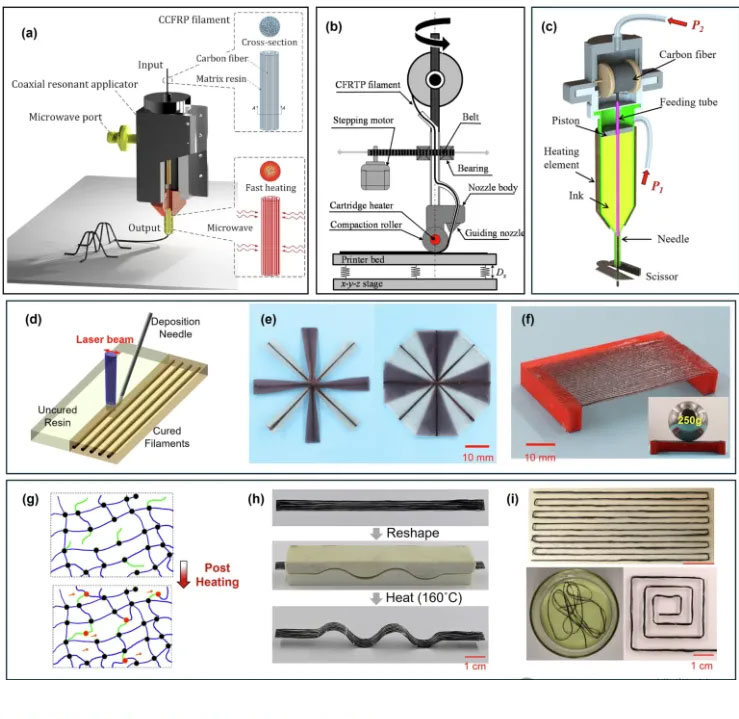

Continuous fiber reinforcements offer the highest mechanical properties. In FFF systems, fibers are integrated using in-nozzle impregnation or pre-impregnation of filaments. Microwave-assisted heating, hot compaction, and laser-assisted consolidation are used to strengthen interlaminar bonds and reduce voids. UV-curable resin systems developed by Continuous Composites Inc., a US-based continuous fiber printing company, use post-deposition curing to cure thermoset composites in real time. These methods have demonstrated improved structural fidelity and reduced support requirements.

Another approach involves printing continuous fibers in a resin bath and curing them with a focused laser. This enables real-time variation of fiber volume, matrix material, and geometry. Two-stage UV-cured resins, including a post-heating stage, have increased matrix stiffness by 11 times and introduced repairability and recyclability. Glass-based systems further enhance interfilament bonding and enable thermoset composites to undergo repeated healing cycles.

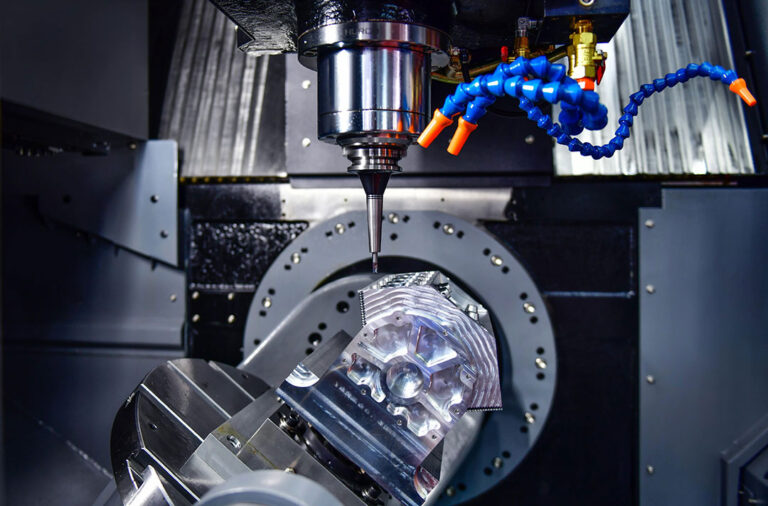

Robotic arm integration expands the geometric flexibility of composite printing. A six-axis robot has been used to deposit UV-curable composite materials along a scanned substrate, enabling fabrication on both flat and curved surfaces. One process combines resin infusion, extrusion, compression, and UV curing to produce continuous fiber-reinforced structures with properties comparable to aerospace-grade laminates.

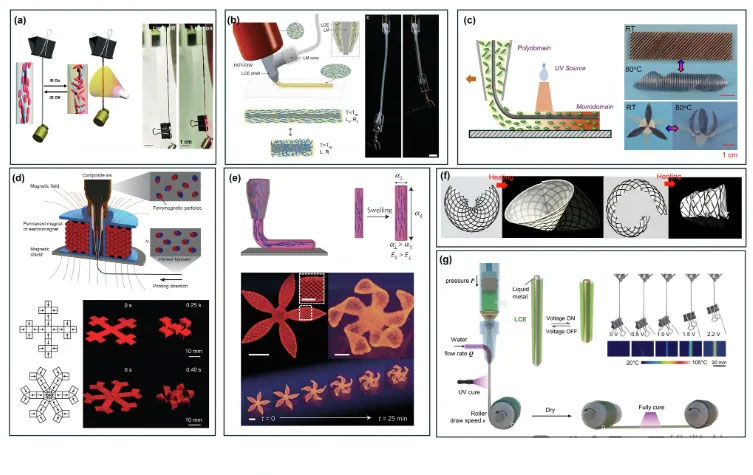

Responsive behavior is introduced through shape-shifting composites based on liquid crystal elastomers (LCEs). These materials deform in response to external stimuli such as temperature, infrared light, or electric fields. The alignment of mesenchymal molecules during DIW enables uniform actuation. Coaxial DIW technology has been used to print hollow LCE fibers filled with liquid metal, enabling electrically actuated deformation. Continuous fibers embedded in the LCE increase actuation force and enable complex motions, including curling, twisting, and folding.

Other deformation mechanisms include embedding magnetic particles that reorient under a magnetic field or embedding shear-aligned cellulose nanofibrils into DIW-printed hydrogels to achieve anisotropic swelling. FFF-printed bilayer structures composed of materials with mismatched thermal expansion coefficients have demonstrated programmable bending. These behaviors can be tuned by fiber placement and orientation during the printing process.

Composite materials with functional thermal and electrical properties are being developed using aligned conductive fillers. Graphite flake composites printed using FFF exhibit enhanced in-plane thermal conductivity, while carbon fiber systems printed using DIW act as strain sensors. Changes in electrical conductivity under mechanical loading allow for structural health monitoring. Continuous fibers are also being embedded in lattice trusses and prosthetic limbs as sensing elements.

Electromagnetic shielding has been demonstrated using PLA-carbon fiber composites, achieving up to 38.5 dB of attenuation. A dual-layer metamaterial structure combining graphene and carbon fiber has achieved a shielding efficiency of 63 dB and an absorption bandwidth of 32 GHz. Energy storage capabilities have been achieved by using carbon fiber as the anode and current collector, with a polymer matrix acting as the cathode and solid electrolyte. This enables structural batteries to combine mechanical support with electrical functionality.

Self-healing properties have been introduced using a variety of strategies. In thermoplastics, reheating causes polymer chains to interdiffuse, closing cracks. Short, continuous carbon fibers have been used as embedded susceptors for microwave-assisted welding, allowing for localized repair. Microcapsule-based systems have been embedded in FFF filaments and matrices to deliver healing agents at the time of fracture, achieving strength recovery exceeding 80%. Glass trimeric networks incorporated into UV-curable thermosets support multiple healing cycles without the need for external capsules and improve interlaminar adhesion in continuous fiber systems.

Topology optimization has become a core tool for structural and functional design. Early frameworks used density-based methods and local volume fraction variables to distribute materials and align fibers based on stress fields. Optimization outputs have been converted into printable fiber layouts through multiscale workflows. Level set methods define shape boundaries and fiber orientation through B-spline control, introducing greater geometric accuracy without the need for post-processing filters.

Functional composite materials designed through optimization exhibit targeted nonlinear deformation, thermal regulation, and magnetic actuation. A DIW-printed robotic fish, designed with topologically optimized fiber layouts, increased its swimming speed by 50% and reduced its turning radius by 55%. Other research has developed magnetically encoded composite materials for shape deformation and cold plates with optimized heat flow based on inlet and outlet positioning.

Particle-based extrusion systems are emerging in large-format applications due to their higher deposition rates and lower material costs. These systems allow for real-time modulation of fiber or filler content, thereby achieving compositional gradients across layers. Robotic arms further enhance the scalability and geometric range of these systems. However, thermal shrinkage, warping, and interlayer adhesion remain key challenges. Future improvements in material formulation, post-processing, and process modeling are needed to advance structure-scale manufacturing.

Sustainable materials are also gaining attention. Natural fibers such as hemp, flax, and jute have been used in bio-based matrices such as polylactide to produce fully biodegradable composites. Although mechanical properties and interfacial compatibility require further investigation, these systems show promise in automotive interiors, packaging, and architectural components.

This review emphasizes the importance of integrating simulation, sensing, and manufacturing. Digital twins, combined with in-situ monitoring, can enable real-time predictive control of the printing process. Advanced models are needed to capture resin curing dynamics, fiber alignment, and mechanical response under complex conditions. Incorporating these into design tools along with process constraints will enable the coordinated optimization of product topology, fiber layout, and printing parameters.