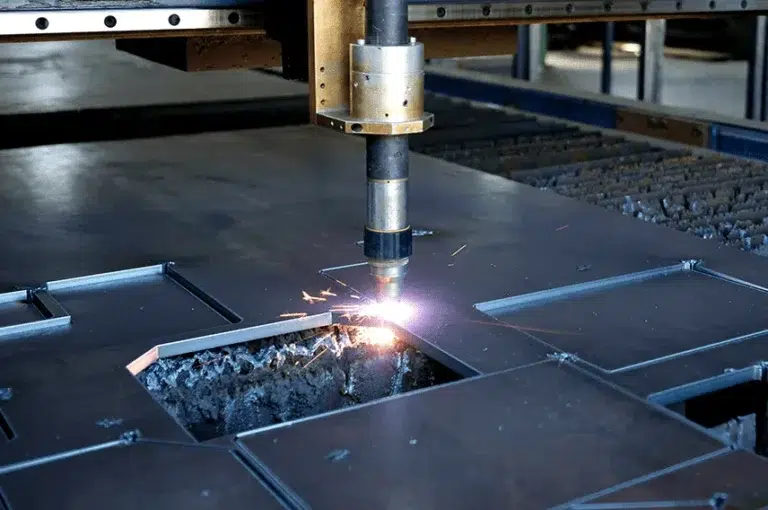

1, Mold hardness: soft mold, hard mold

①Soft mold: The mold steel has been pre-hardened and does not require quenching treatment, but the hardness is relatively low, HB is below 400, the production life is within 500,000 times, and it is widely used.

② Hard mold: The mold steel is annealed and processed in two steps: roughing and finishing. After roughing, it is quenched. The hardness is above HRC48°. After roughing, a machining allowance of about 0.2 is required to prevent the workpiece from deforming after quenching, which may affect the workpiece quality. The production life is more than 500,000 to 1,000,000 times, and small molds are the most commonly used.

2, Mold quality level: Level 1, Level 2, Level 3, Level 4

①First-level mold:

The mold must be able to be opened one million times or more.

The requirements for first-level molds are as follows:

(1) Detailed mold design (including computer graphics and materials);

(2) The mold base hardness must be at least HB280;

(3) The mold core must be hardened to at least HRC50, and all slides and accessories must also be hardened;

(4) The thimble should be placed on the edge of the pipe;

(5) The slide must have a wear-resistant plate;

(6) Temperature control monitors must be installed in the mold, cabinet or row position according to feasibility;

(7) It is recommended to nickel plate all cooling water channels to prevent rust and facilitate cleaning;

(8) It is necessary to add a positioning lock to the parting line.

② Secondary mold:

It must be able to have 500,000 or more mold opening times.

The requirements for secondary molds are as follows:

(1) Detailed mold design is recommended

(2) The mold base hardness must be at least HB280

(3) The mold core must be at least HRC48 hard, and all slides and accessories must also be heat treated.

(4) Temperature control monitors shall be installed on the mold, cabinet or platform according to feasibility.

(5) Positioning lock is necessary for the parting line

(6) The following requirements will be determined at the time of individual request and quotation.

③Level 3 mold:

It must be able to have 250,000 or more mold opening times.

The requirements for the third-level mold are as follows:

(1) Suggest mold design

(2) The mold base hardness must be at least HB165

(3) The mold core must be at least HB280

(4) In addition to the above three basic requirements, the others are considered as optional additional requirements

④Level 4 mold:

Level 4 mold requires about 10,000 times. Generally speaking, there are no special requirements;

The requirements for the fourth-level mold are as follows:

(1) Suggest mold design

(2) The mold base may be made of ordinary copper or aluminum

(3) The mold can be made of aluminum or steel with the customer’s consent

(4) In addition to the above three basic requirements, the others are considered as optional additional requirements

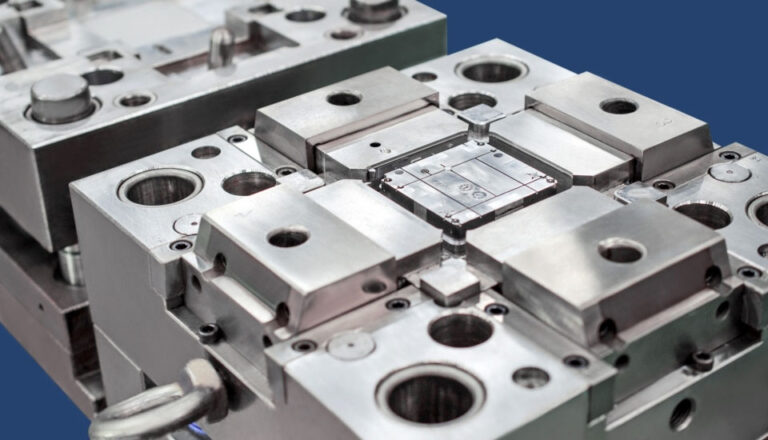

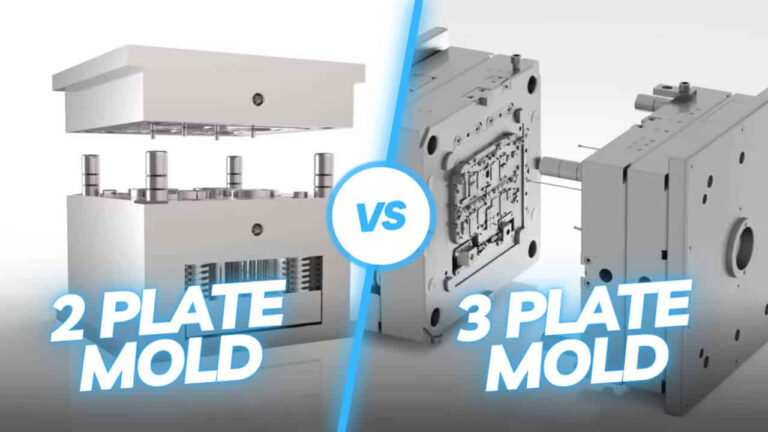

3, Difficulty of mold: Grade A Grade B Grade C Grade D

① Grade A: Moulds with complex structures such as multiple slides, multiple partings with inclined tops, core pulling and rotary core pulling.

② Grade B: The mold structure is more complex, with multiple (two to four) rows of inclined ejectors, two to three partings, and core extraction.

③ Grade C: Simple pinpoint gate injection mold with one or two slides, inclined top and other general structures.

④ Grade D: Moulds with large sprue, two-plate moulds, moulds with simple structures such as no slides and no inclined tops.

4, Mould size: Extra large, large, medium and small

Extra large: mold width is over 800mm.

Large: Molds with a width between 600 and 800 mm (excluding 800).

Medium: Molds with a width between 350 and 600 (excluding 600).

Small: Molds with a mold width of less than 350.