Generally speaking, contact seals have good sealing performance, but are limited by friction and wear, and are suitable for occasions with low sealing surface linear speeds. Non-contact seals have poor sealing performance and are suitable for occasions with higher speeds.

1, Silicone rubber

Silicone rubber has outstanding resistance to high and low temperatures, ozone, and weathering. It maintains its unique elasticity, ozone resistance, and weathering resistance within an operating temperature range of -70 to 260°C. It is suitable for making sealing gaskets required in thermal mechanisms, such as sealing bushings for strong light source lampshades and valve gaskets. However, due to its lack of oil resistance, low mechanical strength, and high price, silicone rubber is not suitable for making oil-resistant sealing products.

2, Nitrile rubber

Nitrile rubber has excellent resistance to fuel oil and aromatic solvents, but is not resistant to media such as ketones, esters and hydrogen chloride. Therefore, oil-resistant sealing products are mainly made of nitrile rubber.

3, Neoprene

Neoprene has excellent oil and solvent resistance. It also has good resistance to gear oil and transformer oil, but is not resistant to aromatic oils. Neoprene also has excellent resistance to weathering and ozone aging. Neoprene’s crosslinking breaking temperature is above 200°C, and it is commonly used to make door and window seals.

Neoprene also has good corrosion resistance to inorganic acids. In addition, because neoprene also has good flexibility and airtightness, it can be made into diaphragms and vacuum sealing products.

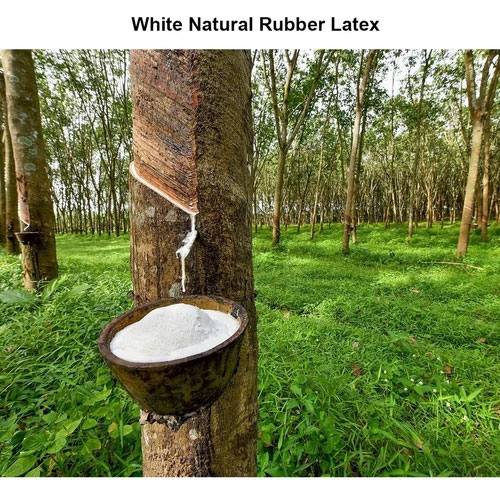

4, Natural rubber

Compared with most synthetic rubbers, natural rubber has good comprehensive mechanical properties, cold resistance, high resilience and wear resistance. Natural rubber is not resistant to mineral oils, but is relatively stable in vegetable oils and alcohols.

In the hydraulic brake system where the brake fluid is a mixture of n-butanol and refined castor oil, the rubber bowls and rubber rings used as seals are made of natural rubber, and general sealants are also often made of natural rubber.

5, Fluororubber

Fluororubber has outstanding heat resistance (200-250°C) and oil resistance. It can be used to manufacture cylinder liner seals, rubber bowls and rotating lip seals, which can significantly increase the service life.

6, EPDM

The main chain of EPDM is a fully saturated linear structure without double bonds. Its side chains contain diene groups, which allows it to be vulcanized with sulfur. EPDM has excellent resistance to aging, ozone, weathering, heat (it can be used for a long time in an environment of 120°C), and chemical resistance (such as alcohols, acids, strong bases, and oxidants), but it is not resistant to corrosion by aliphatic and aromatic solvents.

EPDM has the lowest density among rubbers and possesses high filling properties, but lacks self-adhesion and inter-adhesion properties. Furthermore, EPDM exhibits outstanding steam resistance, making it suitable for use in sealing products such as steam-resistant diaphragms. EPDM is widely used in washing machines, television accessories, door and window seals, and in the production of rubber strips for various composite cross-sections.

7, Polyurethane rubber

Polyurethane rubber has excellent abrasion resistance and good air impermeability, and its operating temperature range is generally -20 to 80°C. It also has moderate resistance to oil, oxygen, and ozone aging, but is not resistant to acids, alkalis, water, steam, or ketones. It is suitable for manufacturing various rubber sealing products, such as oil seals, O-rings, and diaphragms.

8, Chlorochloroether rubber

Epichlorohydrin rubber combines the advantages of nitrile rubber, chloroprene rubber, and acrylic rubber. It is resistant to oil, heat, ozone, flame, alkali, water, and organic solvents, and has good processing properties. However, its cold resistance is relatively poor. As long as the operating temperature is not too low, epichlorohydrin rubber is still an excellent material for manufacturing sealing products such as oil seals, various sealing rings, gaskets, diaphragms, and dust covers.

9, Acrylic rubber

Acrylic rubber is resistant to hot oils (mineral oil, lubricating oil, and fuel oil), especially at high temperatures, typically up to 175°C. It can withstand temperatures up to 200°C for intermittent use or short periods. However, its disadvantage is poor cold resistance. Therefore, it is suitable for making seals resistant to high-temperature oils in non-cold regions, but unsuitable for sealing products subject to tensile or compressive stress at high temperatures.