Introduction

Turning is a machining method that creates a desired shape by removing material, and is classified as cutting. Turning processes can achieve complex shapes by combining various tools and machining methods. The following sections will introduce its characteristics and machining steps.

What is CNC turning?

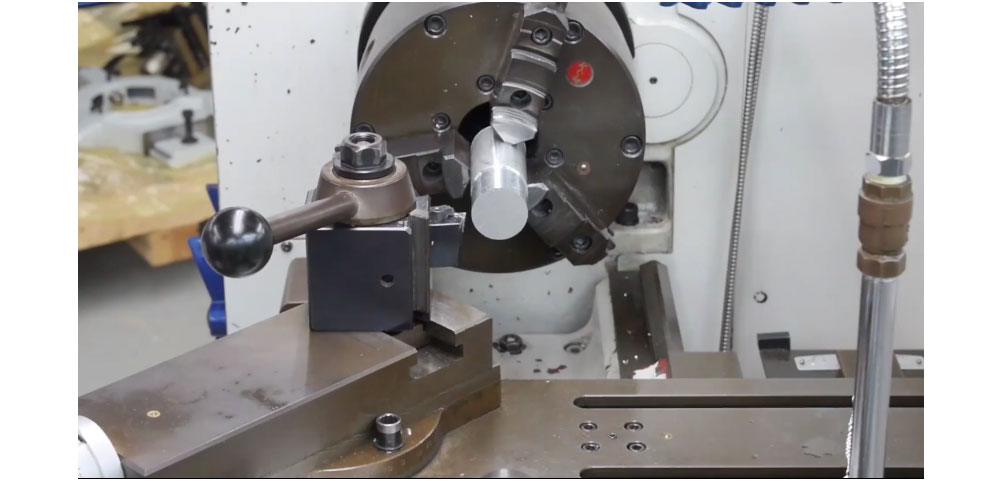

CNC Turning is a type of cutting process. Cutting processes also include milling and drilling. Turning involves inserting a tool into a rotating material to form the desired shape by removing unwanted parts.

CNC Turning is very similar to milling, which is also a cutting process, but the difference lies in what is being rotated. Turning rotates the workpiece, while milling holds the workpiece stationary while the tool rotates to complete the process.

Basic processing methods of lathe

CNC Turning includes eight basic machining methods: facing, outer diameter machining, chamfering, inner diameter machining, threading, drilling, cutting off, and knurling. Each method is described below.

1,End face processing

During machining, the workpiece is slightly longer than the desired finished part length. Facing is a machining operation used to machine the end of a workpiece perpendicular to the axis of rotation. During turning, the tool moves along the radius of the workpiece, removing a thin layer of material to produce the desired part length and a smooth surface.

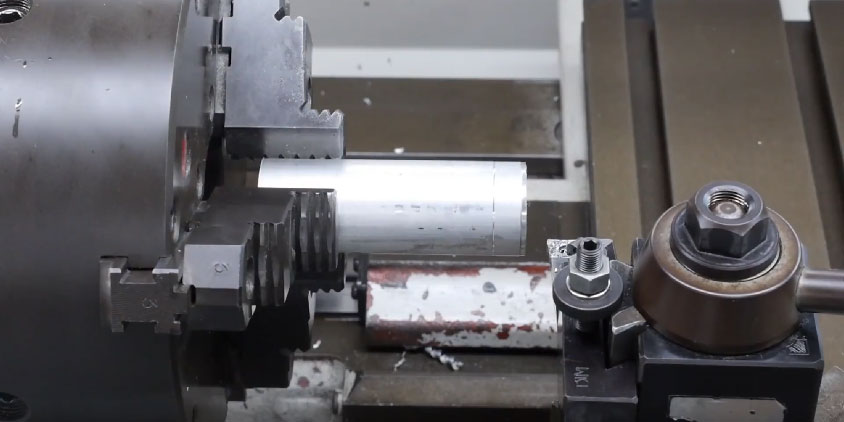

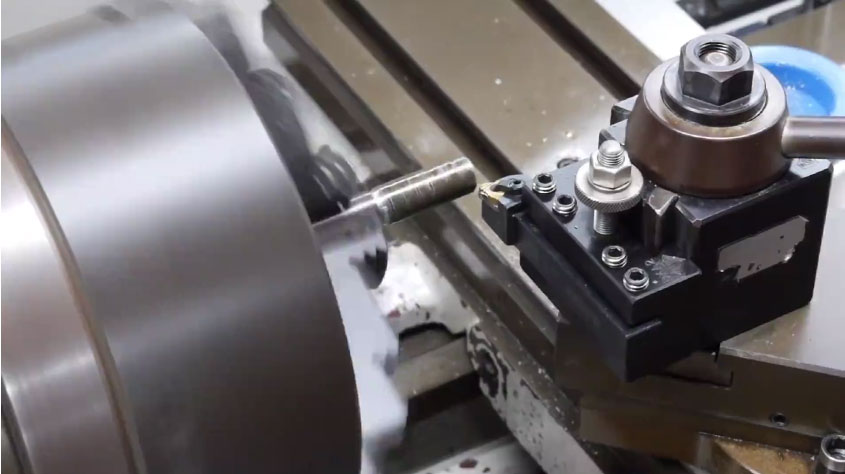

2,Outer diameter processing

OD machining involves placing the cutting tool against the outside of the rotating material. This is the most common machining method used in turning, and is used to finish surfaces or to create a rough outline of the target shape during the initial machining phase.

During outer diameter machining, the generated chips may become entangled with the tool. Especially in finishing machining that requires high precision, the tool angle must be adjusted to prevent chip entanglement and deterioration of precision.

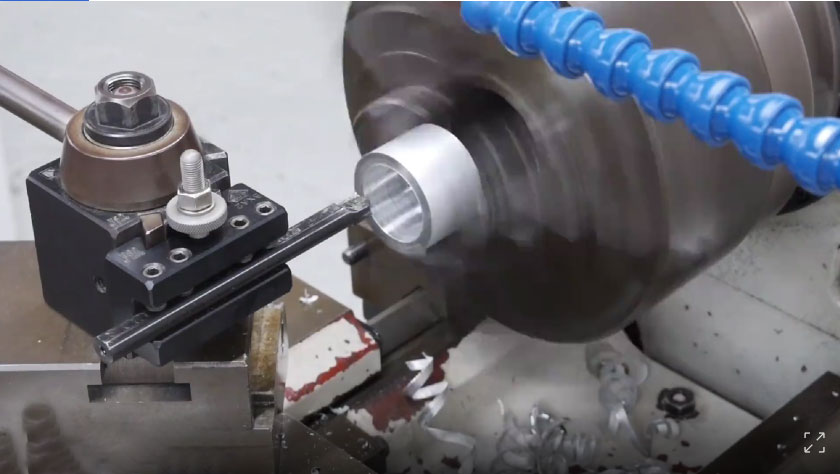

3, Chamfering

On a lathe, you can use a special chamfering tool and select different tool angles and sizes according to your needs to perform turning processing.

Chamfering is the process of turning a bevel, usually at a 45-degree angle, on the edge of a workpiece or the inner or outer edge of a hole to remove burrs and sharp angles and improve the safety, assembly and aesthetics of the workpiece.

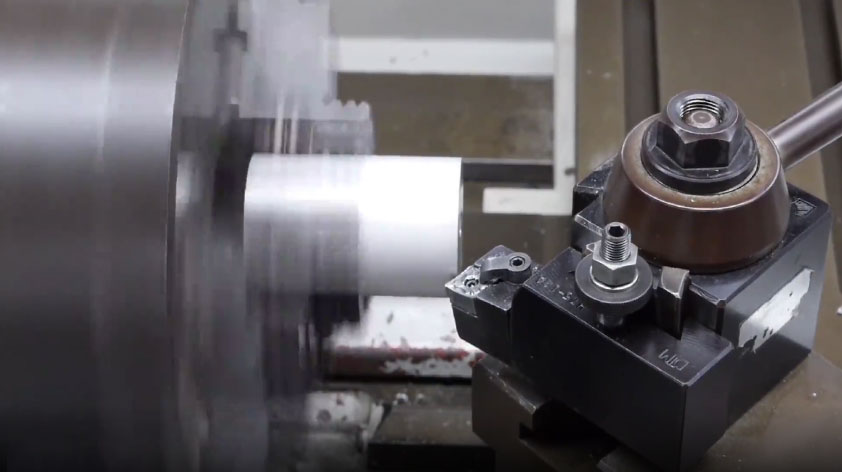

4,Inner diameter machining

Internal diameter machining is the process of enlarging a hole created by drilling or other processes by cutting the inside of the material. This can be used to adjust the size of a hole and finish the inner surface.

In internal diameter machining, the tool length must be increased according to the depth of the hole being machined. However, it is important to note that excessively long tools are prone to bending, resulting in reduced accuracy. Furthermore, chips will remain in the hole, requiring frequent chip removal.

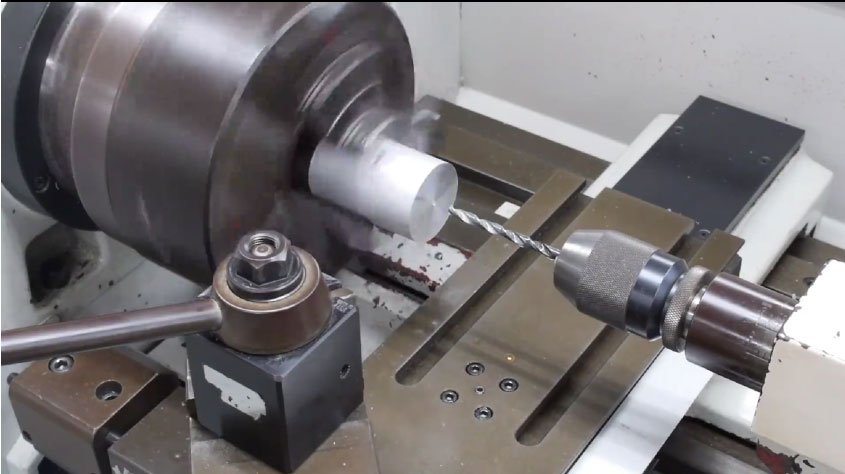

5,Drilling

Drilling is a process where a drill bit is pressed against a rotating material to create a hole. This is particularly true when drilling an internal diameter (ID) part, where a hole must be drilled to allow access to a specialized tool.

Since the drilling accuracy of the drill bit is not very high, after drilling the hole of the necessary size, the subsequent finishing is usually done by internal diameter processing.

6,thread turning

Threading is a machining process used to create screw threads. Using specialized thread turning tools, turning can produce both internal and external threads. While milling and machining centers are typically only capable of producing internal threads, one of the main advantages of turning is its ability to produce external threads.

A dedicated threading tool is placed on the workpiece and moved at a constant speed. To ensure the thread pitch remains evenly spaced, the “auto-feed function” is often used to maintain a constant speed.

7,Cutting

Parting off is a machining method that presses a tool against the material to remove the unwanted portion, such as circular cutting of a cylinder.

8,Knurling

Lathe knurling is a process that uses a knurling tool on a lathe to create a specific texture on the surface of a workpiece. This process is primarily used to increase friction or enhance the aesthetics of the workpiece surface. Knurling patterns typically come in two types: straight and crosshatch, with varying coarseness and fineness depending on the application.

Advantages and disadvantages of CNC turning

● Advantages

Turning can produce round products. Another important advantage is that high dimensional accuracy can be achieved because the material is rotated while being cut.

The rotation speed and rotation method can be changed arbitrarily. In addition, there are many types and lineups of tools depending on the application. By combining them with the processing method, products with complex shapes can be produced.

● Disadvantages

Although turning can achieve complex shapes by combining various tools and machining methods, the more frequently the tools are changed, the longer it takes to produce a product.

In addition, in order to fully utilize a variety of processing methods, skilled operators are required, so not everyone can produce high-precision products. The appropriate processing method needs to be selected based on the complexity of the product and the technical level of the operator.

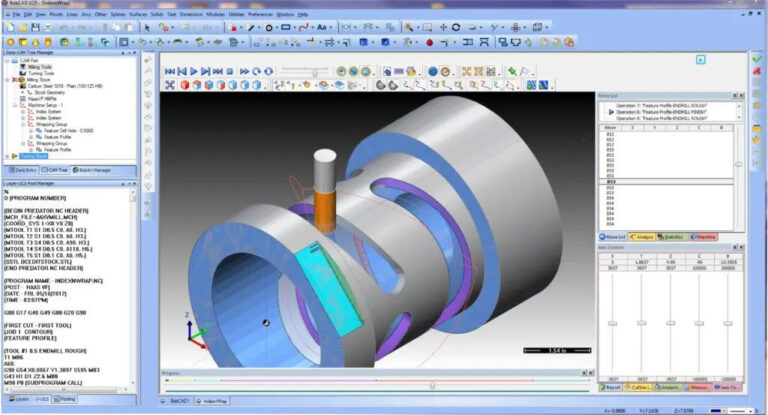

CNC Turning steps

The turning steps vary slightly depending on the product being manufactured. Only the typical general steps are described here.

- Install tools and materials

First, install the cutting tool and material for turning. They must be securely installed to prevent loosening during machining. Any deviation from the installed position will result in reduced accuracy, so high-precision positioning is essential.

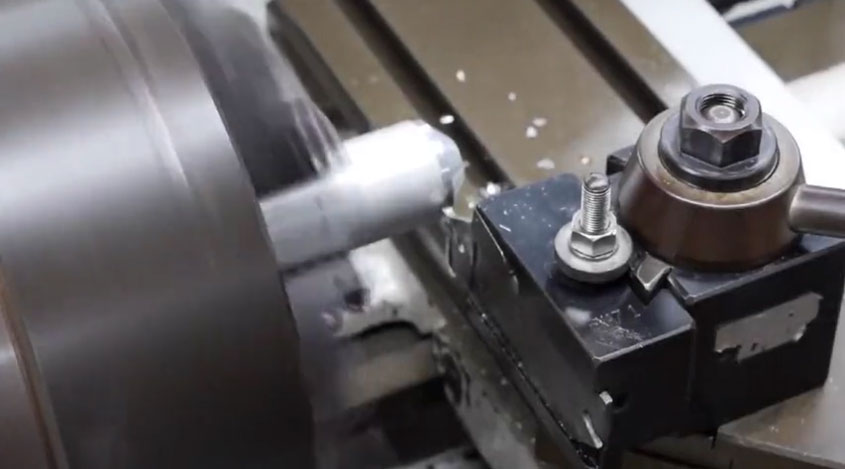

- Rough machining

Next, rough machining is performed, lathing out the rough shape of the desired product. While this process doesn’t require high precision, care must be taken to avoid excessive lathing. Furthermore, attention must be paid to the material’s rotational state and the generation of chips.

- Finishing

After rough turning creates the general shape of the product, finishing is performed. Because high precision is required, the rotational speed and feed rate must be carefully monitored during finishing. If burrs are present, they must be carefully removed with a file without damaging the machined surface.

Precautions for CNC turning parts

When turning components, the required precision needs to be achieved at the lowest possible cost.

When designing parts, the focus is on reducing the amount of material required to be removed and shortening machining time. In addition, ensuring that products can be machined using commonly available tools without the need for special tools is used to shorten delivery times and reduce costs.

When performing turning operations, it is important to determine the machining sequence and select tools in such a way that the steps are as minimally complicated as possible.

Summary

Turning is a type of cutting process in which a cutting tool is applied to a rotating material. Lathes can perform operations such as outer and inner diameter machining, threading, drilling, and cutting. Lathes are generally classified into various types, including general-purpose lathes, NC lathes, tabletop lathes, front-end lathes, and vertical lathes, and each type is used according to its intended purpose.