Concept of Two-Color Injection Molding

Two-shot molding (2K molding or two color molding) refers to the process of molding two plastics (or two plastics of different colors) into one piece during a single injection molding process.

In this article, the first injected material is referred to as the base material and the second injected material is referred to as the cover material.

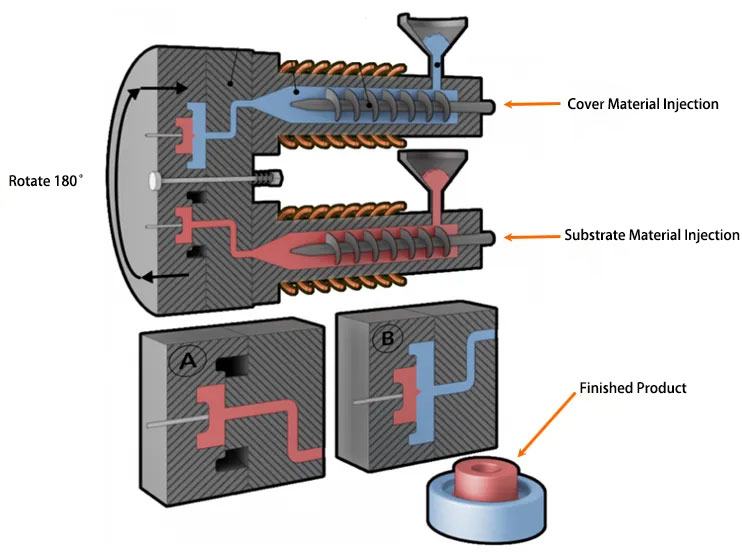

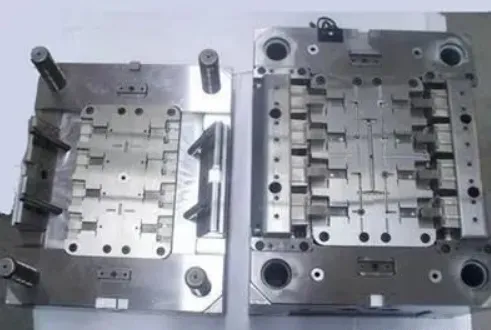

The most common form of two-color injection mold is that two identical movable molds correspond to two different fixed mold cavities.

After the first injection of the base material, the mold is opened first, and then the movable mold is rotated 180 degrees using the rotatable structure of the injection machine, and then the mold is closed and the second injection is performed using a different color material or a different material (covering material) than the first injection.

After the second mold opening, the punch that has completed two injections is demoulded.

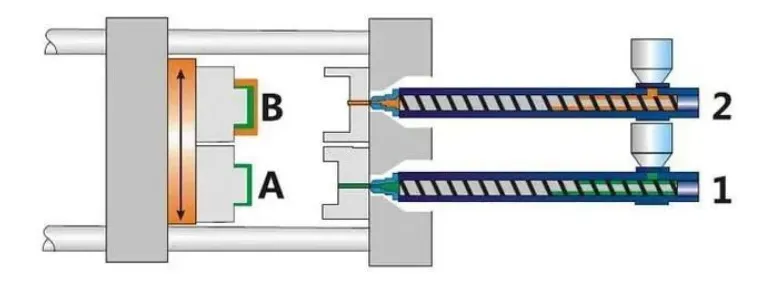

The first injection of the base material and the second injection of the covering material are carried out simultaneously, requiring the injection machine to have two injection nozzles to inject different colors or different base materials and covering materials respectively.

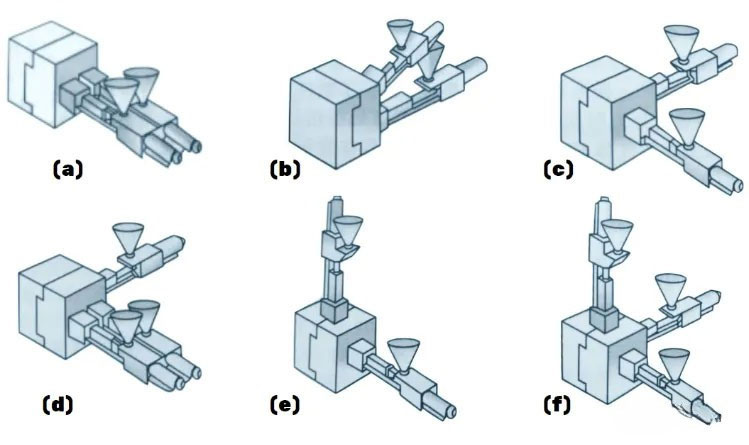

The schematic diagram of two-color and multi-color injection molding machines is shown in the figure.

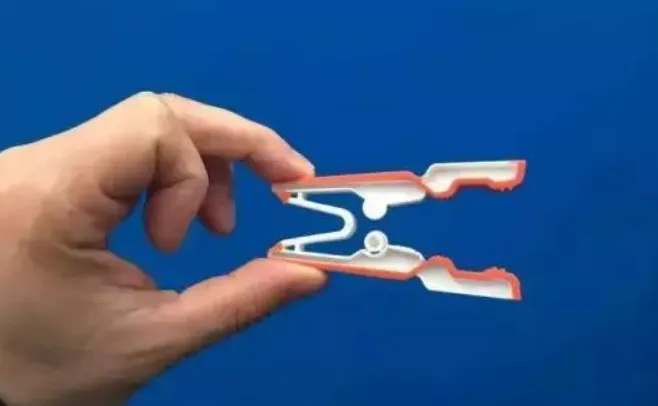

The most typical example of two-color injection molding in daily production is toothbrush.

A toothbrush is a product that combines hard and soft plastics. The main body of the toothbrush is made of hard plastic to provide sufficient strength, while the part that contacts the hand is made of soft plastic to ensure a good touch. At the same time, two-color injection molding can also give the toothbrush a colorful appearance.

Working Principle of Two-shot Injection Molding

Two-shot injection molding requires a male mold and two female molds. The first injection is performed in the male mold and the first female mold. After molding, the mold is opened and the second injection is performed directly in the second female mold without demoulding. After demoulding, the two-color injection molded product is obtained.

In actual production, two sets of male molds are usually used, each set is responsible for one injection, and different female molds are switched by rotating 180° vertically.

Requirements for materials, processes and molds for two-color injection molding

Material requirements

The paired materials for two-color injection molding must meet two basic compatibility conditions, namely bonding compatibility and processing compatibility.

Process requirements

【Soft and hard double shot design】

There must be a certain temperature difference between the melting points of the two materials. 60°C is generally recommended, and at least 30°C is recommended. The melting point of the first shot material is higher. Generally, the first shot is PC or PC/ABS, and the second shot is TPU or TPE. The thickness of PC is 0.6-0.7mm, and the thickness of soft is 0.4mm or more.

Try to widen the contact area, make grooves to increase adhesion, or use core pulling for the first shot, and inject part of the material of the second shot into the first shot. Make the surface of the first shot mold as rough as possible.

【Transparent and non-transparent double shot design】

Double-shot design for small lenses : the first shot is for non-transparent, the second shot is for lenses. Try to use PC with a high melting point for the first shot, and PMMA for the second shot.

A double-shot design with both transparent and non-transparent materials for decoration: The first shot is for the non-transparent material, and the second shot is for the transparent material. Polycarbonate (PC), a high-temperature material, is often used for the non-transparent material, while PMMA or PC is used for the transparent material. PC requires UV protection, while PMMA can be UV- or hardened. UV protection is essential if the surface has text.

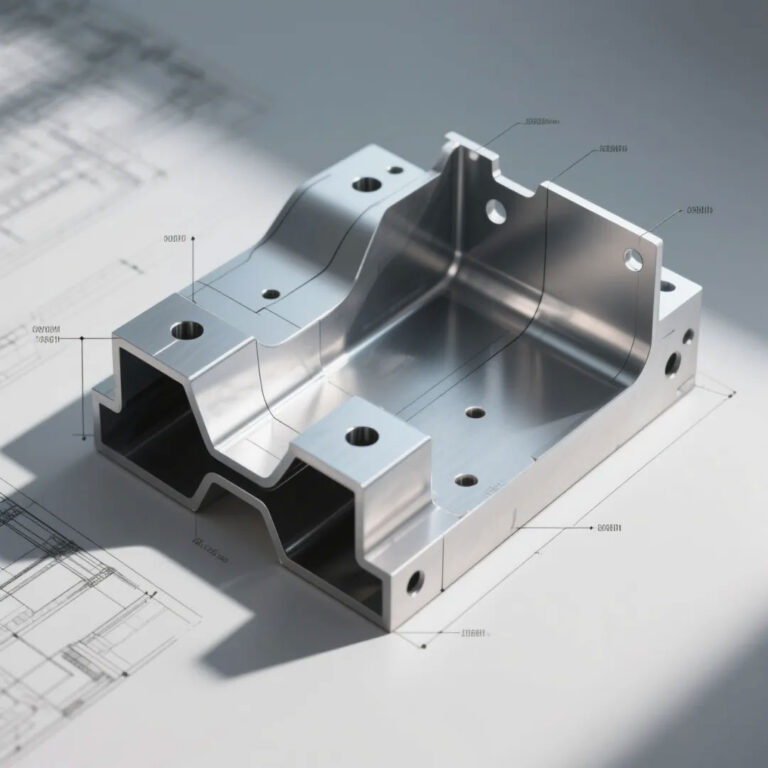

Requirements for mold

- The two shapes of the female mold must be different, each molding a product, while the two shapes of the male mold must be exactly the same;

- The front and rear molds of the mold must match after rotating 180 degrees around the center;

- Carefully check the maximum mold thickness, minimum mold thickness, KO hole distance, etc.

- The nozzle of the three-plate mold should be designed to have automatic demoulding action;

- When designing the second injection mold, in order to prevent the second mold from scratching the glue position of the first molded product, a part of the gap can be designed. However, the strength of each glue sealing position must be carefully considered;

- During injection molding, the size of the product molded in the first injection molding can be slightly larger so that it can be pressed more tightly against the other male mold during the second molding to achieve the effect of sealing;

- Pay attention to whether the flow of plastic will impact the product that has been molded for the first time during the second injection molding, causing its glue position to deform;

- Before closing the A and B plates, pay attention to whether the front mold slider or inclined top will reset first and crush the product;

- The water supply arrangement of the two female molds and the male mold should be as sufficient and balanced as possible;

- In 99% of cases, the hard plastic part of the product is injected first, and then the soft plastic part of the product, because the soft plastic is easy to deform.

The Difference Between Secondary Injection Molding And Two-Shot Injection Molding

Here we need to explain the difference between secondary injection molding and two-color injection molding.

Double injection molding involves first creating a single-color plastic part on a single-color injection molding machine, then manually placing it into a second mold for injection molding. This process does not require a dedicated injection molding machine. Two-shot injection molding involves two injections, all done within the machine. This process is typically done on a dedicated two-color injection molding machine.

The difference between two-shot injection molding and insert injection molding

The difference between two-shot injection molding and insert injection molding (or overmolding) is:

1) Insert molding uses a common injection molding machine. After the product is removed from one mold, it is placed in another mold for a second injection molding.

Therefore, insert injection molding is usually completed by two sets of molds, without the need for a dedicated two-color injection molding machine.

Two-shot injection molding is the process of simultaneously injecting two plastics at one time using a dedicated two-color injection molding machine.

Two plastics are injected on the same injection molding machine, forming the parts twice, but the product is only ejected once. Therefore, two-color injection molding is usually completed with one set of molds and requires a dedicated two-color injection molding machine.

2) During the entire process of two-color injection molding, the plastic is in a molten state and there is no cooling shrinkage, which means that there is an opportunity to form a strong chemical link between the base material and the covering material, which has high strength and reduces the risk of burrs.

3) Compared with insert molding, two-color injection molding does not require the insert placement process, the molding cycle is shorter, more efficient, and the quality is higher.

Advantages of two-color injection molding

1) Increase product design flexibility

Two-shot injection molding can integrate multiple functions into one plastic part, such as soft-touch surface, ergonomic design, two-color appearance, brand logo, feature improvement, noise reduction, shock absorption, waterproof and collision protection, etc., which can save design space and reduce the number of parts.

2) Reduce the number of projects to reduce costs

A single injection molding process can produce multifunctional plastic parts, reducing secondary processing.

3) Different plastics are integrated into one through chemical links, which has higher quality and better strength.

Disadvantages or limitations of two-color injection molding

1) The compatibility between the two plastics needs to be considered

Because different plastics have different chemical properties, their compatibility will directly affect the bonding strength and bonding effect of the bonding surface. Not all plastics have good compatibility with each other.

2) The shrinkage difference of plastics should be small

Too large a difference will affect the bonding strength of the joint surface and may cause warping of the product.

3) The shape of the finished product should not be too complicated

Material selection for two-color injection molding

Different plastics have different chemical properties, and their compatibility will directly affect the bonding strength and bonding effect of two-color injection molding.

Therefore, when designing two-color injection molding products , the most important thing is to choose the most suitable base material and covering material.

1) Select substrate materials and covering materials with good compatibility.

When selecting a specific material type, it is best to contact the plastic supplier for more professional advice.

Different TPE models from RTP Company, although all belong to the TPE series, have significant differences in compatibility with plastics (X indicates good compatibility) .

| Rigid Substrate Material | RTP 2700 S | RTP 2740 S | Permaprene™ 2800 B | Nylabond™ 6091 & 6092 | Polabond® 6042 | Polabond® 6041 |

|---|---|---|---|---|---|---|

| ABS | X | X | ||||

| PA 6 | X | |||||

| PA 6/6 | X | |||||

| PC | X | X | ||||

| PC/ABS | X | X | ||||

| PBT/PC | X | X | ||||

| PET/PC | X | X | ||||

| PC/PMMA | X | X | ||||

| PP | X | X | X | |||

| RTPU | X | Design for Cost Reduction |

2) The difference in melting temperature between the base material and the covering material should not exceed 30-60 °. The melting temperatures of common plastics are shown in the figure below:

| Plastic | Melting Temperature (°C/°F) |

|---|---|

| Min. | |

| ABS | 200/392 |

| PA 12 | 230/446 |

| PA 6 | 230/446 |

| PA 66 | 260/500 |

| PBT | 220/428 |

| PC | 260/500 |

| PC/ABS | 230/446 |

| PC/PBT | 250/482 |

| HDPE | 180/356 |

| LDPE | 180/356 |

| PEI | 340/644 |

| PET | 265/509 |

| PETG | 220/428 |

| PMMA | 240/464 |

| POM | 180/356 |

| PP | 200/392 |

| PPE/PPO | 240/464 |

| PS | 180/356 |

| PVC | 160/320 |

| SAN | 200/392 |

3) The coefficient of thermal expansion (CTE) of the substrate material and the covering material should be as close as possible.

4) The shrinkage rates of the substrate material and the covering material should be as close as possible.

5) Avoid combining amorphous plastics with semi-crystalline plastics.

6) The HDT of the substrate material should be higher;

Main Applications

The two-color injection molding process is now widely used in almost all plastic fields such as automobiles, electronic products, power tools, medical products, home appliances, toys, etc.

Let’s showcase two-color process products from several fields.

Two-shot injection molding can directly produce products with multiple colors at one time, such as toys, stationery, etc.