Introduction

Before injection molding with a new mold, or when changing to another mold for production, trial molding is an essential step. The success or failure of the trial molding directly affects the smoothness of subsequent production in the factory. Therefore, during the trial molding process, it is necessary to follow reasonable operating procedures and record useful technical parameters to facilitate mass production of the product.

Precautions before trial molding

1, Understand the relevant information about molds. Ideally, you should obtain the mold design drawings, analyze them in detail, and invite a mold technician to participate in the trial molding process.

2, Check its mechanical movements on the workbench. Check for scratches, missing parts, and looseness; ensure the mold slide moves smoothly; check for leaks in water channels and air pipe joints; and indicate any limitations on the mold’s opening stroke. Performing these checks before installing the mold can prevent wasted time and effort by discovering problems during installation and then disassembling the mold.

3, Once it is confirmed that the operation of each part of the mold is appropriate, a suitable trial injection molding machine should be selected. When selecting a machine, the following should be noted:

(1) What is the maximum injection volume of the injection molding machine?

(2) Whether the inner distance of the tie rod can accommodate the mold;

(3) Does the maximum travel distance of the activity template meet the requirements?

(4) Whether other relevant trial mold tools and accessories are fully prepared. Once everything is confirmed to be in order, the next step is to hoist the mold. When hoisting, it is important to note that the hooks should not be removed until all clamping templates are locked and the mold is opened, to prevent the clamping templates from loosening or breaking and causing the mold to fall.

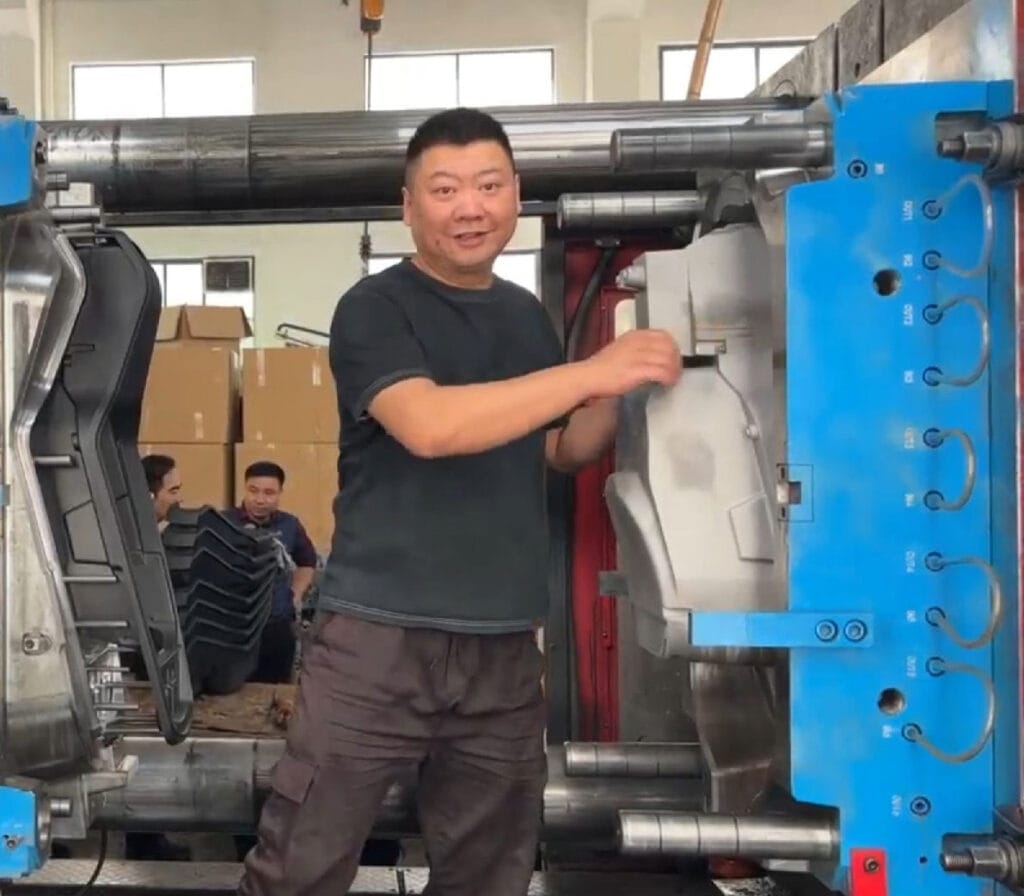

After the mold is installed, the mechanical movements of each part of the mold should be carefully checked, such as whether the sliding plate, ejector pin, ejector mechanism and limiting switch are working properly, and whether the injection nozzle and the feed port are aligned. The next step is to pay attention to the mold closing action.

At this time, the mold closing pressure should be reduced. During manual and low-speed mold closing, pay attention to whether there are any irregularities or abnormal noises. The process of hoisting the mold is actually relatively simple. The main point that requires careful attention is that aligning the mold gate and nozzle is more difficult. Usually, test strips can be used to align the center.

4, Increase mold temperature Based on the properties of the raw materials used in the product and the size of the mold, select an appropriate mold temperature controller to raise the mold temperature to the required temperature for production. After the mold temperature is raised, the operation of each part must be checked again, because the steel may cause mold jamming due to thermal expansion. Therefore, attention must be paid to the sliding of each part to avoid tearing and vibration.

5, If the factory does not implement experimental planning principles, it is recommended that when adjusting trial molding conditions, only one condition should be adjusted at a time in order to distinguish the impact of a single condition change on the product.

6, Depending on the raw materials, the raw materials used should be roasted appropriately.

7, Use the same raw materials as much as possible for trial molding and future mass production.

8, Do not use substandard materials for mold testing. If there are color requirements, color testing can be arranged at the same time.

9, Issues such as internal stress often affect secondary processing. Secondary processing of the mold should only begin after the trial molding has been completed and the product has stabilized. After slowly closing the mold, the clamping pressure should be adjusted, and the operation repeated several times to check for uneven clamping pressure, in order to prevent burrs on the product and deformation of the mold.

After checking all the above steps, lower the mold closing speed and pressure, and set the safety latch and ejection stroke. Then adjust to normal mold closing speed and pressure. If a maximum stroke limit switch is involved, the mold opening stroke should be shortened slightly, and the high-speed mold opening action should be cut off before the maximum mold opening stroke. This is because during mold assembly, the high-speed action stroke is longer than the low-speed stroke during the entire mold opening stroke. On plastic injection molding machines, the mechanical ejector rod must also be set to operate after the full-speed mold opening action to prevent the ejector plate or release plate from deforming due to stress.

Before making the first injection, please check the following items again:

examine

(1) Whether the feeding process is too long or too short;

(2) Is the pressure too high or too low?

(3) Is the mold filling speed too fast or too slow?

(4) Whether the processing cycle is too long or too short.

To prevent short shots, breakage, deformation, burrs, or even damage to the mold, the molding process must be completed. If the cycle time is too short, ejector pins may pierce the mold or the ejector ring may damage it, potentially causing the mold to take two or three hours to remove. If the cycle time is too long, weak points in the mold core may break due to shrinkage of the molded material. Of course, you cannot anticipate all possible problems that may occur during trial molding, but thorough preparation and timely action will help you avoid serious and costly losses.

Main Steps of Trial Molding

To avoid unnecessary waste of time and trouble during mass production, it is indeed necessary to patiently adjust and control various processing conditions, find the best temperature and pressure conditions, and develop standard trial molding procedures, which will help establish daily work methods.

- Check whether the plastic in the barrel is correct and whether it has been baked according to regulations (if different raw materials are used for trial molding and production, different results may be obtained).

- Thorough cleaning of the feed tube is essential to prevent inferior or contaminated material from entering the mold. Inferior or contaminated material can cause the mold to jam. Check that the feed tube temperature and mold temperature are suitable for the raw material being processed.

- Adjust the pressure and injection volume to produce products with a satisfactory appearance. However, avoid burrs, especially when some molded parts have not yet fully solidified. Think carefully before adjusting various control conditions, as even slight changes in the filling rate can cause significant changes in the filling process.

- Be patient and wait for the machine and mold conditions to stabilize; even for medium-sized machines, this may take more than 30 minutes. Use this time to check for potential problems with the products.

- The screw advance time should not be less than the solidification time of the gate plastic; otherwise, the weight of the product will decrease, thus impairing its performance. Furthermore, when the mold is heated, the screw advance time should be appropriately increased to ensure proper compaction of the product.

- Make reasonable adjustments to reduce the total processing cycle.

- Run the newly adjusted conditions for at least 30 minutes until they stabilize, and then produce at least a dozen full mold samples continuously. Mark the date and quantity on the containers and place them according to the mold cavity to test the stability of the operation and derive reasonable control tolerances (especially valuable for multi-cavity molds).

- Measure and record the important dimensions of the continuous samples (measurements should be taken after the samples have cooled to room temperature).

- Compare the dimensions measured for each sample, noting the following: (1) Whether the product dimensions are stable; (2) Whether there is a trend of increasing or decreasing in certain dimensions, indicating that the machine processing conditions are still changing, such as poor temperature control or hydraulic pressure control; (3) Whether the dimensional variation is within the tolerance range.

- If the product dimensions no longer change and the processing conditions are normal, observe whether the quality of the products from each mold cavity is acceptable and whether their dimensions are within the allowable tolerances. Record the mold cavity numbers that are consecutively larger or smaller than the average value to check whether the mold dimensions are correct.

Record the parameters obtained during the trial molding process

Record and analyze the data to inform modifications to molds and production conditions, and to serve as a reference for future mass production.

- Allow the processing time to be longer to stabilize the melt temperature and hydraulic oil temperature.

- Adjust the machine conditions according to whether the size of all products is too large or too small. If the shrinkage rate is too large and the product appears to be under-filled, you can also refer to increasing the gate size.

- Correct any excessive or insufficient dimensions of the mold cavities. If the dimensions of the mold cavities and gates are correct, then try changing the machine conditions, such as the filling rate, mold temperature, and pressure of each part, and check whether some mold cavities are filling too slowly.

- Make individual corrections based on the fit of each mold cavity product or the displacement of the mold core. It may be necessary to further adjust the filling rate and mold temperature to improve its uniformity.

- Inspect and repair any faults in the injection molding machine, such as malfunctions in the oil pump, oil valve, temperature controller, etc. These can cause changes in processing conditions, and even the most perfect mold cannot achieve good working efficiency on a poorly maintained machine. After reviewing all recorded values, retain one set of samples for comparison to check whether the corrected samples have improved. Properly preserve all records of sample inspections during trial molding, including various pressures during the processing cycle, melt and mold temperatures, barrel temperature, injection timing, screw feeding time, etc. In short, preserve all data that will help establish the same processing conditions in the future to obtain products that meet quality standards.

Final Thought

Currently, mold temperature is often overlooked during factory trial molding. However, mold temperature is the most difficult to control during short-term trial molding and future mass production. Incorrect mold temperature can affect the size, gloss, shrinkage, flow marks, and material shortage of the sample. If a mold temperature controller is not used to control it, difficulties may arise during future mass production.