Introduction

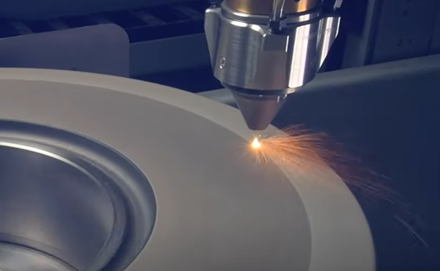

Laser cladding technology refers to a process in which selected coating materials are placed on the surface of the coated substrate in the form of different fillers. A thin layer of the substrate surface is melted simultaneously by laser irradiation and rapidly solidified to form a surface coating with extremely low dilution and metallurgical bonding with the substrate material, thereby significantly improving the wear resistance, corrosion resistance, heat resistance, oxidation resistance and electrical properties of the substrate surface.

Laser cladding classification

According to the material type of laser cladding and the coupling form between the material and the laser beam, common laser cladding technologies can be divided into coaxial powder feeding laser cladding technology, side-axis powder feeding laser cladding technology (also called lateral powder feeding laser cladding technology), high-speed laser cladding technology (also called ultra-high-speed laser cladding technology) and high-speed wire laser cladding technology.

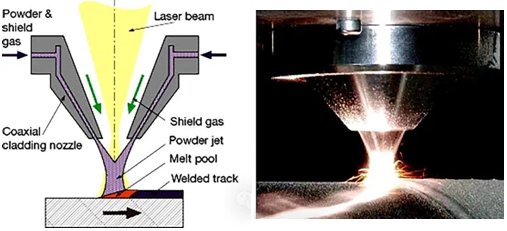

01 Coaxial powder feeding laser cladding technology

Coaxial powder-feed laser cladding technology typically utilizes a semiconductor fiber laser and a disc-type gas-borne powder feeder. The cladding head utilizes a circular beam pattern with a central beam output. Powder is fed in a circular pattern or multiple beams around the beam, and a dedicated shielding gas channel is provided. The powder beam, beam, and shielding gas flow intersect at a single point. During cladding, a molten pool forms at this focal point. As the cladding head and workpiece move relative to each other, a coating forms on the workpiece surface.

Technical features of coaxial powder feeding laser cladding:

- High degree of freedom and ease of automation. Since the cladding layer can be obtained in any direction during cladding, there are no restrictions on its cladding direction. When used with industrial robots or multi-axis motion machine tools, it can clad the surface of parts along any path or in any shape. When used as a 3D printing print head, it can perform laser coaxial powder feeding 3D printing.

- The molten pool has good inert gas protection effect. A special inert gas flow channel is set on the cladding head, and the molten pool is in a good local inert gas atmosphere during the cladding process.

- Small molten pool, uniform powder heating, and excellent crack resistance of the cladding layer. The spot size of coaxial powder feeding laser cladding is generally ∮1-∮5mm. The powder and beam are in uniform contact, and the heat transfer during the cladding process is more uniform, resulting in excellent crack resistance of the cladding layer.

02 Paraxial Powder Feeding Laser Cladding Technology

Paraxial laser cladding, also known as lateral powder feeding, typically utilizes a semiconductor direct-output laser or semiconductor fiber-output laser and a gravity powder feeder. The cladding head utilizes a rectangular beam spot coupled with paraxial broadband powder feeding. When the cladding head is operating, alloy powder is delivered to the workpiece surface through a powder feed nozzle for pre-positioning. As the cladding head and workpiece move relative to each other, a rectangular laser beam scans the pre-positioned alloy powder, melting it to form a molten pool. Upon cooling, the cladding layer forms.

Technical features of paraxial powder feeding laser cladding:

- High material utilization rate. By pre-depositing powder on the workpiece surface and then scanning and irradiating the workpiece with a laser beam to melt it, the material utilization rate can reach over 95%, saving a lot of material costs.

- High cladding efficiency. The parallel-axis powder feeding laser cladding technology adopts a rectangular spot solution. While ensuring that the energy density of the spot in the cladding direction remains unchanged, the laser power and spot width can be increased, significantly improving the cladding efficiency.

- No inert gas consumption. Side-axis powder feeding laser cladding technology generally uses a gravity powder feeder, which does not require the consumption of inert gas. Therefore, it has certain requirements on the oxidation resistance of the powder material, which limits its application areas.

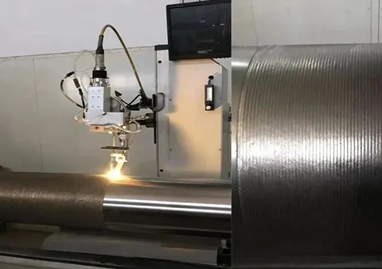

03 Ultra-high-speed laser cladding technology

Ultra-high-speed laser cladding technology utilizes semiconductor fiber lasers or fiber lasers with superior beam quality, a precisely designed high-speed laser cladding head, and a high-speed or fast-moving motion mechanism. The laser beam is precisely coupled with the powder beam and inert gas flow. During operation, a portion of the laser energy is used to heat the powder beam, while the remaining portion of the laser beam, which penetrates the powder beam, heats the substrate. The powder is melted or heated to a very high temperature before entering the molten pool, shortening the time required for powder melting and achieving very high cladding line speeds (up to 200 m/min, compared to 2 m/min for conventional laser cladding).

Ultra-high-speed laser cladding technology features:

- High laser energy utilization efficiency. The laser beam of ultra-high-speed laser cladding technology passes through the powder beam to illuminate the molten pool, with most of the laser energy acting on the powder and workpiece, reducing reflection and scattering losses of the laser. This significantly improves the laser energy utilization efficiency to around 65%.

- High cladding efficiency. Ultra-high-speed laser cladding technology has high laser energy utilization, very high cladding line speed and thin cladding layer, which can achieve very high cladding efficiency (cladding efficiency can reach more than 0.7m2/).

- Low dilution rate of the cladding layer. Ultra-high-speed laser cladding technology has a high cladding line speed and a short molten pool existence time, so the dilution rate of the cladding layer is very low.

- The cladding layer has good roughness, good crack resistance and small deformation of the workpiece.

04 High-speed wire laser cladding technology

High-speed wire laser cladding technology utilizes a semiconductor fiber laser, a high-precision wire feeding system, and a precision cladding head to perform laser cladding on a metal wire. During operation, the wire is fed sideways into the laser beam, which melts the wire to form a molten pool. The cladding layer forms as the cladding head and workpiece move relative to each other.

High-speed wire laser cladding technology features:

- Environmentally friendly. High-speed wire laser cladding technology uses metal wire instead of traditional metal powder. The rigid wire completely melts to form the cladding layer. There is no splashing or metal dust during the cladding process, making it more environmentally friendly than traditional powder laser cladding.

- High material utilization rate. Through the precise design of the cladding head and metal wire, the metal wire will be completely melted, and the melting process is very gentle and spatter-free, making high-speed wire laser cladding have a very high material utilization rate (up to 99%).

- High cladding efficiency. High-speed wire laser cladding technology uses a special composite energy source to achieve a semi-molten state before the metal enters the molten pool. Only a small amount of energy and a very short time are required to completely melt and form a molten pool. Therefore, the cladding efficiency of high-speed wire laser cladding is higher than that of traditional powder laser cladding.

- Low heat input, low line energy, and minimal workpiece deformation. The high-speed wire laser cladding process achieves line energy as low as 0.29 kJ/cm by precisely controlling energy input and maintaining a high cladding line speed, significantly reducing workpiece deformation caused by heat input.

- The cladding layer is dense, with low dilution rate and low defect rate.

Influence of process parameters on cladding effect

The main process parameters of laser cladding include laser power, spot diameter, cladding speed, defocusing amount, powder feeding speed, scanning speed, preheating temperature, etc. These parameters have a great influence on the dilution rate, cracks, surface roughness and density of the cladding layer. An inappropriate set of process parameters will lead to poor metallurgical bonding between the cladding layer and the substrate, which is not conducive to the formation of multi-layer channels. There are three important process parameters for laser cladding:

1.Laser power

The melted volume of the substrate is primarily determined by the laser power. Increasing laser power leads to a rapid increase in the melted volume of the substrate. The greater the laser power, the more cladding metal is melted, and the greater the probability of pores. As laser power increases, the depth of the cladding layer increases, the surrounding liquid metal fluctuates violently, and dynamic solidification and crystallization occur, gradually reducing or even eliminating pores and cracks. If the laser power is too low, only the surface coating melts, leaving the substrate unmelted. This can lead to localized pilling and voids on the cladding surface, failing to achieve the desired surface cladding effect.

2.Spot diameter

The laser beam is generally circular, and the width of the cladding layer is primarily determined by the laser beam spot diameter. As the spot diameter increases, the cladding layer becomes wider. Generally speaking, a small spot size produces good cladding quality, while increasing the spot size results in decreased cladding quality. However, a spot diameter that is too small is not conducive to achieving a large cladding area.

3.Cladding speed

Cladding speed has a similar effect to laser power. If the cladding speed is too high, the alloy powder cannot be completely melted, resulting in poor cladding quality. If the cladding speed is too low, the molten pool remains in place for too long, causing overburning of the powder and loss of alloying elements. Simultaneously, the heat input to the substrate is high, increasing deformation.

The process parameters have an important role in determining the shape and surface quality of the cladding layer. They will affect the bonding between the cladding layer and the substrate as well as the cooling rate. Precise control of the process parameters can effectively achieve the purpose and requirements of laser cladding technology.

Characteristics of laser cladding surface forming technology

- Fast cooling speed and rapid solidification;

- Small thermal deformation, low coating dilution rate, good metallurgical bonding between coating and substrate, and high yield rate;

- A wide range of coating materials are available, such as iron-based, nickel-based, copper-based, titanium-based, etc.

- The coating thickness is generally 0.2mm~2mm, suitable for repairing worn parts;

- High processing precision, capable of processing small or difficult-to-process areas;

- The process is easy to automate.

Laser cladding material system

In addition to the laser cladding parameters, the selection of appropriate coating materials is also important for obtaining laser cladding coatings with the required properties and surface quality. Generally speaking, the physical and chemical properties of the substrate and coating materials should be considered at the same time, and the appropriate coating material should be selected according to the application.

Laser cladding alloy powders can be divided into self-fluxing alloy powders, composite powders, and ceramic powders according to their composition. Among them, self-fluxing alloy powders are the most widely studied and applied in practice.

1.Self-soluble alloy powder

Self-fluxing alloy powders can be divided into iron-based (Fe), nickel-based (Ni), and cobalt-based (Co) alloy powders. Their main characteristics are that they contain boron (B) and silicon (Si), which give them self-deoxidation and slag-forming properties. They also contain relatively high levels of chromium, which preferentially melt with the oxygen in the alloy powder and the oxides on the surface of the workpiece to form low-melting-point borosilicates, which cover the surface of the molten pool and prevent excessive oxidation of the liquid metal. This improves the wettability of the melt to the base metal, reduces the inclusions and oxygen content in the cladding layer, and improves the process forming properties of the cladding layer, resulting in excellent corrosion resistance and oxidation resistance. They have good adaptability to a variety of substrates such as carbon steel, stainless steel, alloy steel, and cast steel, and can obtain cladding layers with low oxide content and low porosity. However, for sulfur-containing steel materials, due to the presence of sulfur, a low-melting-point brittle phase is easily formed at the interface, making the coating easy to peel off, so it should be selected with caution.

(1) Iron-based (Fe) self-fluxing alloy powder

Fe-based alloy materials have the advantages of low cost, good mechanical properties and wide application range. In particular, iron-based alloys of stainless steel system are widely used in laser cladding technology due to their good mechanical properties and excellent corrosion resistance.

In the iron-based alloy powder composition, the hardness of the coating is adjusted by adjusting the alloying element content, and the hardness, crack sensitivity, and retained austenite content of the cladding layer are improved by adding other elements, thereby improving the wear resistance and toughness of the cladding layer. The types of stainless steel coatings currently produced by laser cladding technology mainly include: austenitic stainless steel, martensitic stainless steel, ferritic stainless steel, and duplex stainless steel.

In recent years, research on laser cladding has focused on experiments involving the addition of other components to iron-based powders. The results indicate that the addition of rare earth elements improves the spalling resistance of the passive film on the surface of the cladding layer, reduces the material’s corrosion weight loss to varying degrees, and improves the cladding layer’s corrosion resistance.

(2) Nickel-based (Ni) self-fluxing alloy powder

Ni-based self-fluxing alloy powders are the most widely researched and applied laser cladding materials due to their excellent wettability, corrosion resistance, high-temperature self-lubrication, and reasonable price. Under conditions of severe sliding, impact wear, and abrasive wear, simple self-fluxing alloy powders are no longer sufficient. In these cases, various high-melting-point carbides, nitrides, borides, and oxide ceramic particles can be added to the self-fluxing alloy powder to create a metal composite coating.

Studies have shown that the laser cladding technology is used to prepare Ni-based WC coatings on the surface of Q960E steel. After cladding, the abrasion resistance of the Ni-WC coating is more than 6 times that of the Q960E substrate, effectively utilizing the characteristics of Ni-based powder to achieve the use requirements.

(3) Cobalt-based (Co) self-fluxing alloy powder

Co-based self-fluxing alloy powders offer excellent resistance to heat, corrosion, wear, impact, and high-temperature oxidation. They are often used in industries such as petrochemicals, power generation, and metallurgy for applications requiring high-temperature resistance and corrosion resistance. Common materials used in Co-based alloy powder systems include Co-Ni, Co-Cr-Ni, Cobalt-Iron, and Cobalt-Nickel-Iron. To improve wettability between the coating and the substrate and reduce the oxygen content in the coating, boron and silicon are often added to the powder to create a self-fluxing alloy powder.

Co-based self-fluxing alloys have excellent wettability and a lower melting point than carbides. Upon heating, the Co element first melts and forms a new phase with other elements during solidification, significantly strengthening the cladding layer. Currently, the main alloying elements used in Co-based alloys are nickel, carbon, chromium, and iron. Nickel can reduce the thermal expansion coefficient of the Co-based alloy cladding layer, narrowing the alloy’s melting temperature range, effectively preventing cracks in the cladding layer and improving the cladding alloy’s wettability on the substrate.

The School of Mechanical Engineering at Jiangnan University conducted research on the use of laser cladding technology to prepare cobalt-based/graphene oxide (GO) composite cladding layers on the surface of TC4 titanium alloy. The results showed that the cladding layer mainly contained TiC, Co2Ti, γ-Co, α-Ti and Cr3C2 phases. GO in situ generated TiC with the TC4 matrix at low power, and simultaneously interacted with the semi-solid Co2Ti structure. GO rapidly decomposed at high power, and the cladding layer was mainly composed of Co2Ti structure. When the laser power was P2=1300W, the cladding effect was optimal, the formed structure was uniform, and it was metallurgically bonded to the TC4 matrix. The hardness of the cladding layer was as high as 1100HV0.2, which was almost 2.82 times the hardness of the matrix 390HV0.2.

2.Composite powder

Composite powders primarily refer to powder systems formed by mixing or compounding various high-melting-point hard ceramic materials, such as carbides, nitrides, borides, oxides, and silicides, with metals. Carbide alloy powders and oxide alloy powders have been the most researched and applied, primarily for the preparation of wear-resistant coatings. The carbide particles in the composite powder can be added directly to the laser melt pool or mixed directly with metal powder to form a mixed powder. However, adding them in the form of coated powders (such as nickel-coated carbides or cobalt-coated carbides) is more effective.

3.Ceramic powder

Ceramic powders primarily include silicide and oxide ceramic powders, with oxide ceramic powders (alumina and zirconia) being the predominant types. Zirconia has lower thermal conductivity and better thermal shock resistance than alumina ceramic powder, making it a common choice for thermal barrier coatings. Ceramic powders are often used in the preparation of high-temperature, wear-resistant, and corrosion-resistant coatings due to their excellent wear, corrosion, and high-temperature resistance, as well as their antioxidant properties.

Current research on laser-clad bioceramic materials focuses primarily on hydroxyapatite (HAP), fluorapatite, and Ca- and Pr-containing bioceramics, applied to metal surfaces such as Ti-based alloys and stainless steel. Hydroxyapatite bioceramics, known for their excellent biocompatibility and as a precursor to human teeth, have long garnered widespread attention from researchers both domestically and internationally. Overall, despite a relatively recent start, research on laser-clad bioceramic materials has rapidly developed, representing a promising research direction.

4.Other alloy powders

In addition to the above-mentioned laser cladding powder material systems, currently developed and researched cladding material systems also include copper-based, titanium-based, aluminum-based, magnesium-based, zirconium-based, chromium-based, and intermetallic compound-based materials. Most of these materials utilize the special properties of the alloy system to achieve one or more functions such as wear resistance, friction reduction, corrosion resistance, electrical conductivity, high temperature resistance, and thermal oxidation resistance.

(1) Copper base

Copper-based laser cladding materials primarily include copper-based alloy powders and composite powders, such as Cu-Ni-B-Si, Cu-Ni-Fe-Co-Cr-Si-B, Cu-Al2O3, and Cu-CuO. Exploiting the metallurgical properties of copper alloy systems, such as liquid phase separation, copper-based composite powder materials can be designed for laser cladding of in-situ composite materials. Research has shown that the laser cladding layer contains a large amount of in-situ hard particle reinforcement, resulting in excellent wear resistance. Dan Jiguo et al. utilized the liquid phase separation of Cu and Fe and the metallurgical reaction between the base material and the cladding material to fabricate a copper-based alloy composite cladding layer with a dispersed Fe3Si structure by laser cladding. The study demonstrated that during the laser cladding process, Fe, which enters the molten pool from the base material, forms a liquid phase separation with the Cu alloy in the molten pool. Due to its low density, the Fe entering the molten pool floats upward, where it reacts with Si in the molten pool to form Fe3Si. The Fe3Si is dispersed and gradiently distributed within the α-Cu matrix in the laser cladding layer.

Copper and copper-based alloys are widely used in high-tech fields such as electrical engineering, transportation, aerospace, and manufacturing due to their high thermal and electrical conductivity and comprehensive performance. Copper alloys used in armatures, lead frames, and other applications must not only ensure excellent thermal and electrical conductivity but also possess mechanical qualities, including hardness and resistance to friction and wear, to extend their service life in harsh operating environments. Laser cladding technology creates a dynamic temperature field on the alloy surface, followed by rapid cooling and solidification. Research has shown that under laser cladding technology, the Cu-Cr-SiC system exhibits strong electrical conductivity and mechanical strength, and the addition of SiC ceramic particles can further improve the system’s strength and elastic modulus.

(2) Titanium-based

Titanium-based cladding materials are primarily used to improve the biocompatibility, wear resistance, or corrosion resistance of the base metal surface. The titanium-based laser cladding powder materials studied primarily include pure Ti powder, Ti6Al4V alloy powder, and titanium-based composite powders such as Ti-TiO2, Ti-TiC, Ti-WC, and Ti-Si. Zhang Song et al. laser-clad Ti-TiC composite coatings on Ti6Al4V alloy surfaces in an argon atmosphere. Their study demonstrated the in-situ formation of tiny TiC particles within the composite coating, resulting in excellent friction and wear properties.

Research has found that laser cladding can be used to improve titanium components by depositing defect-free coatings of Ti6Al4V and a Ti6Al4V+TiC mixture. Cladding Ti6Al4V onto a TiGr2 sample increased the substrate hardness from 120 HV to 300 HV. The surface hardness of the Ti6Al4V sample also improved, along with its wear resistance and abrasion resistance. These results suggest that laser cladding technology has potential for repairing and manufacturing titanium mechanical components.

(3) Magnesium-based

Magnesium-based cladding materials are primarily used for laser cladding of magnesium alloy surfaces to improve their wear and corrosion resistance. J. DuttaMajumdar et al. clad a common commercial magnesium alloy with magnesium-based MEZ powder (composition: Zn: 0.5%, Mn: 0.1%, Zr: 0.1%, RE: 2%, Mg: Bal). The results showed that the microhardness of the cladding layer increased from HV 35 to HV 85-100. Furthermore, due to grain refinement and redistribution of intermetallic compounds, the corrosion resistance of the cladding layer in a 3.56wt% NaCl solution was significantly improved compared to that of the base magnesium alloy.

(4) Aluminum base

Laser cladding technology can effectively avoid the problem of cracking caused by excessive heat input during the repair process. Studies have shown that TiC-reinforced Al3Ti composite coatings were prepared on AA6063 aluminum alloy surfaces using laser cladding. The laser-clad layer consists of dendritic Al3Ti, interdendritic α-Al, and uniformly distributed TiC particles, forming a good metallurgical bond between the coating and the substrate. Compared with the substrate, the corrosion resistance of the laser-clad layer was significantly improved, and the corrosion resistance of the cladding layer increased with increasing TiC content. Sorin Ignat et al. used a 3kW Nd:YAG laser with side-feeding to clad aluminum powder onto WE43 and ZE41 magnesium alloy substrates, producing well-bonded cladding layers. The study found that the coatings achieved hardness values ranging from HV 0.05120 to 200, with the increased hardness primarily attributed to the presence of Al3Mg2 and Al12Mg17 metal compounds. ZMei et al. laser clad aluminum-based Al-Zn powder on a magnesium-based ZK60/SiC substrate and obtained a metallurgically good cladding layer.

Conclusion

Laser cladding technology is primarily used for repair and surface enhancement in the aerospace, automotive, petrochemical, metallurgical, and rail transportation sectors. It offers a new method for repairing critical damaged parts, significantly reducing costs and improving efficiency. Using laser cladding to enhance the surface of critical parts can improve their performance and extend their service life. With the increasing maturity of high-power laser technology, reduced manufacturing costs, and in-depth research into its applications in surface engineering and additive manufacturing, laser cladding is poised to become a hot topic in both academia and industry.