Intro

During the manufacturing process, metal parts undergo a series of processing techniques, such as grinding, drilling, milling, turning, tapping, grooving, etc. After processing, it is inevitable that extra protrusions or thorns will be left , which is what we usually call burrs.

Although burrs are small, they directly affect the appearance and use of the product and even cause safety problems, so burrs must be removed.

Deburring is the process of removing excess protrusions or thorns formed on the surface of parts through various methods.

Five types of metal burrs

Depending on the processing method, we can roughly divide burrs into the following five types:

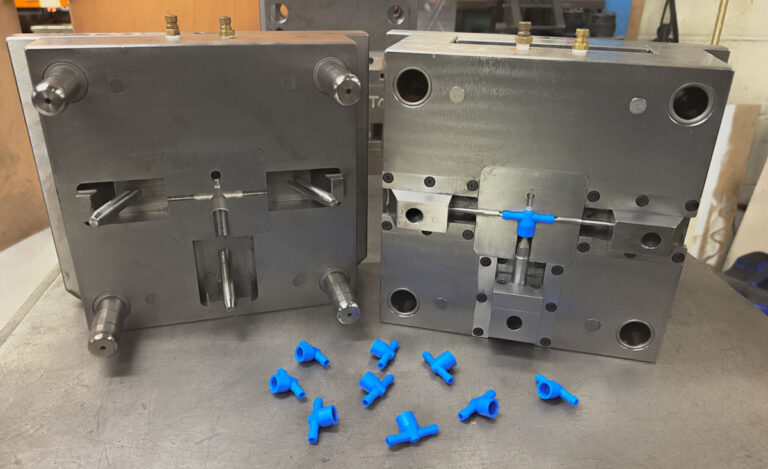

1.Casting burrs

The size of the burr is usually expressed in millimeters, which refers to the excess material produced at the joints of the mold or the root of the gate.

2.Forging burrs

Produced at the joints of the metal die due to plastic deformation of the forging material.

3.Electric welding and gas welding burrs

Electric welding burrs are burrs that protrude from the surface of the part due to the filler at the weld; gas welding burrs are slag that overflows from the incision when the gas is cut off.

4.Stamping burrs

During stamping, burrs are generated due to the gap between the punch and the lower die on the die, or the gap between the tools at the incision, and due to die wear.

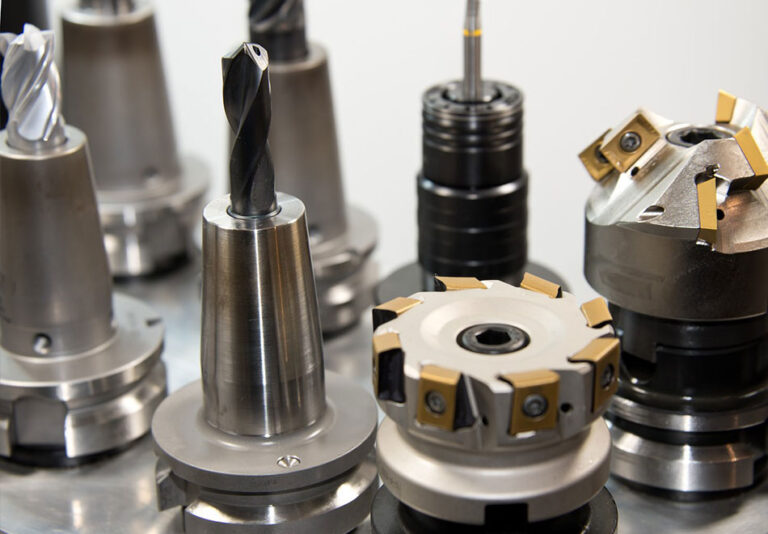

5.Cutting burrs

Burrs can also be produced by machining methods such as turning, milling, planing, grinding, drilling, and reaming. The burrs produced by various machining methods have different shapes depending on the tool and process parameters.

How to remove metal burrs?

With so many burrs, how do you remove them? Choosing the right tools and techniques will make deburring more efficient. Below, Xiao Qi introduces several key deburring techniques.

1. Manual deburring

It refers to the process in which skilled workers use files, sandpaper, grinding heads and other tools to grind and remove burrs.

This method does not require very high technical skills from workers and is suitable for products with small burrs and simple product structures. Therefore, it is also a commonly used method for removing burrs.

2. Grinding and deburring

Grinding deburring is a method of removing burrs through vibration, sandblasting, rollers, etc., and is currently widely used.

The problem with grinding is that it can sometimes not be completely clean, requiring subsequent manual processing or other deburring methods. This method is suitable for small products with large batch sizes.

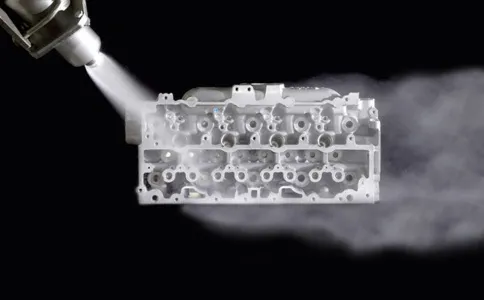

3. High-pressure water jet deburring

Using water as the medium, its instantaneous impact force is used to remove burrs or flash produced after processing, and at the same time, the purpose of cleaning can be achieved.

4. Chemical deburring

By utilizing the electrochemical reaction principle, the burrs on metal workpieces can be automatically and selectively removed.

This method is more commonly used for internal burrs that are difficult to remove, such as fine burrs on valve bodies, pump bodies and other workpieces.

5.Thermal deburring

This process is to fill some flammable gas into a device furnace, and then through the action of some media and conditions, make the gas explode instantly, and use the energy generated by the explosion to dissolve and remove burrs.

Thermal deburring is mainly used in some high-precision parts fields, such as automobile, aerospace and other precision parts.

By understanding these deburring processes and weighing the trade- offs, you can reduce part damage, save time, and money.