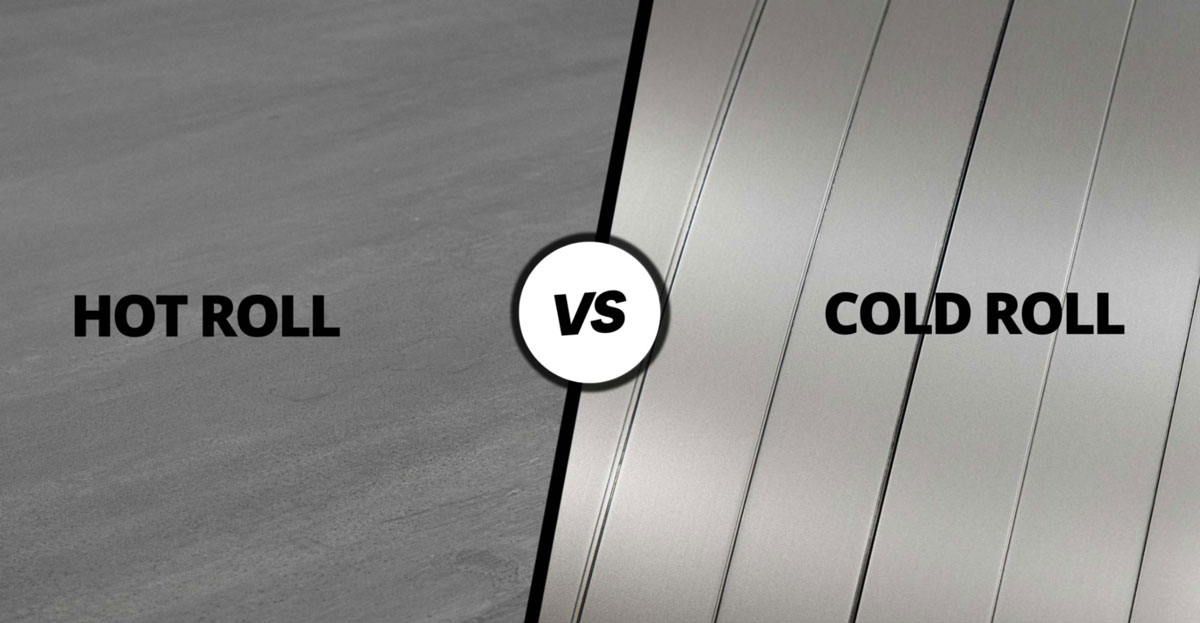

1. Different colors

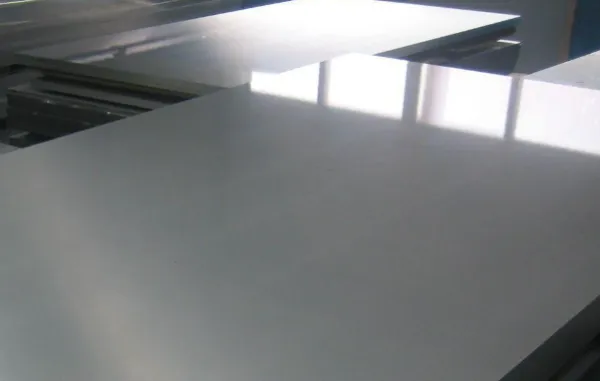

The surface of cold-rolled sheet is oily and silvery white, almost the same as stainless steel.

The surface of the hot-rolled plate is brown, the color is inconsistent, or there are patterns but no oil.

2. Different texture edges

The texture of cold-rolled steel is relatively fine and smooth, with neat edges;

The surface texture of hot-rolled plates is relatively rough, the shape is not as regular as that of cold-rolled plates, and the edges are sometimes uneven.

(The picture below shows hot-rolled plate)

3.Different specifications

Cold rolled steel sheets are generally thin gauges with a thickness of less than 3.0mm (except for customization). Silvery white is galvanized steel sheet, and colored is color-coated steel sheet.

Hot rolled plates are generally over 1.5mm (except customized ones), the thinnest is not less than 1.0, and have temperature-dependent oxidation patterns.

(The picture below shows cold-rolled steel)

4.Different hardness

Cold rolled steel has high hardness and is relatively difficult to process, but it is not easy to deform and has high strength;

Hot rolled steel plates have low hardness, are easy to process and have good ductility.

5.Different production processes

Cold rolling is rolling at room temperature. Cold rolled steel sheets have better strength and the thickness of cold rolled steel sheets is relatively small.

Hot rolled steel plates are rolled at high temperatures, have better ductility, and can be made to a greater thickness.