Punching burrs grow the fastest during stamping , so burr height can be considered to determine the mold maintenance and service cycle. Accordingly, when the die clearance is determined during design, observing the burrs at the punched area can provide a certain degree of insight into the mold’s lifespan. Sharp corners in the die design are more likely to cause chipping, leading to burrs appearing earlier.

As is well known, rounding sharp corners is a common solution to burrs. The order of punch and die materials, from SKS to SKD to powdered high-speed steel to carbide, increases die life. Even when using the same material, better surface roughness of the punch and die can extend die life. This life also varies depending on the lubrication of the materials. If waste material accumulates on the cutting edge, such as chips, the life of the punch and cutting edge will be shortened. Furthermore, the guides of the die frame and the stripper plate (internal guides) can affect die rigidity and dynamic accuracy.

Mold life can be divided into maintenance life (grinding cycle) and total life. The total life can be considered the sum of all previous maintenance lifespans, but depending on the mold structure, it is sometimes difficult to determine the total lifespan.

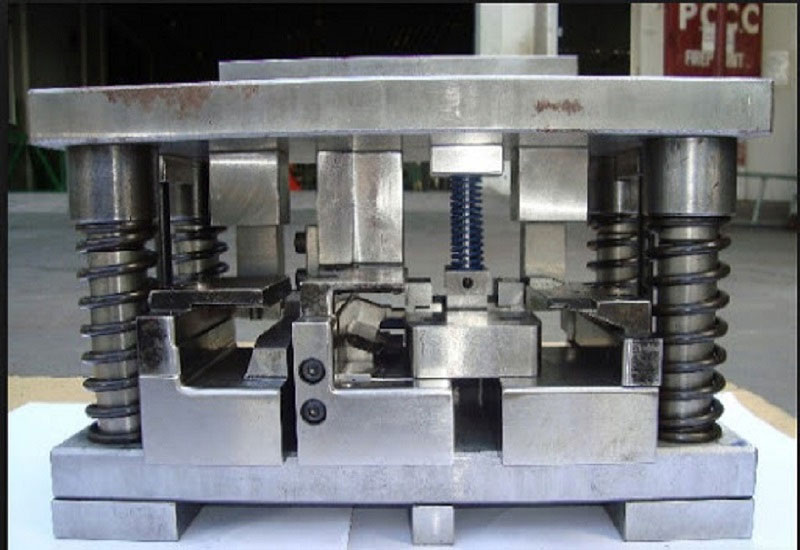

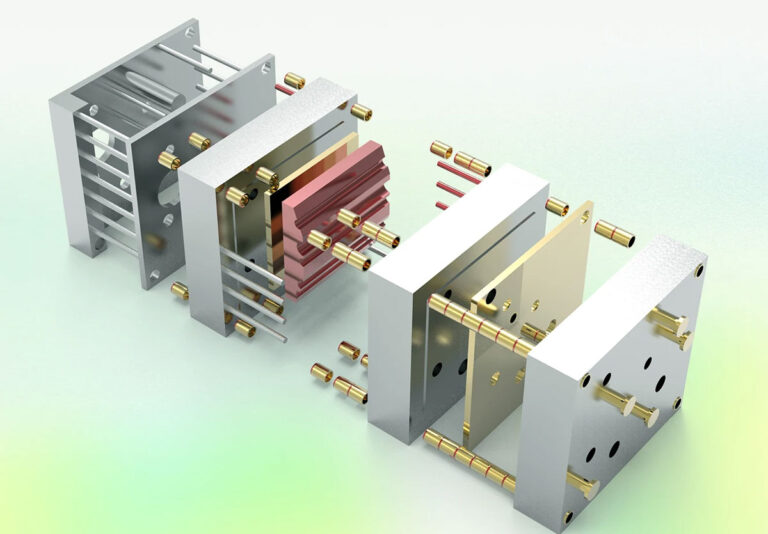

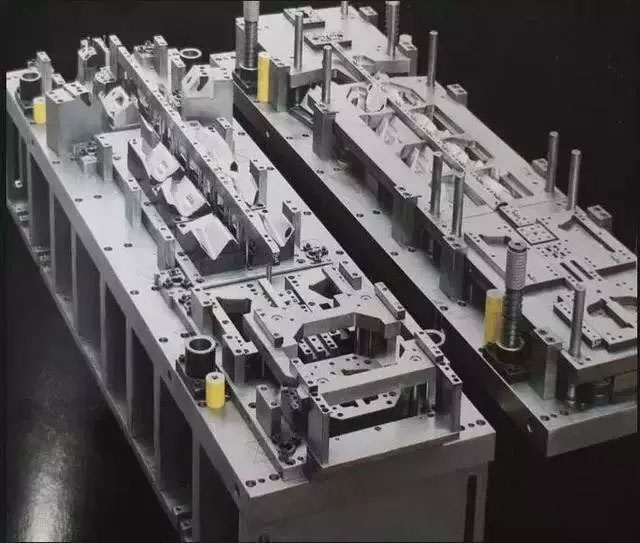

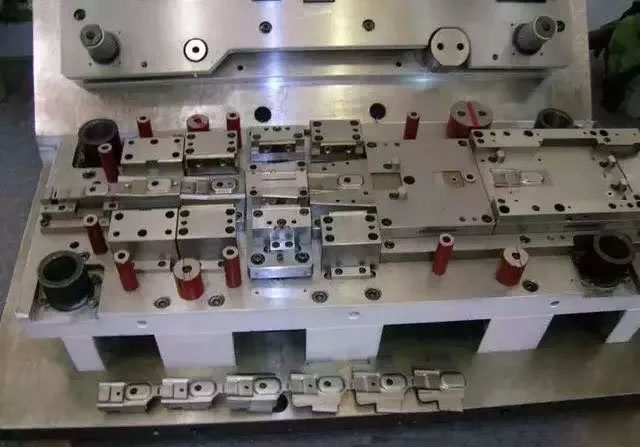

For monolithic molds (rigid frame molds), the plate becomes thinner with each grinding, making it easy to determine the mold’s total lifespan. For inlaid molds, only the inlaid portion needs to be reground and the overall height adjusted for continued use. When a part’s lifespan expires, only the inlaid portion needs to be replaced. Similarly, when internal guides and other components wear, only the worn parts need to be replaced. This repetitive process makes it difficult to achieve the mold’s total lifespan. For such molds, determining their total lifespan requires observing the plate’s condition.

Focus on loosening of insert holes and deformation of the plate surface. When insert holes become loose due to deformation or wear, and the insert’s positioning accuracy can no longer be maintained, it indicates the end of its service life. Regarding plate deformation, each time a stamping operation is performed, although the plate deformation during the stamping process is minimal, the mold plate will still experience slight elastic deformation. This deformation will remain within the plate when the mold is used for a long time. When the plate is in this state, even if new inserts are installed, the original positioning accuracy cannot be maintained. When this maintenance life fails to meet production requirements, it can be determined that the mold has reached the end of its life.

When considering plate life, if you want a longer lifespan, use thicker plates and perform processes such as quenching and cryogenic treatment. If a shorter-life, lower-cost mold is sufficient, use quenched but thinner plates, or install inserts on unquenched plates. The same applies to internal guides. To maximize mold life, use a combination of guide pins and guide bushings. For smaller production runs, directly utilize the holes in the plate as guide pins, eliminating the need for guide bushing machining.

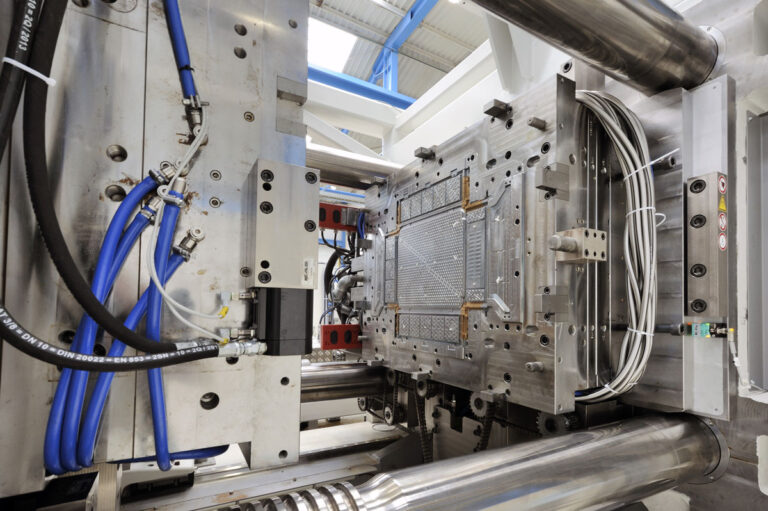

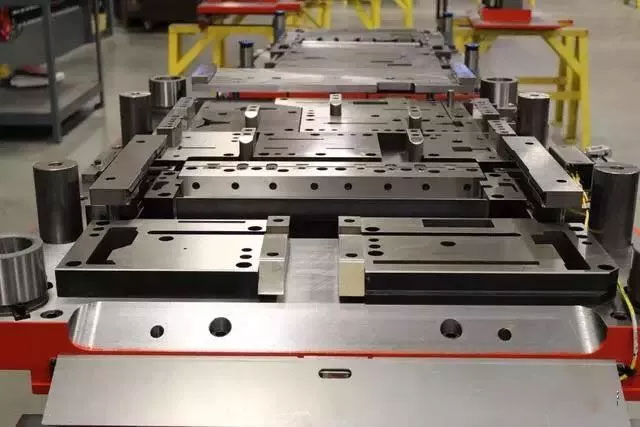

Molds can be categorized into both small-batch and large-scale production molds, with a wide variety of forms and structures. Proper mold manufacturing, ensuring product quality and mold life, is challenging. This is especially true for molds with complex shapes and precision required for low production volumes, which are more challenging due to limited production costs.