Natural disasters that humans cannot resist, dilapidated energy systems, or working environments with safety hazards may interrupt normal production and cause losses to companies and individuals.

To reduce this loss, in addition to maintaining the factory’s power facilities on time, it is also necessary to preventively eliminate safety hazards in the working environment.

For those in the work environment, don’t be afraid to wear protective equipment as required. Also, receive training in relevant professional knowledge, such as basic firefighting and first aid. In short, safety comes first.

The equipment and supporting facilities used must be maintained as required to prevent problems before they occur.

The machine itself also has an automatic detection function, such as power phase loss, motor overheating and other key preventive alarms. For specific handling methods, please refer to the instructions in the operation manual.

After the power is restored, production must continue as usual, and the procedures that were previously forced to be interrupted need to be continued at this time.

Although there are several ways to restore the machine to its previous state, re-edit the program, or load a new program, they are not safe or simple enough.

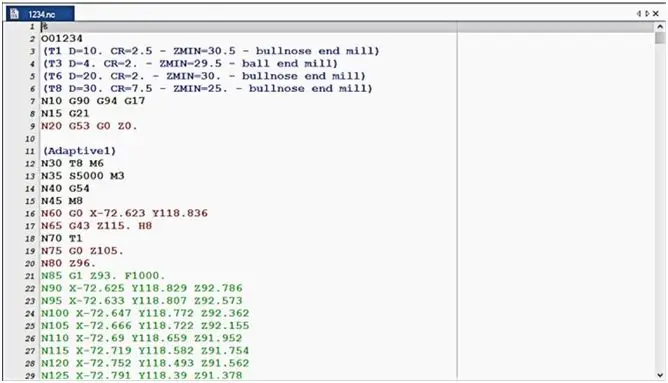

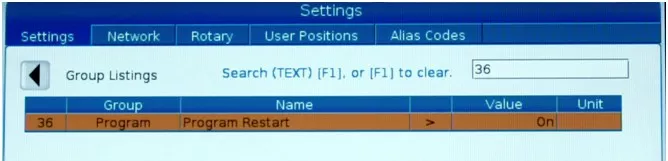

In the Haas CNC system, setting 36 in the setup page can accomplish this task excellently.

First, turn setting 36 (Program Restart) on.

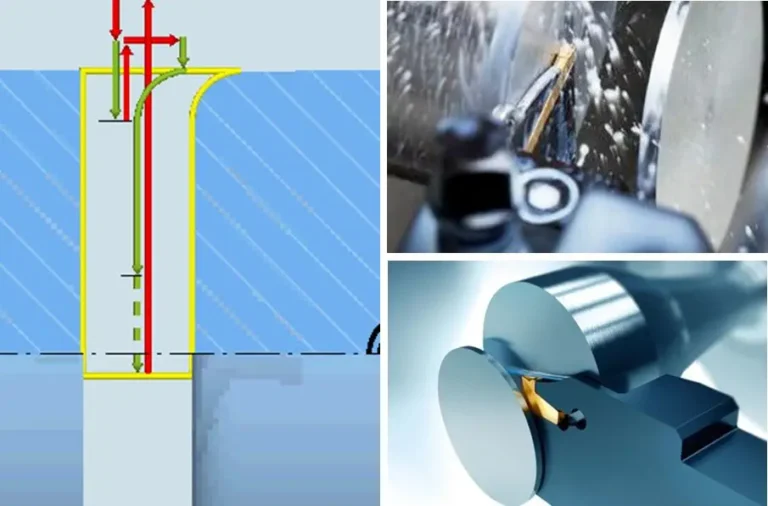

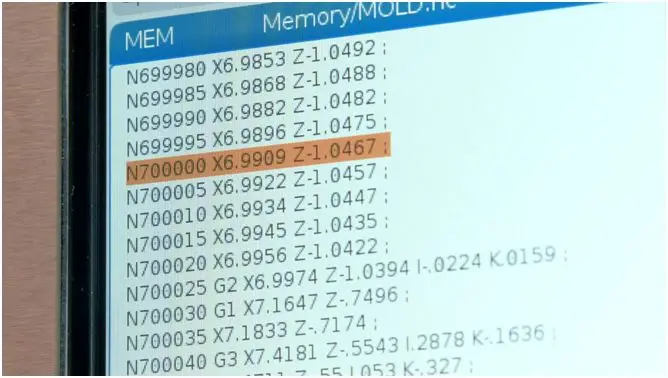

Next, highlight the line you want to restart from.

It may take a short time to scan the previous program and restore the machine to the state before the highlighted line. If the highlighted line is a tool change, the machine may perform a tool change, first changing to the tool used before the highlighted line, and then changing back to the tool used in the highlighted line. This is normal operation, so don’t panic.

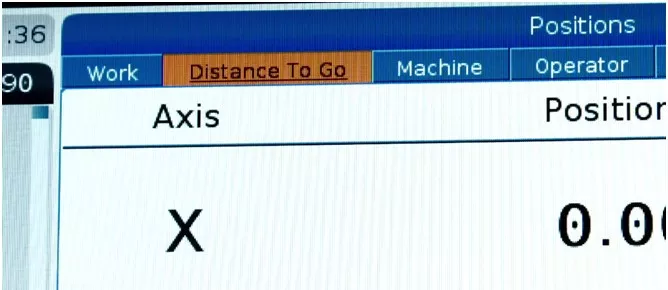

Then, turn on the single-block stop mode and switch the coordinate display on the screen to the moving distance. These two steps are highly recommended. Predicting the machine’s movement trajectory and controlling the machine’s operating status more promptly are crucial for production safety.

Finally, close the door and start processing.

It’s that simple, no need to modify the program or call a new machining program.

You can leave Setting 36 (Program restart) enabled all the time, or only when you’re using it.

The difference between them is: when setting 36 is turned off, the control system will not take the time to scan the previous program, nor will it restore to the state before the highlighted line, so it depends on your actual needs to decide whether it is worth taking the time to restore the machine to the state before the highlighted line.