Wrong speed = tool wear.

Wrong feed rate = noise, burns, scrap.

Recommended feed per tooth

| Tool diameter | Aluminum alloy (mm/tooth) | Steel (mm/tooth) | Stainless steel (mm/tooth) |

|---|---|---|---|

| 3 mm | 0.015–0.03 | 0.01–0.02 | 0.008–0.015 |

| 6 mm | 0.03–0.06 | 0.02–0.035 | 0.015–0.025 |

| 12 mm | 0.06–0.10 | 0.035–0.06 | 0.025–0.045 |

How to calculate cutting data

Example: Tool: 6 mm 2-flute carbide end mill Material: Aluminum Alloy Surface Cutting Speed (SFM): 300 Feed per tooth: 0.05 mm/tooth

1. Speed (RPM): Speed = (300 × 3.82) ÷ 6 = 1910

2. Feed rate: Feed rate = 1910 × 0.05 × 2 = 191 mm/min

Most computer-aided manufacturing (CAM) software will do this calculation automatically – but be sure to verify the results!

Feed speed adjustment for different machining processes

| Process | Adjustment method |

|---|---|

| roughing | Increase feed per tooth and reduce speed |

| finishing | Reduce the feed per tooth and increase the speed |

| Plunge milling | Reduce feed rate by 30–50% (full-tooth cutting) |

| Corner processing | Reduce feed rate or use trochoidal machining path |

| Small knives | Reduce the rotation speed and feed rate at the same time to avoid tool breakage |

End mill geometry and its impact

- Fewer teeth = better chip evacuation (for aluminum)

- More teeth = smoother surface (for finishing)

- The helix angle changes the chip direction and cutting pressure

- Use short tools whenever possible – this increases rigidity

Feed rate and cutting speed by material

| Material | Surface cutting speed (SFM) range | Precautions |

|---|---|---|

| 6061 aluminum alloy | 250–500 | Use 2-3 fluted tools and a small feed per tooth |

| 1018 Steel | 80–150 | Use coated tools and coolant |

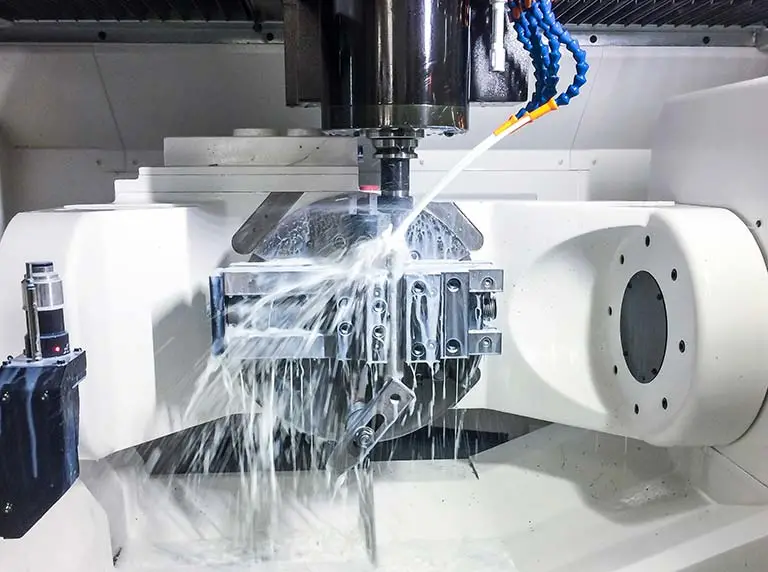

| 304 stainless steel | 60–100 | Use high-pressure coolant and low-speed machining |

| brass | 200–400 | Dry cutting or air cooling, no stickiness |

| titanium alloy | 30–60 | Low surface cutting speed, can use higher feed rate |

| UHMW plastics | 300–800 | Use sharp tools, air-cooled or dry cutting |

Feed rate and cutting speed problem troubleshooting

| symptom | Possible causes | Workaround |

|---|---|---|

| Tool breakage | Feed rate is too high and cutting depth is inappropriate | Reduce cutting depth and check feed per tooth |

| surface burns | Too high speed, no coolant used | Reduce the speed and use spray cooling/flood cooling |

| Flutter | The tool is too long and the feed rate is inappropriate | Use shorter tools and adjust speed |

| Poor surface finish | Tool blunting, feed rate too low | Grind the tool to increase feed rate |

Advanced CNC Feed Rate and Cutting Speed Mastering Techniques

- Refer to the tool manufacturer’s data sheet for ideal parameters

- Initial parameters should be conservative, and the feed rate should be gradually increased based on the effective tool path

- When making deep cuts, try High Efficiency Milling (HEM)

- Stepover should be ≤ 50% of the tool diameter for a smoother surface finish

- Use the feedrate override function of computer-aided manufacturing (CAM) to test actual machining performance