First, You Need to Be an Excellent Process Engineer

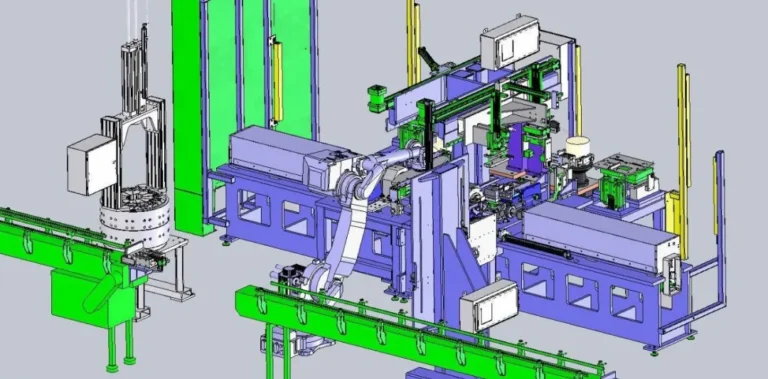

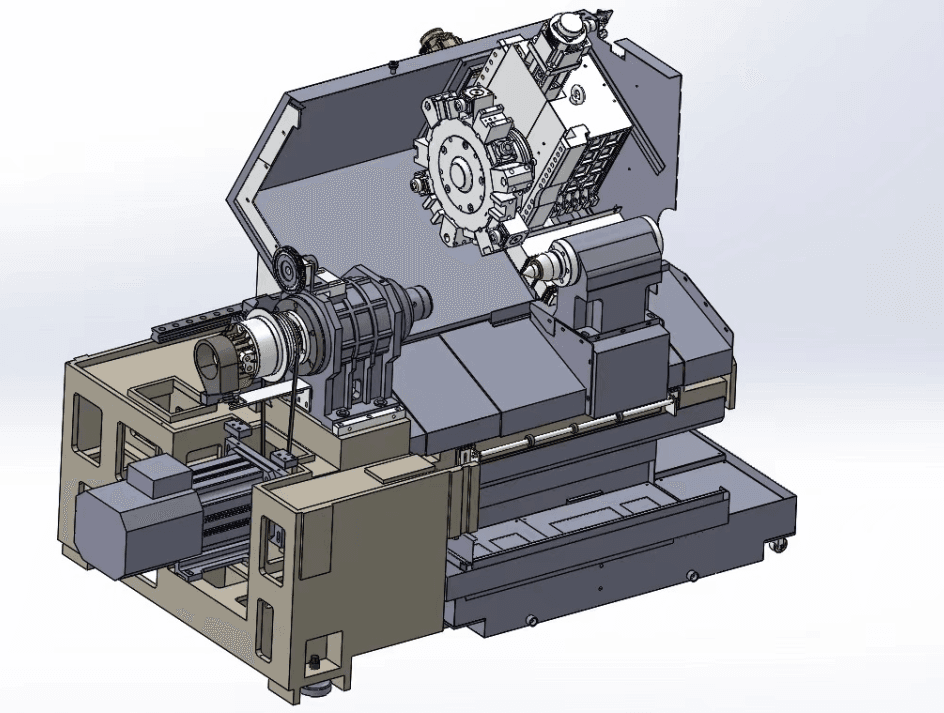

CNC machine tools integrate drilling, milling, boring, reaming, and tapping processes. They require a high level of technical skill from process engineers. CNC programs use computer languages to represent the machining process. Process engineering is the foundation of programming. One cannot claim to be a programmer without understanding the process engineering.

In fact, choosing the profession of machining means that the early stages of the career will be arduous and monotonous. Machining engineers are, to some extent, experienced professionals. Therefore, they must spend time in the workshop, working on lathes, milling machines, grinding machines, machining centers, etc.; and then in the office, they will develop processes, estimate material consumption, and calculate quotas.

You must be familiar with the performance of various machine tools and the skill levels of the workshop workers. After 2-3 years of training, you can basically become a qualified process engineer. You must humbly learn from the experienced workers; their decades of experience can save you a lot of trouble.

This experience cannot be learned from books; process selection is a comprehensive consideration of equipment capabilities and personnel technical abilities. Without the support and trust of your employees, it is impossible to become an excellent process engineer. Through this long period of learning and accumulation, you should reach the following technical levels and requirements:

- Be familiar with the structure and technological characteristics of drilling, milling, boring, grinding, and planing machines.

- Be familiar with the properties of the materials being processed.

- Solid theoretical foundation in cutting tools, and mastery of conventional cutting parameters.

- Be familiar with the company’s process specifications, standards, and general requirements achievable through various processing techniques, including process routes for standard parts, reasonable material consumption, and time quotas.

- Collect a certain amount of information on cutting tools, machine tools, and mechanical standards. In particular, be familiar with the cutting tool systems used in CNC machine tools.

- Be familiar with the selection and maintenance of coolant.

- Have a basic understanding of the relevant trades. For example: casting, electrical discharge machining, heat treatment, etc.

- Has a good foundation in fixtures.

- Understand the assembly and usage requirements of the parts being processed.

- Has a good foundation in measurement technology.

Proficient in CNC programming and computer software applications

There are only a few dozen programming instructions, and they are largely similar across various systems. It generally takes 1-2 months to become very familiar with them. Automated programming software is slightly more complex and requires learning modeling. However, for those with a good CAD foundation, it’s not difficult. Additionally, if you’re programming manually, a good foundation in analytical geometry is also necessary! In practice, the standard for a good program is:

- Easy to understand, well-organized, and easy for any operator to comprehend.

- The fewer instructions in a program segment, the better, aiming for simplicity, practicality, and reliability. From a programming perspective, I believe there are only two main instructions: G00 and G01. The others are auxiliary instructions, set up to facilitate programming.

- Easy to adjust. When the machining accuracy of a part needs to be fine-tuned, it is best not to modify the program. For example, if the tool is worn and needs adjustment, you only need to change the length and radius in the tool offset table.

- Ease of operation. Programming should be based on the operating characteristics of the machine tool, facilitating observation, inspection, measurement, and safety. For example, the same part and the same machining operations will require different programs when processed on a vertical machining center and a horizontal machining center. In machining, the simplest method is the best method. Any experienced professional would surely agree with this statement!

Proficient in operating CNC machine tools

This requires 1-2 years of learning. The operation is all about feel; beginners may understand the steps, but their hands just won’t cooperate. During this process, you’ll learn: systematic operation methods, fixture installation, part datum alignment, tool setting, zero-point offset setting, tool length compensation, radius compensation setting, tool and tool holder loading and unloading, tool sharpening, and part measurement (becoming proficient in using vernier calipers, micrometers, dial indicators, and internal diameter levers). The best tests of operational skill are found in horizontal machining centers and large gantry (moving beam, top beam) machining centers.

Practicing operation requires comprehension! Generally speaking, the entire process, from machining the first part to achieving acceptable machining accuracy, must be completed personally by the CNC programming technician. You won’t pass this stage if you can’t operate the machine tool proficiently.

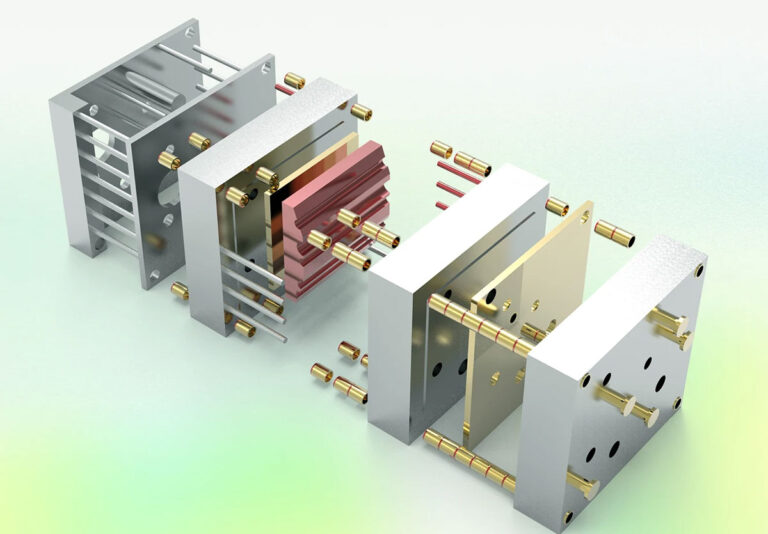

You Must Have Solid Knowledge of Tooling, Fixtures, and Measurement

Tooling, fixtures, and measurement techniques play a role in part machining quality as important as machine tool accuracy and are one of the indicators of a process engineer’s skill level. In the entire process system: machine tool accuracy is guaranteed by the machine tool manufacturer, and cutting tools and parameters are provided by the tool supplier, so generally there are no major issues.

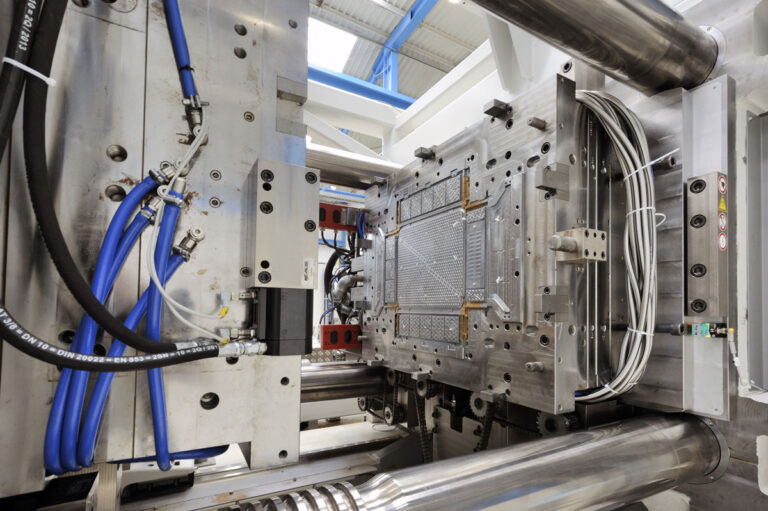

Only tooling and fixtures are specifically designed by process engineers for particular parts. Parts machined on CNC machines are generally quite complex, and therefore, unpredictable problems often arise.

During debugging, more than half of the defects in the first part were caused by unreasonable fixture positioning, clamping points, and clamping force. The difficulty in analyzing fixture-related causes lies in the fact that they can only be qualitatively analyzed, not quantitatively determined. If one lacks experience in fixture design and part clamping, the difficulties become significant.

For learning in this area, it is recommended to consult senior technicians who specialize in precision coordinate boring machines. Accurate measurement skills are one of the fundamental skills in machining; one must be proficient in using vernier calipers, micrometers, dial indicators, internal micrometer levers, calipers, etc. Sometimes, coordinate measuring machines are unreliable for part machining, and manual measurement must be used.

Proficient in the maintenance and upkeep of CNC machine tools

To be familiar with CNC machine tools, one should:

- Familiar with CNC electrical components and control principles. Able to name and explain the function of each component in the electrical box, and able to read electrical schematic diagrams. Able to identify the alarm content based on the electrical alarm number.

- Understand the structure and transmission principle of ball screws. Know which factors have a significant impact on machine tool accuracy.

- Understand the structure of the bearings at both ends of the machine tool lead screw and their impact on the machine tool’s accuracy.

- Understand the machine tool’s lubrication system (bearings, spindle, various moving parts, gearbox, etc.) and be clear about the distribution of each lubrication point. Know the grade of machine tool lubricating oil and the normal weekly or monthly oil consumption.

- Understand the machine tool’s cooling system: cutting (water, air) cooling, spindle cooling, electrical control box cooling, etc.

- Understand the main transmission structure of the machine tool, and the specific data characteristics between the speed and torque of each machine tool.

- Understand the characteristics of machine tool guideways: Is it a linear guide or a slide rail, and what is its rigidity (load-bearing capacity)?

- Able to troubleshoot common operational faults (such as: exceeding limits, incorrect tool number in the tool magazine, etc.).

- Proficient in the various accuracy (static and dynamic) indicators and testing methods of machine tools.

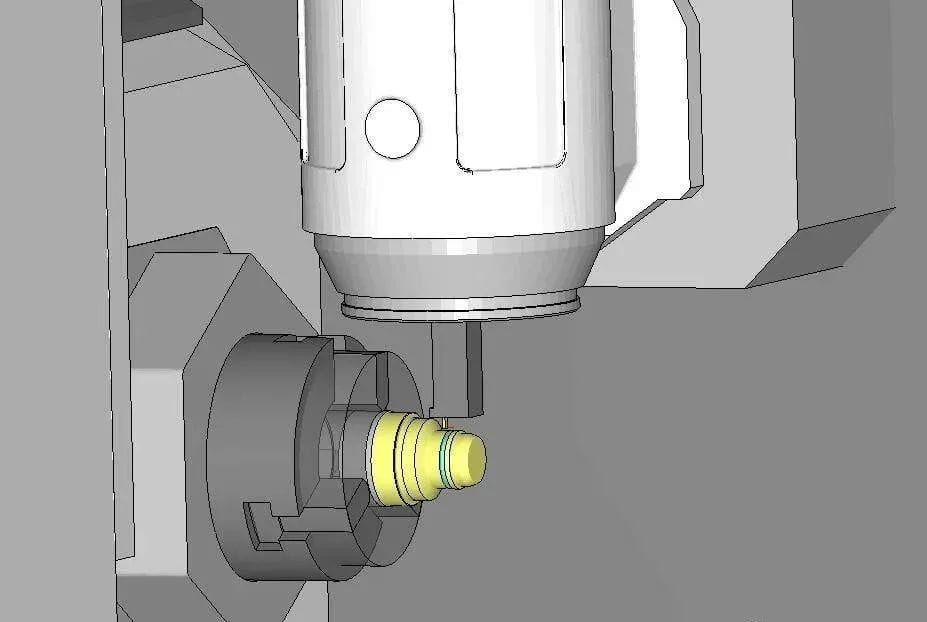

- Be familiar with the tool magazine mechanism and tool changing principle.

Without more than 3 years of training, it would be difficult to meet the requirements listed above.