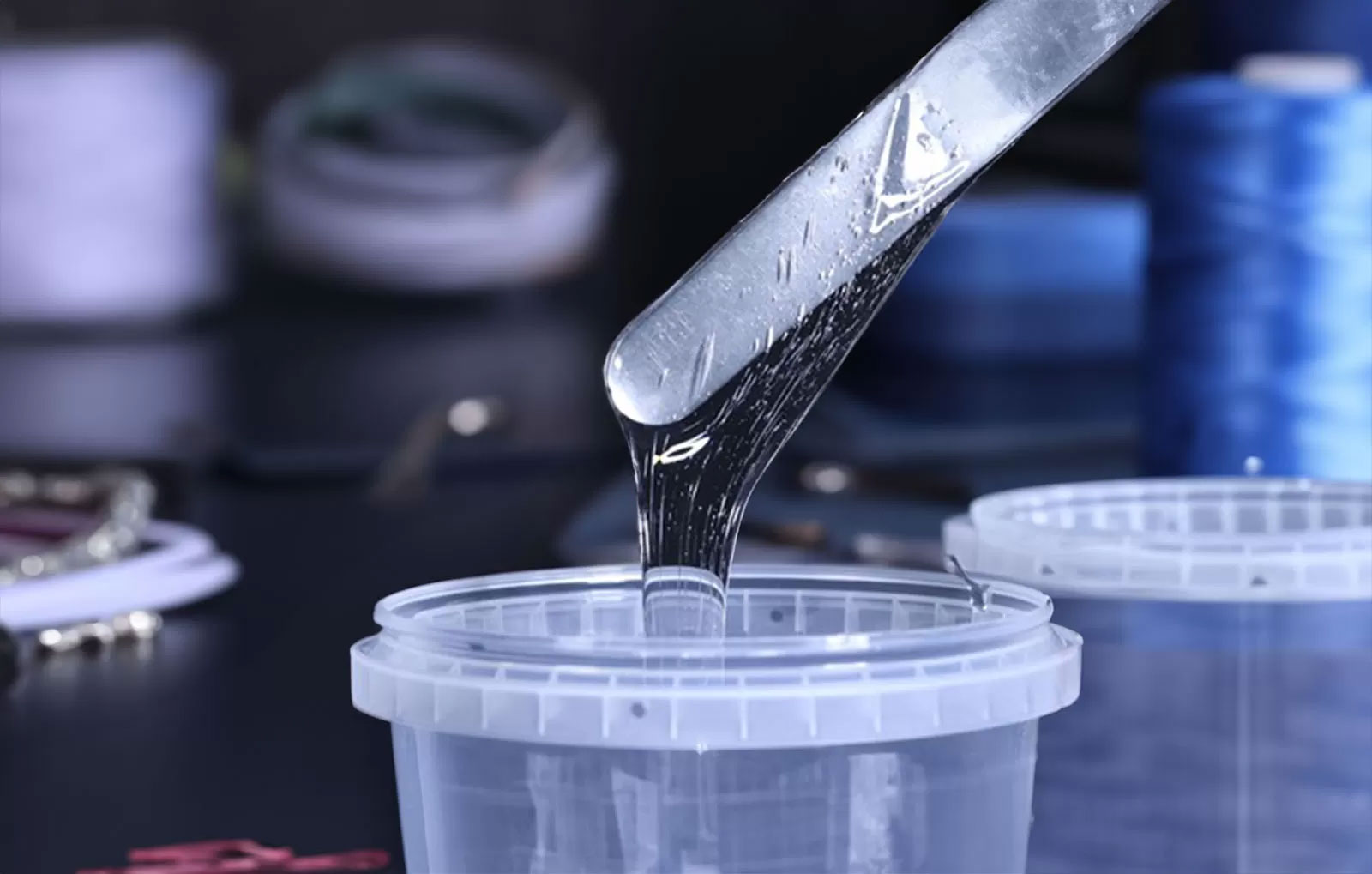

In the production process of silicone products, demoulding is a crucial step, but it is often difficult to demould the molded parts, which not only affects production efficiency but may also lead to product quality problems. The following methods can avoid silicone products being difficult to demould:

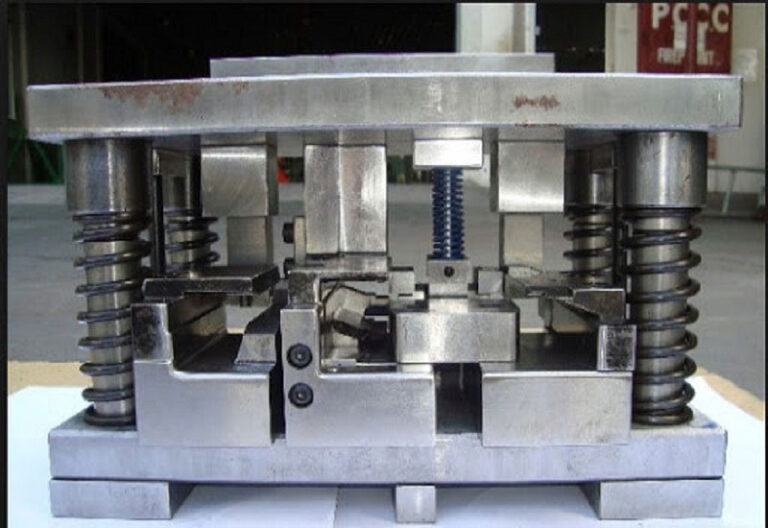

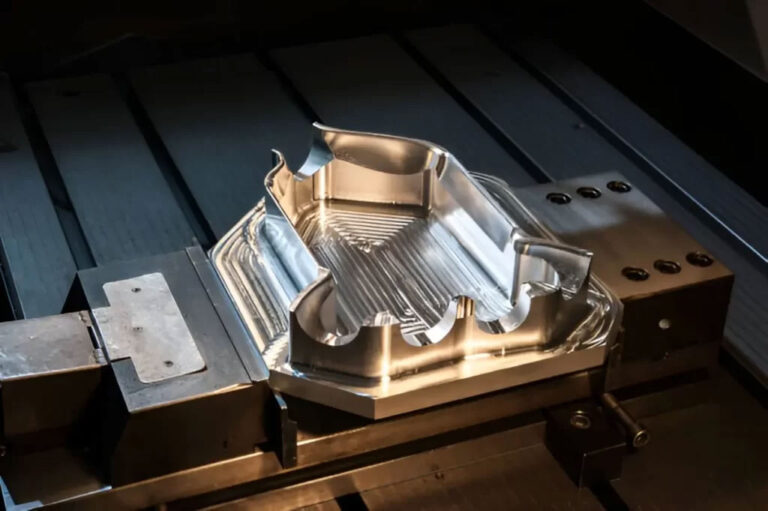

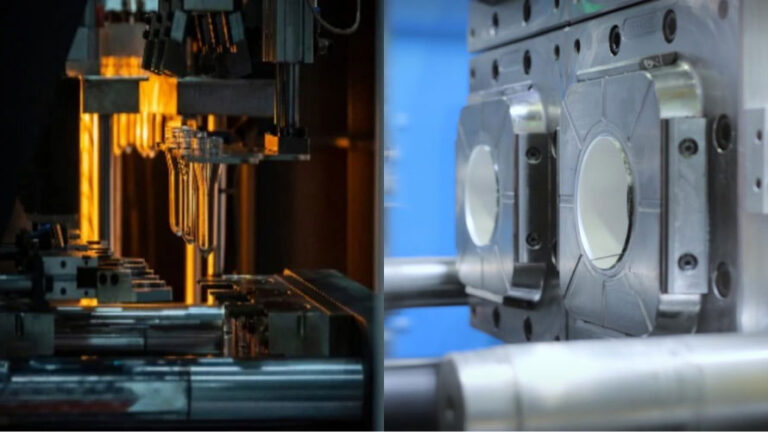

Surface treatment of mold

1: Sandblasting: The new mold must be sandblasted before being put into the oil pressure molding machine to increase the friction of the mold surface, which is conducive to better demolding of silicone products.

2: Choose appropriate mold washing sand: Different mold washing sand should be selected for male and female molds to ensure the best demolding effect.

3: Heating the mold: The sandblasted mold must be heated to a sufficient temperature before placing it in the mold. This will increase the adsorption force of the mold surface and facilitate better adhesion of the silicone product before molding.

4: Spraying the release agent: During the molding process of the silicone product, if the mold is accidentally stuck, you can use a spray bottle or other tools filled with clean water to spray on the side of the product you want to stick to, and then continue molding. The product will stick to the desired place.

Adjust mold temperature

The relationship between mold temperature and product: Products usually like to stick to the lower mold temperature. Therefore, during molding, the adhesion position of the product can be controlled by adjusting the upper and lower mold temperatures, making demolding easier.

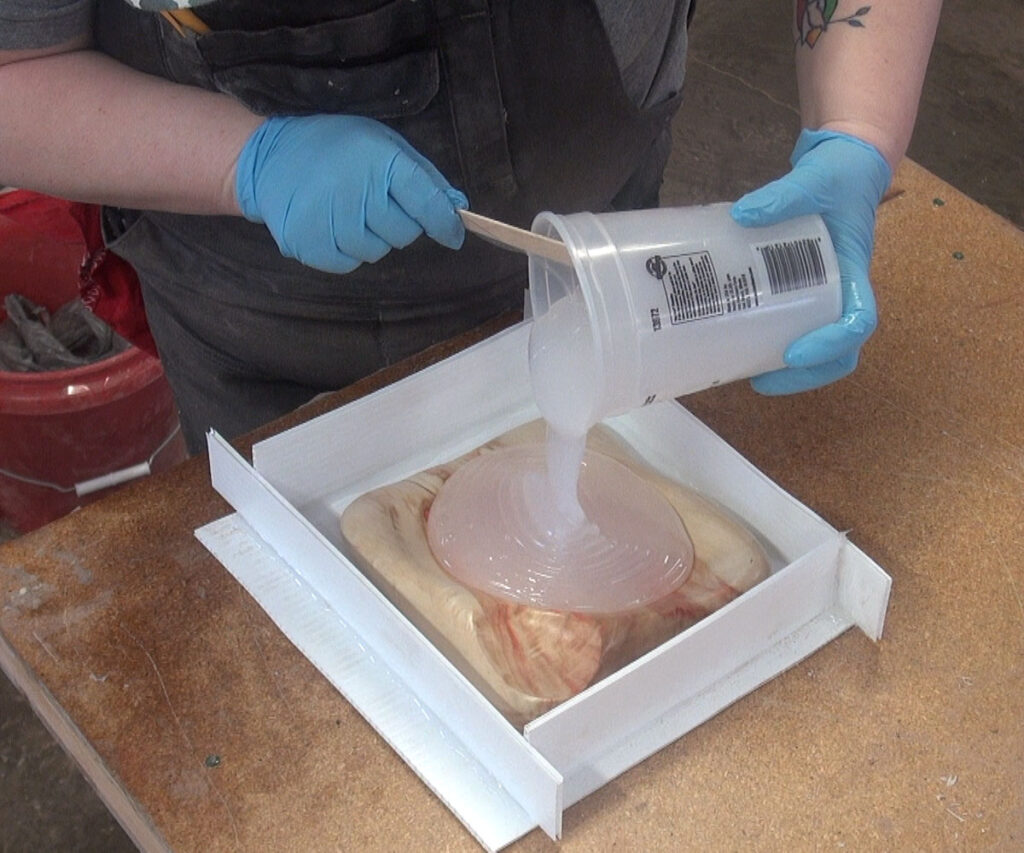

Control the use of release agent

1: Use an appropriate amount of release agent: Be sure to spray the release agent before molding, but be careful not to spray too much, so as not to make the mold surface dirty, affecting the appearance of the product and the adhesion ability of subsequent silk screen printing and oil spraying.

2: Avoid frequent re-spraying of release agent: The release agent is a water-based agent and is easy to volatilize, so it needs to be re-sprayed regularly, but this will increase the workload.

Use internal mold release

Add internal mold release agent when preparing materials: If the above method is not effective, you can consider adding an appropriate amount of internal mold release agent to the rubber compound when preparing the materials, but this will increase the additional cost of the product.

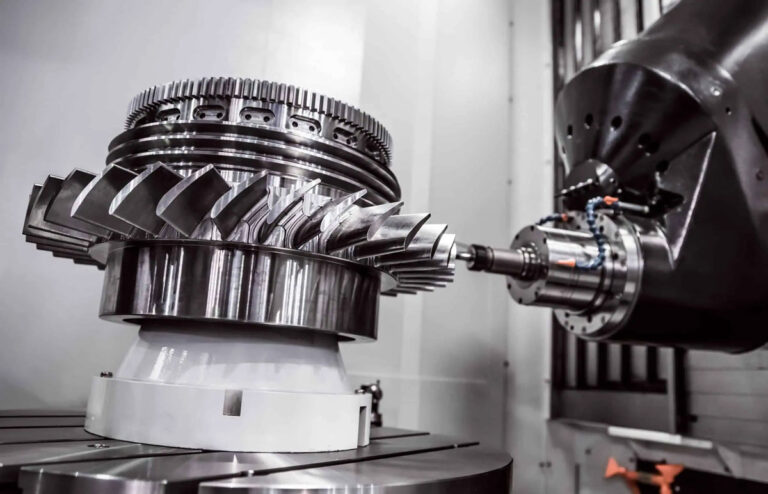

Mold design and raw material selection

1: Rationality of mold design: Unreasonable mold design is also one of the reasons for bubbles in silicone molding. Therefore, optimizing the mold design can effectively avoid demoulding problems.

2: Raw material selection: If the mold is too dirty or there are too many impurities on the viscose surface, it is necessary to replace the raw materials or vulcanizing agent to increase the fluidity of the raw materials, reduce the hardness, and thus improve the demolding effect.

Through the above method, the problem of silicone products being difficult to demould can be avoided to a large extent, and production efficiency and product quality can be improved.