Brief Intro

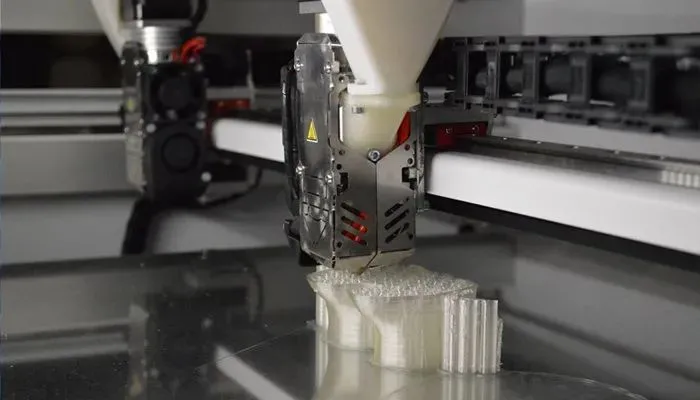

FDM 3D printing is one of the most widely used 3D printing technologies, and basically all FDM 3D printers use PLA and ABS filaments as printing materials.

However, this situation has changed now, and some FDM 3D printers have begun to use plastic particles as printing materials.

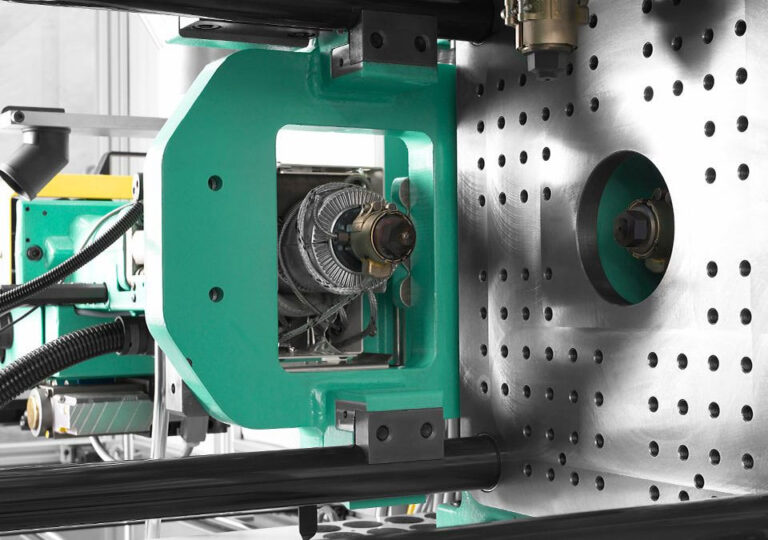

Plastic granules have always been used mainly for injection molding, including the filaments used in 3D printing, which are also made of plastic granules .

When 3D printing with plastic pellets, the extrusion method and filament are slightly different.

Plastic particles are placed in a funnel-shaped container and enter the melting zone at a certain speed. The plastic particles are melted into a paste by heat and then extruded onto the printing platform through the nozzle.

Advantages

Compared with filaments, printing with plastic pellets has the following advantages:

1.Lower material costs

Since wires are made of plastic pellets, using plastic pellets directly saves one step, and the cost of pellets is about 65% to 90% of the wire;

2.Faster printing speed

Because the pellet bin can be preheated in advance, the throughput can reach 100 times that of wire, and the extrusion speed can reach 200 times.

3.Better mechanical properties

When making wire from plastic pellets, heating is required, which will cause some loss of performance. However, directly melting plastic pellets avoids this problem.

4.Recycling

Not only 3D printed plastic parts, but other plastic products can also be used as printing materials after being cleaned and crushed into particles.

Disadvantages

1.The printing process is irreversible. When printing with filament, you can pause or cancel it at any time. When printing with particles, there is no such flexibility and the printing must be completed in one go.

2.The surface is rougher and the stability is not as good as wire, which may cause problems such as gaps and warping.

3.The fineness is relatively low . The wire can accurately control the extrusion speed to obtain the corresponding fineness. The printing flow rate control of particles cannot be as precise as that of wire.

Conclusion

After the above comparison, considering their advantages and disadvantages, granular materials are suitable for printing large plastic parts, such as various furniture, ship parts, etc.

Wire materials are stable for printing and are suitable for printing small plastic parts and plastic parts with certain requirements for precision.