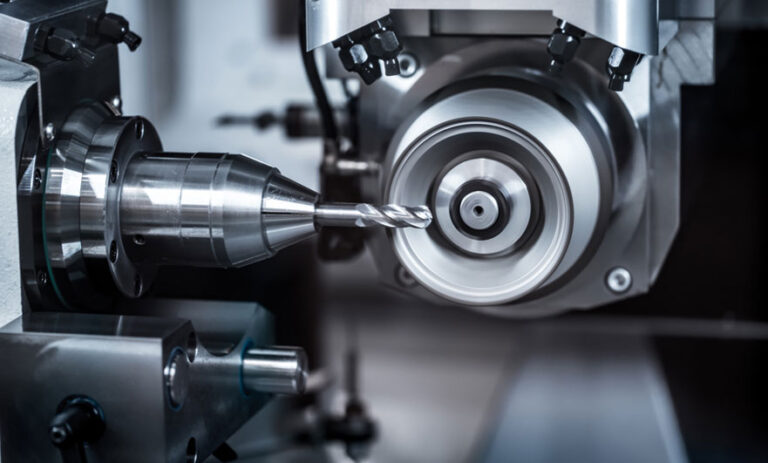

Laser Cutting

One of the key methods for cutting sheet metal is using a laser cutter. Laser cutting uses a high-energy beam intensified by lenses or mirrors to burn/vaporize the material to create the cut.

This is a very fast and precise sheet metal cutting method, and because the heat-affected zone is smaller, the likelihood of warping is reduced. CO2 and fiber lasers are the most commonly used, capable of cutting material up to 10 mm thick.

Water Jet Cutting

Another sheet metal cutting method is water jet cutting. Water jet cutting uses a very high-pressure jet of water (which can also be mixed with an abrasive) to create cuts in the material.

It is an advantageous manufacturing method over laser cutting when cutting low-melting-point materials like plastics and aluminum, preventing unwanted deformation.

Plasma Cutting

The third and most powerful sheet metal cutting method is plasma cutting. Plasma cutting works by creating an electrical channel of extremely hot, ionized gas (plasma), which melts the material to create the cut.

It is an effective method for cutting materials thicker than 10 mm, but the cutting precision is not the same as with laser or water jet cutting.

The guillotine

Sheet metal guillotine is an efficient method for creating clean, accurate cuts in sheet metal. The sheet is fed between two blades, which are then compressed together with great force to deform the sheet until a cut is finally produced.

The guillotine is a fast and inexpensive method for producing high-quality cuts, although it does slightly deform the metal edge.

Sheet Metal Stamping

It uses a cutting mechanism similar to a guillotine, however, it uses a shaped metal tool (called a die) to perform the cut.

The die is forced into the sheet metal at high speed to perforate the metal. Standard dies (round, square, rectangular) are commonly used, but custom tools can be made to punch more complex shapes. Due to the cost of manufacturing the die, this method is more suitable for high-volume production.

Bending

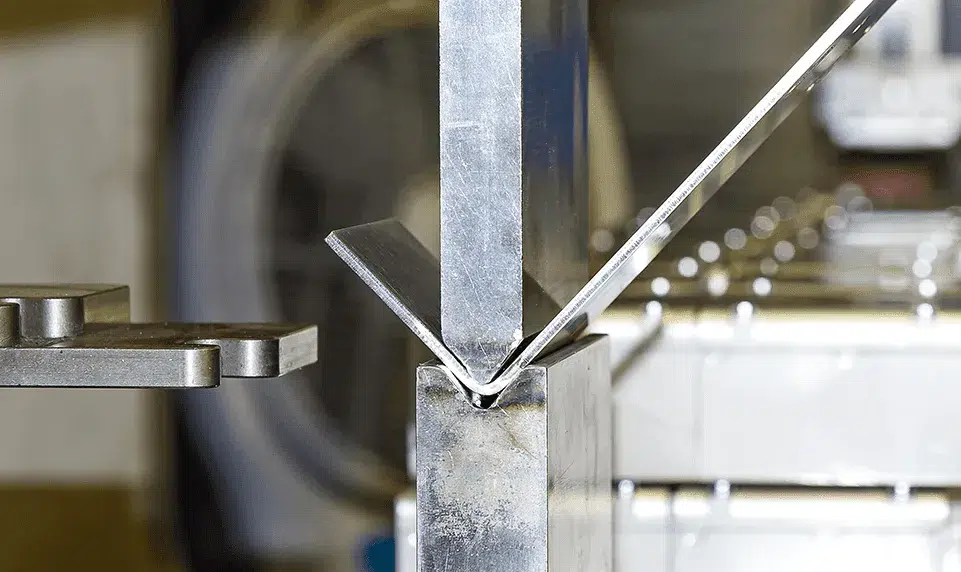

Bending is a fundamental manufacturing process for forming sheet metal into functional components. Sheet metal is bent using a machine called a press brake, which consists of an upper tool (punch) and a lower tool (V-die).

The material is placed between the tools, and the punch presses down into the V-die to form the bend. The bend angle is determined by how deeply the punch presses into the V-die.

Cutting

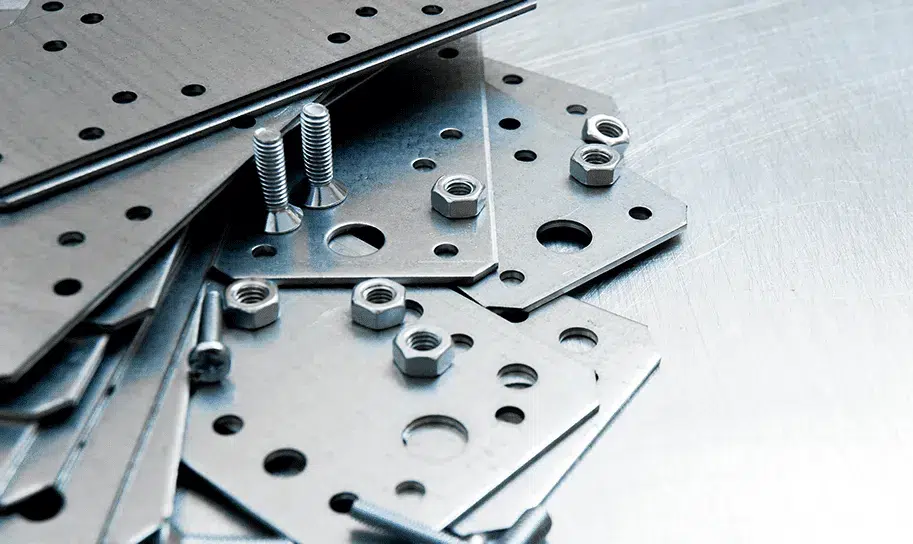

Cutting and bending are two ways to form sheet metal; assembly is the third. Sheet metal parts can be assembled using mechanical fasteners like bolts, screws, and rivets.

Or they can be joined using welding, a process in which two or more parts are fused together using high temperatures and then cooled to form the connection.