Many novices don’t know how to use mold silicone after buying it, and they worry about wasting materials if they operate it incorrectly. Here we will give you a super detailed diagram of how to use mold silicone. Each step of the operation in this tutorial has detailed instructions and precautions, which is very suitable for novices to learn.

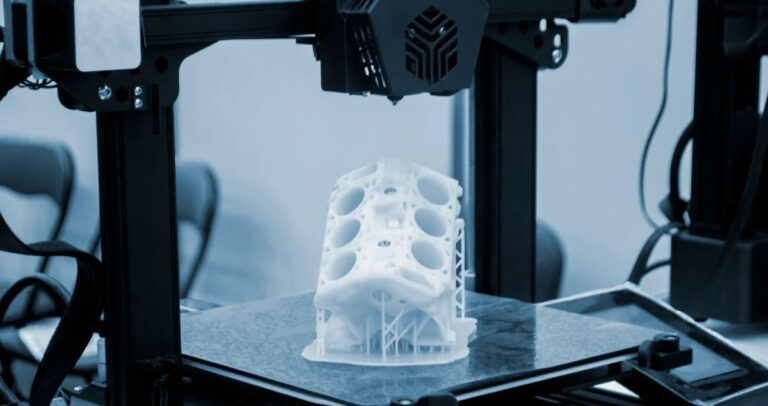

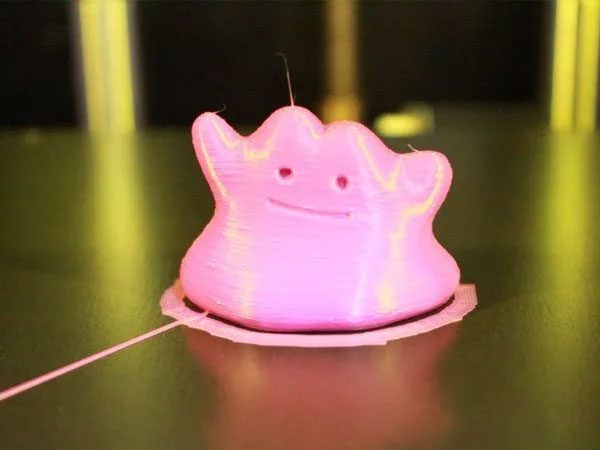

- Prepare the model: The model can be a physical model around you or a 3D printed resin model.

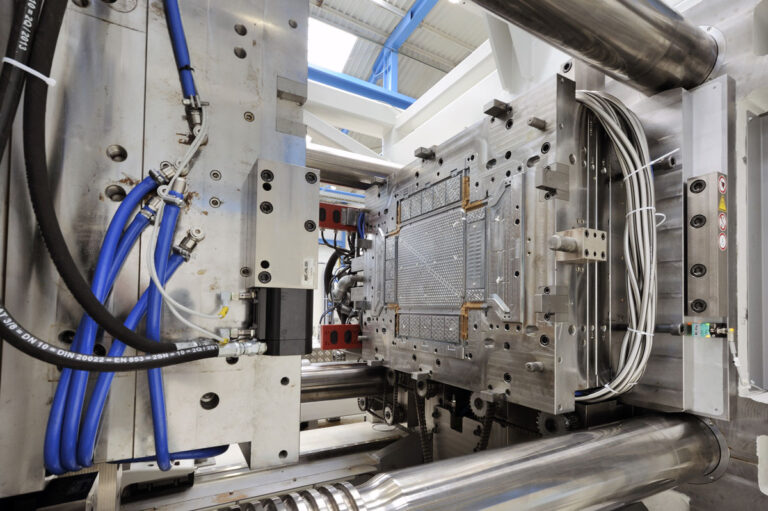

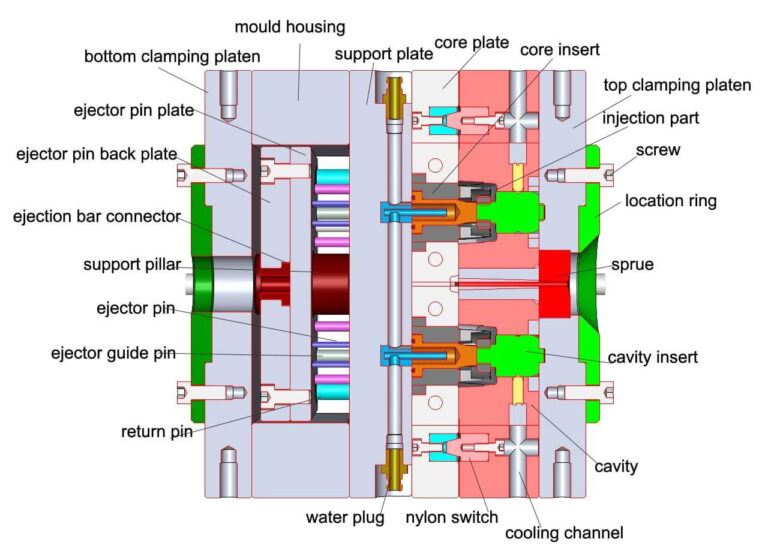

- Fix the model: Set up a suitable mold box according to the size of the model, and then fix the model in the middle of the mold box. Note that if it is not fixed, the model will shift or float after pouring the silicone.

- Prepare silicone: weigh the silicone and curing agent in a ratio of 100:2 (100:1-100:3 is suitable). If there is too much curing agent, the silicone may cure too quickly, causing bubbles to be trapped and unable to be discharged, forming bubble holes. If there is too little curing agent, it will not cure or will take a long time to cure.

- Mix the silicone and curing agent: Mix the weighed silicone and curing agent together and stir them thoroughly with a stirring rod. If color paste is added, you can check whether the silicone and curing agent are mixed evenly by the color mixing effect.

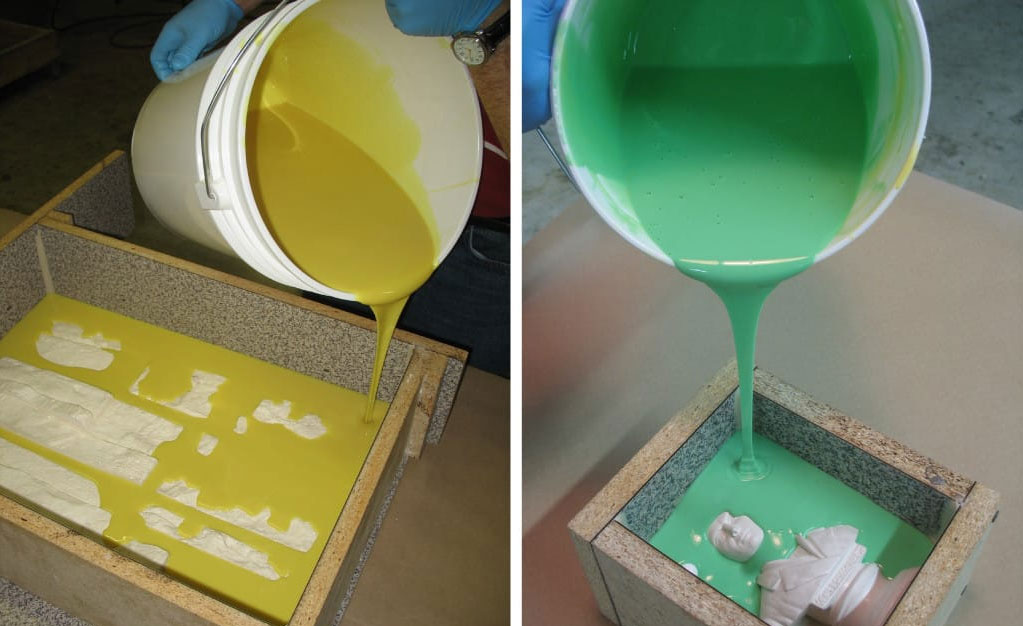

- Pour in silicone: Pour the mixed mold silicone into the mold box. Note that pouring slowly at a high distance can effectively reduce bubbles.

- Curing and demolding: Usually, the mold silicone can be completely cured in 6-8 hours at room temperature, which is related to the proportion of curing agent added and the temperature. After curing, remove the mold box, use scissors to clean the protruding messy silicone around the silicone mold, and separate and take out the model.

- Complete the silicone mold production.