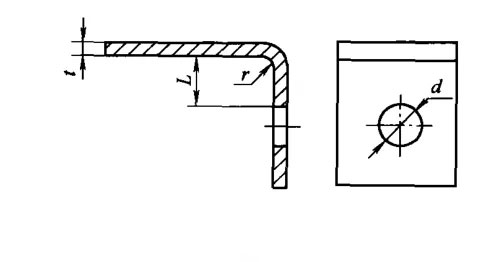

To improve processing efficiency and manufacturability, holes and slots on bent parts are usually pre-machined on the blank before bending. If the holes and slots are located within or too close to the bending deformation zone, they will deform. To prevent deformation, the holes and slots must be positioned a certain distance outside the deformation zone (see figure below).

This distance is called the minimum distance from the hole or slot wall to the bending edge. Typically, the minimum distance L from the hole wall to the bending edge is related to the material thickness and the bending radius r.

Minimum distance between the edges of a round hole

As shown in the diagram above, based on experience, generally:

When t < 2 mm, take L ≥ r + t;

When t≥2mm, take L≥r+2t.

When r=t, the minimum distance from the hole wall to the bent edge is shown in the table below.

Minimum Distance from Round Hole Wall to Bend Edge when r=tr=t

(Unit: mm)

| Sheet Thickness t | 0.6 ~ 0.8 | 1.0 | 1.2 | 1.5 | 2.0 | 2.5 |

|---|---|---|---|---|---|---|

| Min. Hole Edge Distance | 1.3 | 2.0 | 2.4 | 3.0 | 6 | 7.5 |

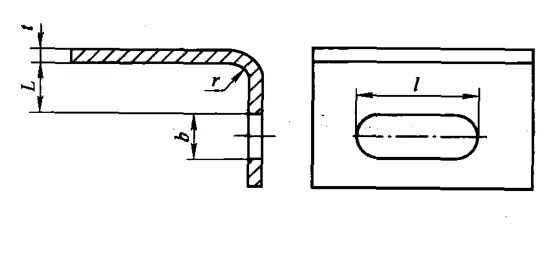

Minimum distance between the edges of oblong and rectangular holes

As shown in the figure above, when the distance between the wall of an oblong (or rectangular) hole and the bending edge is too close, the hole wall will be in or near the bending deformation zone.

The contact area between the hole wall and the bending die is too small, making it difficult to generate sufficient bending moment and corrective force, causing deformation of the hole shape.

Therefore, the distance between the wall of an oblong (or rectangular) hole and the bending edge should not be too small; its value should be greater than the minimum hole edge distance. Recommended minimum distances between the wall of an oblong hole and the bending edge are shown in the table below.

Recommended Minimum Distance from Slot Hole Wall to Bend Edge

(Unit: mm)

| Slot Length L | <26 | 26∼50 | >50 |

|---|---|---|---|

| Min. Hole Edge Distance | 3t + r |

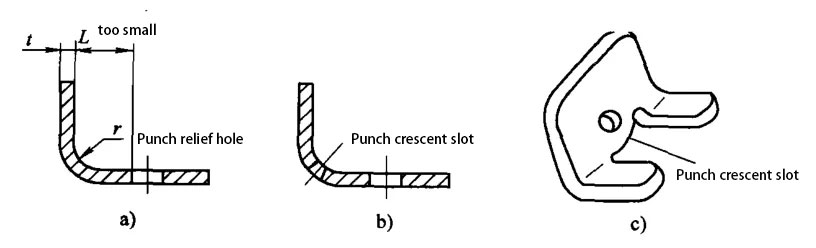

Process measures when the distance from the hole wall to the bending edge is too small

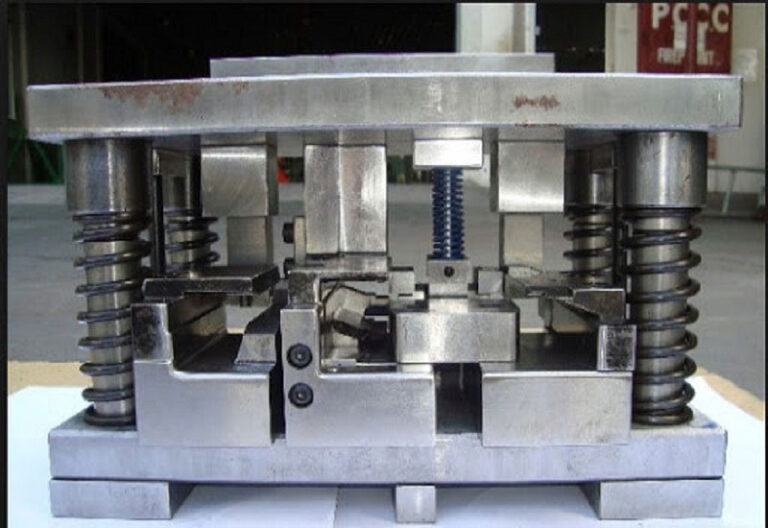

When the distance from the hole wall to the bending edge is less than the minimum hole edge distance (see Figure a), the hole will be severely deformed after bending. In this case, appropriate process measures should be taken according to the requirements of the product part drawing. For example, process holes can be punched on the bending line first (see Figure b) or process grooves can be machined (see Figure c) to prevent the hole from deforming during bending.

When the part has high requirements for the size and positional accuracy of the hole, it is best to machine the hole or groove after bending. When the part’s manufacturability allows, a smaller bottom hole or groove can also be machined on the blank first, and then the hole can be further machined (such as enlarging the hole) to meet the drawing requirements after bending.