Introduction

The cost code of sheet metal design: systematic strategy and refined practice to create the ultimate cost-effectiveness

In today’s highly competitive manufacturing environment, product success depends not only on functional innovation and market positioning, but also on achieving optimal cost-performance. For sheet metal processing, which is widely used and has a transparent cost structure, cost control is not solely the responsibility of the procurement department but also the core mission of the design engineer. A small design change can potentially result in cost savings of tens of thousands of yuan over the entire product lifecycle.

Cost control is a systematic process encompassing materials, processes, assembly, and management, starting with the designer’s drawings. This article will go beyond the superficial understanding of “saving materials” and comprehensively analyze the systematic strategies and refined practices for reducing costs and increasing efficiency in sheet metal design, from strategic planning to detailed implementation. This will help companies achieve optimal total costs while ensuring product performance.

The Strategic Cornerstone of Cost Control: Deep Integration of DFM and DFA

Before exploring specific optimization methods, we must establish a core understanding: 70% of product costs are determined during the design phase, leaving limited room for cost optimization in subsequent manufacturing and procurement stages. Therefore, the most fundamental cost control approach is to incorporate “Design for Manufacturing (DFM)” and “Design for Assembly (DFA)” concepts into the early stages of design to eliminate cost waste at the source.

1, DFM (Design for Manufacturing): Making Parts Easier to Manufacture

The core goal of DFM is to ensure that sheet metal parts can be manufactured efficiently and with high quality. The core principles include:

- Adapt to standard processes: Avoid designing structures that exceed the capabilities of conventional sheet metal equipment (such as too small a bend radius, too deep a stretch feature), reducing the need for custom equipment or secondary processing;

- Simplify the processing flow: Use a single process (such as laser cutting + bending) to replace multiple complex processes (such as cutting + welding + polishing), reducing process switching costs;

- Compatible with mass production: The design takes into account the stability of subsequent mass production to avoid the increase in scrap rate due to slight dimensional deviations.

2, DFA (Design for Assembly): Making Parts Easier to Assemble

DFA focuses on the efficiency of assembling parts and other components. Its core principles include:

- Reduce the number of parts: Through structural integration, multiple parts that need to be assembled are simplified into a single sheet metal part (such as a one-piece bent bracket instead of a multi-piece welded structure);

- Simplify the connection method: give priority to using quick connection structures such as riveting and snap fastening to replace time-consuming processes such as welding and bolt fastening;

- Error-proofing design: Features such as positioning bosses and guide holes are used to avoid incorrect directions during assembly and reduce rework costs.

The integration of DFM and DFA requires designers to have both “manufacturing thinking” and “assembly thinking” – not only to consider the processing difficulty of individual parts, but also to predict their role in the assembly of the entire machine, and weigh every design decision from the perspective of the entire product life cycle.

Material Strategy: Control Costs from the Source

Material costs typically account for over 50% of the total cost of sheet metal parts, making them the primary focus of cost control. Optimizing material usage requires focusing on three key dimensions: precise material selection, improved utilization, and waste recycling.

1, Accurate material selection: Avoiding “overperformance”

The core of material selection is “matching needs” rather than blindly pursuing high-specification materials. Specifically, we can start from the following two points:

- Matching performance to the application: Determine the material type based on the product’s usage environment. For example, internal brackets for indoor equipment don’t require 304 stainless steel; phosphate-treated SPCC cold-rolled steel can meet rust-proof requirements. For outdoor cabinets that don’t require lightweighting, high-quality galvanized steel (AG) offers a much higher cost-performance than aluminum.

Thickness Optimization: Using simulation to reduce costs: CAE (Computer-Aided Engineering) software is used to analyze strength and stiffness, allowing plate thickness to be reduced while maintaining performance. For example, simulations have shown that the thickness of a common 1.5mm cold-rolled plate can be reduced to 1.2mm, directly reducing material costs by 20%. This also reduces the required press brake capacity and reduces processing energy consumption.

2, Maximizing material utilization: Layout optimization is key

Every 1% increase in material utilization has a significant cost-saving effect on mass production. The core method is “nesting optimization” – using professional nesting software to optimally arrange the 2D unfolded drawings of multiple parts on a standard sheet material. Designers need to actively participate and provide design support:

- Design collaboration: Fine-tune the shape to reduce waste: Without affecting the function, fine-tune the local structure of the part (such as changing the rectangular lug to a trapezoidal shape, optimizing the edge of the special-shaped hole) to enable tighter nesting during layout and reduce gap waste;

- Common cutting: Saves material and increases speed: Reserve space for common cutting of adjacent parts during design (i.e. two parts share one cutting line), which not only reduces material waste but also shortens the laser cutting path and improves processing efficiency;

- Adapt to standard plate widths: Design the unfolded dimensions of the parts to be approximate multiples of commonly used standard plate widths (such as 1000mm×2000mm, 1250mm×2500mm) to avoid the premium brought by using special-sized plates (special plate widths usually require an additional processing fee of 10%-20%).

3, Waste Management: Uncovering “Surplus Value”

Large waste materials generated during production (such as sheet metal skeletons after laser cutting) are not worthless and can be reused in the following ways:

- Reuse of small parts: Evaluate the size of large scraps and use them to produce small auxiliary parts (such as gaskets and fixings), reducing the investment in new plates;

- Supply chain collaboration: Establish a waste recycling mechanism with suppliers, and hand over waste that cannot be reused internally to suppliers for processing in exchange for a certain cost rebate or purchase discount.

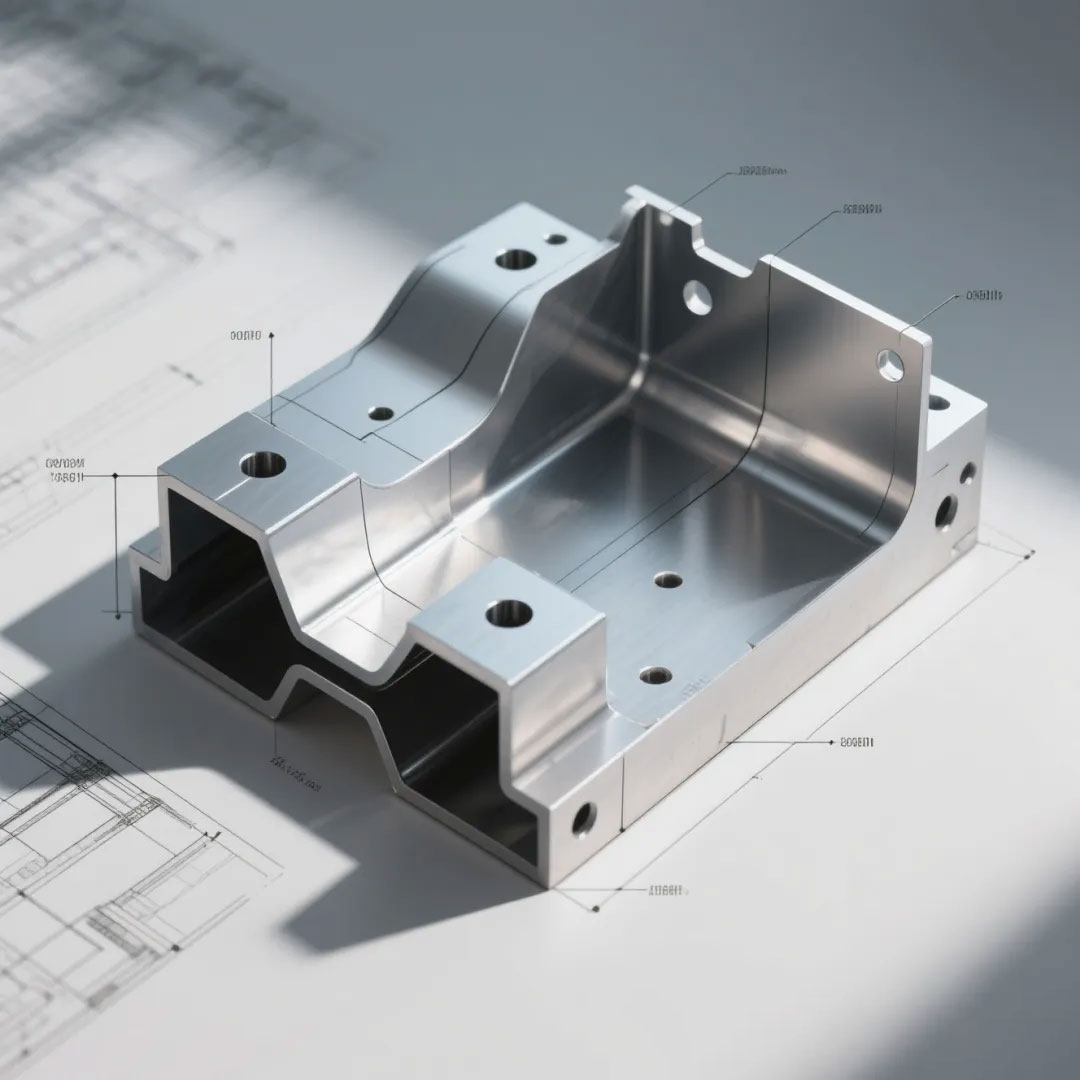

Design Optimization: Exploiting Cost Potential from Geometric Shapes

The core wisdom of sheet metal design lies in achieving complex functions with the simplest geometric structures. Through the three key approaches of “parts consolidation,” “feature simplification,” and “tolerance rationalization,” processing and assembly costs can be significantly reduced.

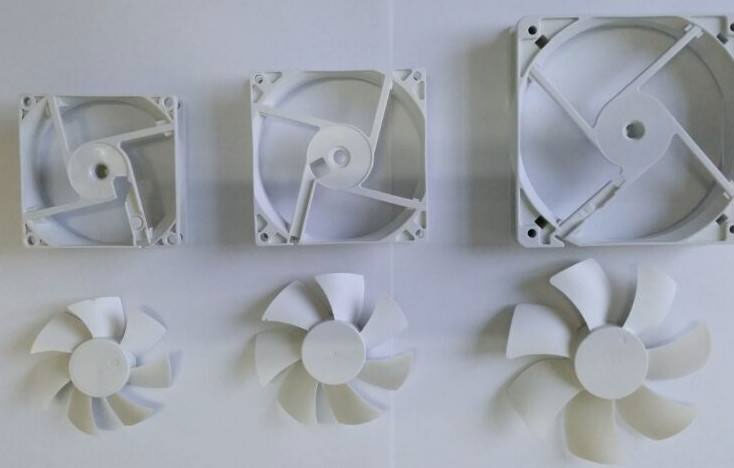

1, Part Consolidation: Replace multiple processes with one

Parts consolidation is a cost-reducing tool in sheet metal design. Its core approach is to combine multiple parts that originally required assembly into a single sheet metal component through processes such as bending, riveting, and embossing. Specific benefits include:

- Reduce molds and materials: After integration, the number of parts is reduced, and the corresponding number of stamping molds and material codes is also reduced, reducing inventory management costs;

- Eliminate assembly time: Eliminate welding, bolt tightening and other processes. Taking a “one-piece bent bracket” as an example, compared with a three-piece welded structure, it can save more than 80% of assembly time;

- Improved reliability: Reducing the number of connection points (such as welds and bolts) reduces the risk of product failure due to connection failure, and subsequent maintenance costs are also reduced.

For example, the heat dissipation cover of a certain device was originally welded together from three parts: “panel + side panel + fixing ear”. By optimizing the bending path, it was designed as an overall structure of “one-time bending and forming”, which not only eliminates the welding process, but also avoids dimensional deviation caused by welding deformation.

2, Feature Simplification: Say No to “CAD Over-Design”

Drawing complex curves and special-shaped holes in CAD software is very convenient, but the high processing cost is hidden behind it. The core of feature simplification is “prioritizing low-cost processing features”:

- Prioritize standard holes: Round holes, square holes, and waist-shaped holes can be quickly processed by CNC punching machines, and the cost is only 1/3-1/2 of laser-cut special-shaped holes. If a special hole shape is required, try to split it into a shape composed of standard features (for example, using “round hole + rectangular hole” instead of an irregular oblong hole).

- Corner fillet standardization: Unify all bending radii and hole fillets to 1-2 standard values (such as 1.5mm, 2mm), reducing the number of bending machine commissioning times (each radius change requires recalibrating the mold, which takes 5-10 minutes) and the types of stamping dies;

- Avoid redundant features: Cancel decorative features that have no functional significance (such as complex edge chamfers and unnecessary convex hulls). These features not only increase processing time but may also affect subsequent assembly.

3, Tolerance rationalization: rejecting the “one-size-fits-all” high-precision requirements

Sheet metal belongs to plastic processing technology, and the conventional accuracy range is ±0.5mm-±1mm. If a tolerance of ±0.1mm is required, additional secondary processing such as milling and grinding will be required, and the cost will increase exponentially. The core of tolerance rationalization is “function orientation”:

- Strict control of key dimensions: Only dimensions that affect assembly and function are strictly marked with tolerances (such as the spacing between mounting holes and the height of positioning bosses that match other parts). The tolerance level is usually ±0.2mm-±0.3mm;

- Non-critical dimension tolerance: For non-visible areas and dimensions without matching requirements, adopt the loose ISO 2768-mK tolerance (linear dimension tolerance ±1mm, angular tolerance ±1°) or the company’s customized loose tolerance;

- Trust in process capabilities: Avoid marking all dimensions with “±0.1mm”. Excessively tight tolerances not only increase costs but may also lead to increased scrap rates due to process failures.

Process Selection: Weighing the Cost-Effectiveness of Manufacturing Paths

The same function can be achieved through a variety of sheet metal processes. Choosing the optimal process path is key to cost control. Three key scenarios require special attention: “connection process,” “bending vs. welding trade-off,” and “efficient process replacement.”

1, Cost game of connection technology: How to choose between pressure riveting, welding and pull riveting?

The costs of different connection processes vary significantly and need to be selected based on production scale and structural requirements:

- Press riveting (PEM): Initial investment in press riveting dies (cost 500-2000 yuan), but the processing time per piece is only 5-10 seconds, suitable for batches greater than 1000 pieces, and the cost per piece is about 0.1-0.3 yuan;

- Welding: No mold is required, but professional welders are required (labor cost 60-100 yuan/hour). The processing time for a single piece is 30-60 seconds. Subsequent grinding and anti-rust treatment are also required. It is suitable for batches of less than 500 pieces or complex structures.

Pop Riveting: This method has low tool costs (a rivet gun costs only a few hundred yuan) and can be operated on one side. However, it is inefficient (15-20 seconds per piece) and has poor strength. It is suitable for small-batch repairs or where double-sided operation is not possible.

Taking a batch of 10,000 sheet metal brackets as an example, the total cost of the riveting process (mold + labor) is about 3,000 yuan, while the labor cost of the welding process is about 16,000 yuan. The economic advantage of riveting is significant.

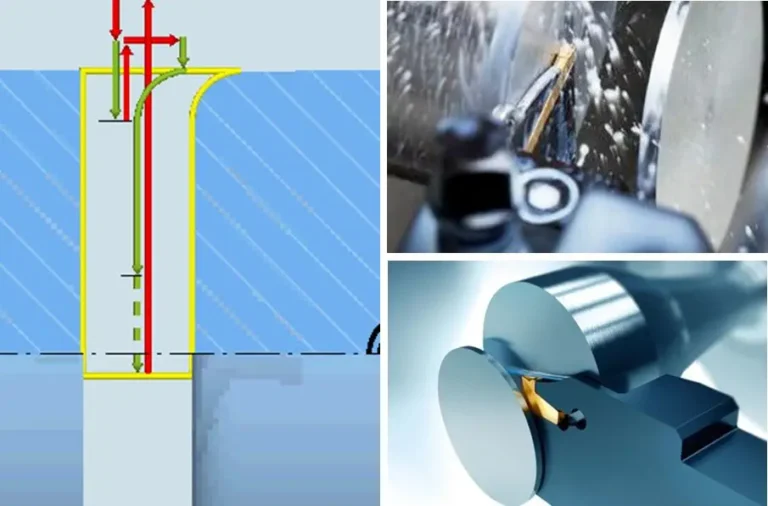

2, The trade-off between bending and welding: one more bend, one less weld

The cost of bending process is usually lower than welding. If one bending process can be added instead of one welding process, the cost can often be greatly reduced. For example:

The L-shaped bracket of a certain piece of equipment was originally designed as two flat plates welded together, requiring two processes: welding and polishing. After being optimized to a “one-step bending forming” process, it only requires one bending process, reducing processing time from 120 seconds per piece to 20 seconds per piece, and reducing costs by over 70%.

- Note: If the number of bends exceeds 3 (especially for complex multi-bend structures), the cost of the bending mold and processing time must be evaluated to avoid the cost exceeding the welding cost due to the bending process being too complicated.

3, High-efficiency process replacement: division of labor between laser cutting and CNC punching

Laser cutting and CNC punching are the core equipment for sheet metal cutting. The cost difference between the two is mainly reflected in “batch” and “shape complexity”:

- Laser cutting: Suitable for small batches (less than 500 pieces) and complex shapes (such as special-shaped holes and curved edges). It is charged by cutting time (about 1-2 yuan/minute), but does not require a mold;

- CNC Punching Machine: Suitable for large batches (>1,000 pieces) and regular shapes (multiple standard holes, simple contours). It is charged by the number of punching times (approximately 0.01-0.03 yuan/time) and is 3-5 times more efficient than laser cutting. If the part has a large number of repeated holes, customized composite molds can further improve efficiency (multiple holes can be processed in a single punching).

For example, for a sheet metal panel with 10 round holes in a batch of 10,000 pieces, the processing cost of a CNC punching machine (with a composite mold) is about 2,000 yuan, while the cost of laser cutting is about 15,000 yuan. The former is more cost-effective.

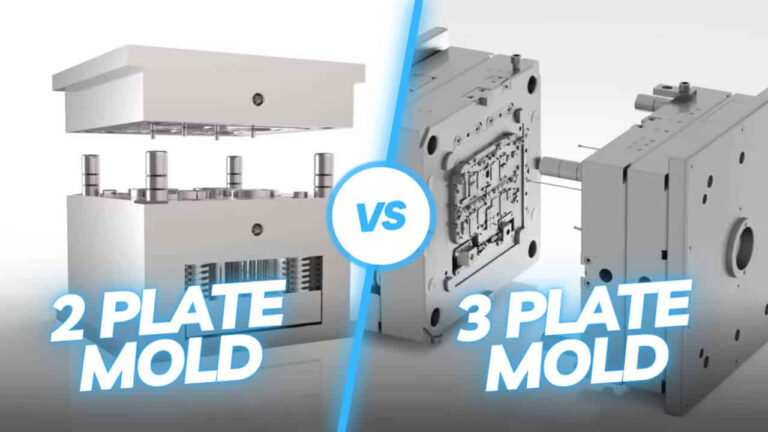

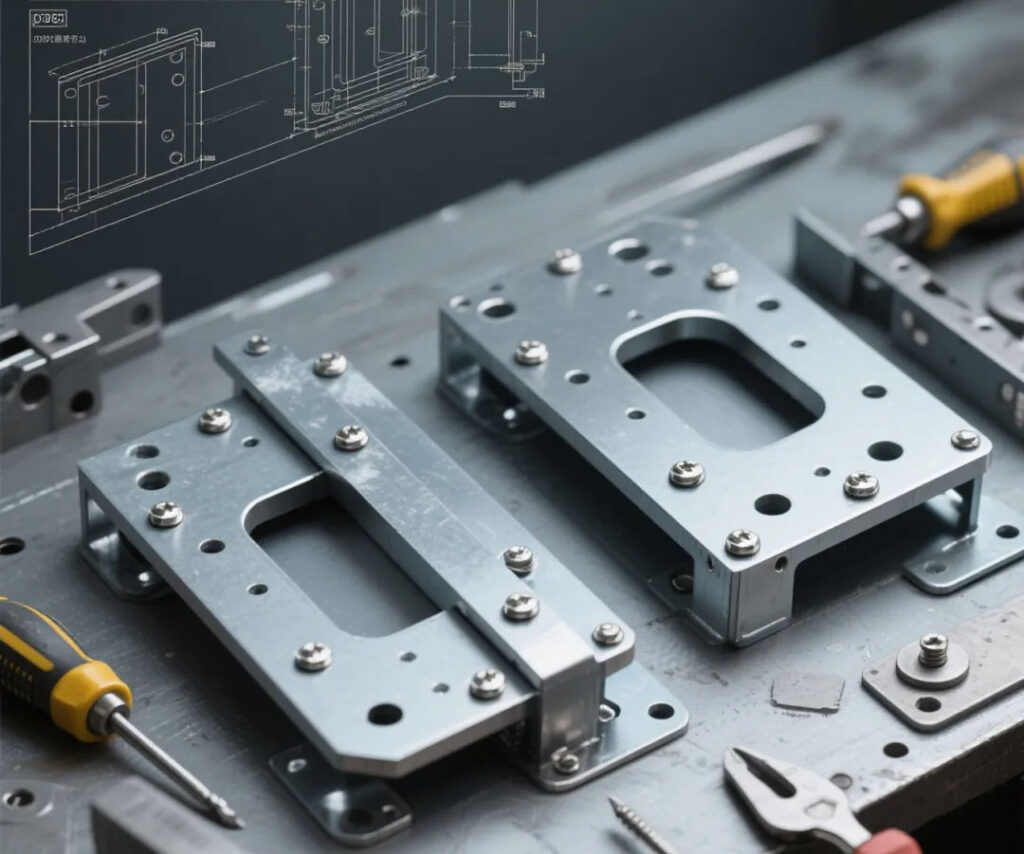

Standardization and modularization: diluting costs through economies of scale

Standardization and modularization are the core means to achieve “low-cost, high-efficiency” mass production. By reducing the types of materials and increasing the reuse rate, the costs of molds, R&D, and management can be diluted.

1, Design standardization: Establishing the company’s “sheet metal design specifications”

Formulate and enforce the “Enterprise Sheet Metal Design Specifications” to clarify the following core standards:

- Material standards: 3-5 common materials (such as SPCC, SGCC, 304 stainless steel) and 4-6 common plate thicknesses (such as 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm) are preferred;

- Process standards: unified bending radius (such as 1.5mm), standard hole size (such as M3, M4 rivet holes), and rivet part model (such as PEM standard rivet nuts);

- Tolerance standards: Clarify the tolerance levels of critical and non-critical dimensions to prevent designers from arbitrarily marking high-precision tolerances.

Direct benefits of standardization: reducing the number of material types (usually by 30%-50%) and lowering inventory costs; increasing the purchase volume of a single material and obtaining bulk discounts from suppliers (doubling the purchase volume can usually reduce the unit price by 5%-10%).

2, Feature modularization: establishing a “standard feature library”

Modularize the commonly used functional structures in sheet metal parts and establish an enterprise-level “standard feature library” so that designers can directly call it without redesigning:

- General functional modules: such as heat dissipation hole modules (louver holes, circular hole arrays), mounting modules (fixing ears, positioning bosses), and protection modules (reinforcement ribs, edge folds);

- Connection modules: such as rivet assembly modules (rivet nut + positioning hole) and snap connection modules (snap + slot).

Benefits of modularization: Designers’ drawing efficiency is increased by 40%-60%; structural differences caused by repeated design are avoided, ensuring product quality consistency; and process debugging time is reduced because the processing parameters of standard modules are solidified.

3, Product Platformization: Using “Common Platform + Differentiated Components” to Reduce Costs

In the design of serialized products, the “product platform” strategy is adopted:

- Common platform: Design a unified core structure including chassis, side panels, and frame as a common platform for a series of products;

- Differentiated components: By replacing a few non-common parts such as the “panel, interface module, and heat dissipation module”, product functions can be differentiated (for example, power supply devices of different power only need to replace the internal heat dissipation module).

For example, a company’s three different models of industrial control cabinets use a unified frame platform (accounting for 60% of the total cost). Only the panels and internal mounting brackets were replaced, which reduced R&D costs by 50%, mold costs by 70%, and production line change time from 2 hours to 30 minutes.

Collaboration and Communication: The Key to Unlocking Hidden Costs

In the manufacturing industry, over 30% of cost waste stems from “information silos”—poor communication between design, process, procurement, and production departments, leading to delayed implementation and repeated revisions of design plans. Early collaboration, digital simulation, and cross-departmental reviews can effectively reduce these hidden costs.

1, Early Supplier Involvement (ESI): Involve process experts early

During the design concept phase, process experts from core sheet metal suppliers are invited to participate in the review to obtain the following key information:

- Material availability: Confirm whether the materials selected for the design are of standard market specifications to avoid extended procurement cycles (usually an additional 1-2 weeks) and cost premiums due to material scarcity;

- Process feasibility: Evaluate whether the design structure can be realized through conventional processes, such as whether the bending depth exceeds the equipment limit and whether the rivet position is convenient for operation;

- Cost optimization suggestions: Suppliers can propose specific solutions for layout optimization and process substitution based on their mass production experience (e.g., recommending replacing laser cutting with CNC punching).

Benefits of ESI: Avoid rework due to process infeasibility after the design is completed (the cost of a single rework is usually greater than 10,000 yuan), while obtaining cost optimization suggestions that are closer to mass production.

2, Digital prototyping and manufacturing simulation: Avoiding problems in advance

Before launching a trial production of physical products, use 3D CAD software to conduct “virtual manufacturing”:

- Sheet metal unfolding simulation: Verify the accuracy of the unfolded dimensions of the parts to avoid the parts being unable to bend due to incorrect unfolded dimensions;

- Bending process simulation: simulates the bending sequence and angle to predict whether there will be interference (for example, whether the part will collide with the mold after multiple bends);

- Assembly interference check: Simulate the assembly of sheet metal parts with other parts (such as plastic parts and electrical components) to detect size mismatches in advance.

The benefits of digital simulation: It reduces the number of physical trial and error (usually from 3-5 times to 1-2 times), and the cost of a single trial and error (materials + labor) is about 5,000-10,000 yuan, which greatly saves trial production costs.

3, Cross-departmental design review: pooling ideas to reduce costs

Establish a cross-departmental review mechanism covering “design-process-procurement-production-quality” and conduct multi-dimensional evaluations before freezing the design plan:

- Design department: explain the design functional requirements and structural ideas;

- Processing department: evaluate the processing difficulty and cost, and make suggestions for process optimization;

- Purchasing Department: Evaluate material procurement costs and cycles, and confirm supplier capabilities;

- Production department: evaluate assembly convenience and production efficiency;

- Quality Department: Evaluate the detectability of dimensional tolerances to avoid unverifiable accuracy requirements.

Benefits of cross-departmental review: Discovering cost risks in the design from different perspectives (for example, the purchasing department may point out the recent price increase of a certain material and recommend replacing it with a more cost-effective alternative), avoiding cost waste caused by single-department decision-making.

Conclusion: Cost control is a culture integrated into design

Cost control in sheet metal design is not simply about “saving materials and reducing processes”, but a systematic project from strategy to details. It requires designers to be not only technical experts, but also product architects who “understand manufacturing, costs, and business.”

From the strategic introduction of DFM/DFA to the detailed optimization of materials, design, and processes, and finally to the economies of scale achieved through standardization and modularization, cost control at every stage must be based on ensuring product performance. True cost optimization lies in finding the optimal balance between performance and cost, ensuring that every design delivers the goal of maximizing value.

Incorporating cost awareness into every detail of the design makes “cost reduction and efficiency improvement” an instinctive response for designers. This way, what is delivered will not only be sheet metal parts that meet the functions, but also commercial products with the ultimate cost-effectiveness that can stand out in the market competition.