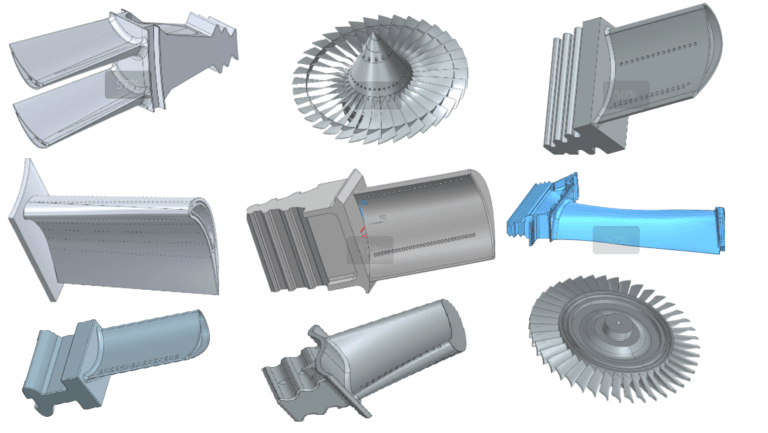

What is a prototype?

Prototype is the first step to verify the feasibility of a product. It is the most direct and effective way to find out the defects, deficiencies and drawbacks of the designed product, so as to make targeted improvements to the defects until no deficiencies can be found from individual prototypes. Prototypes are generally a small number of samples with a short production cycle and less loss of manpower and material resources. They can quickly find out the deficiencies of product design and then improve them, providing sufficient basis for product finalization and mass production.

At present, we usually use the following three processes for prototype production, namely CNC prototype processing, vacuum molding, and 3D printing. Today, Gaofeng will introduce these three processes that we often use when making prototypes. We hope you can have a better understanding of product prototype proofing.

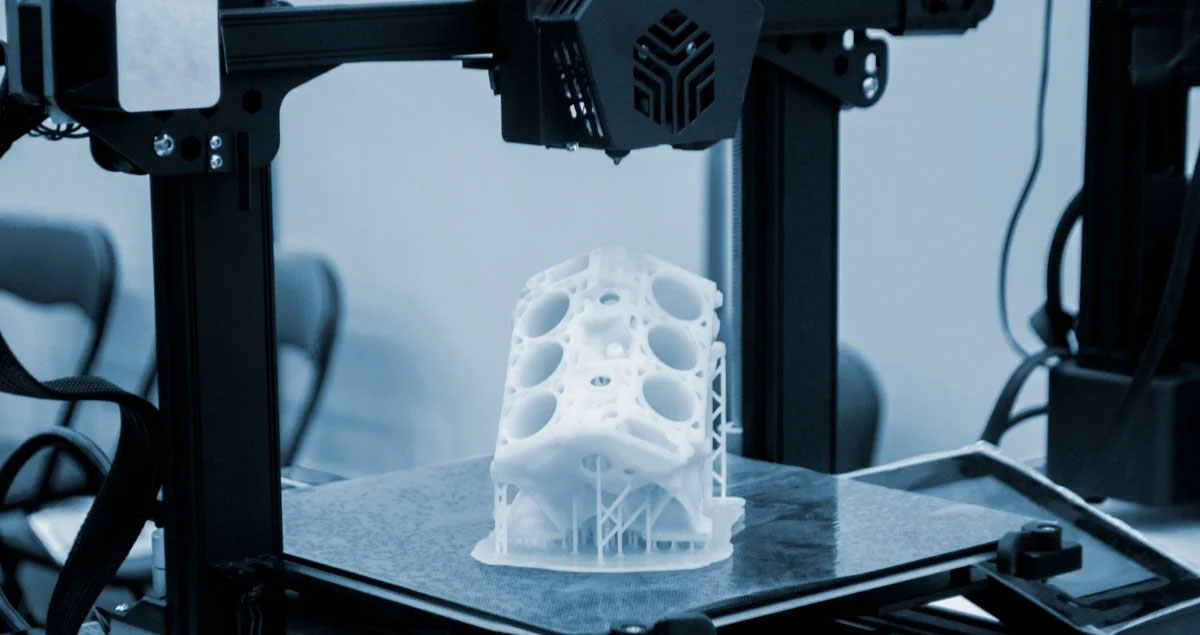

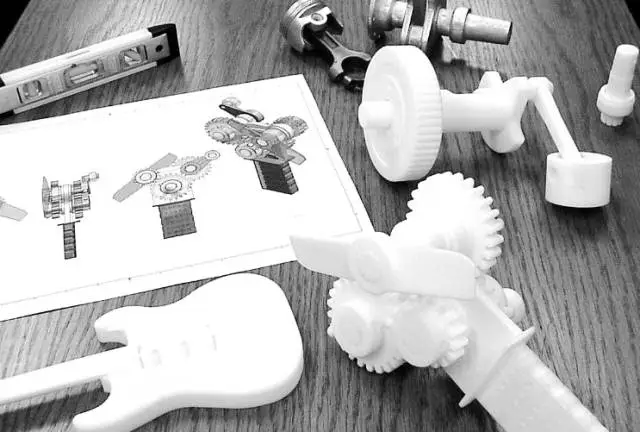

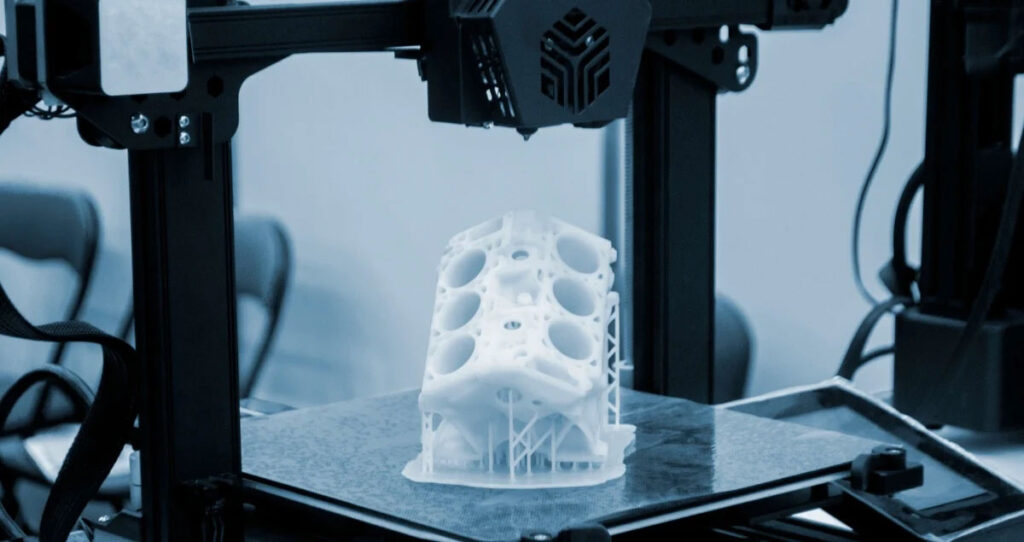

3D Printing Prototype

3D printing is a type of rapid prototyping technology. It is based on digital model files, adds materials little by little to make it take shape, and uses powder, linear plastic or liquid resin materials to construct objects by printing layer by layer.

The main process of 3D printing prototype is:

Drawings – 3D models – Add supports – Model slicing – 3D printing – Post-processing – Finished product

Compared with the above two processes, the main advantages of 3D printing prototypes are:

- Fast production speed of prototype samples

Generally speaking, the speed of printing prototypes using the SLA process is three times that of CNC prototypes, so 3D printing is the first choice for small-scale and small-batch prototype production.

- Save materials

Additive manufacturing saves a lot of materials and costs.

- The 3D printer has full-process automatic processing, high precision of prototype production, small model error, and the minimum error can be controlled within ±0.01mm

- 3D printing prototypes do not require human intervention throughout the process, which avoids errors caused by human factors. CNC prototype production is prone to prototype deformation.

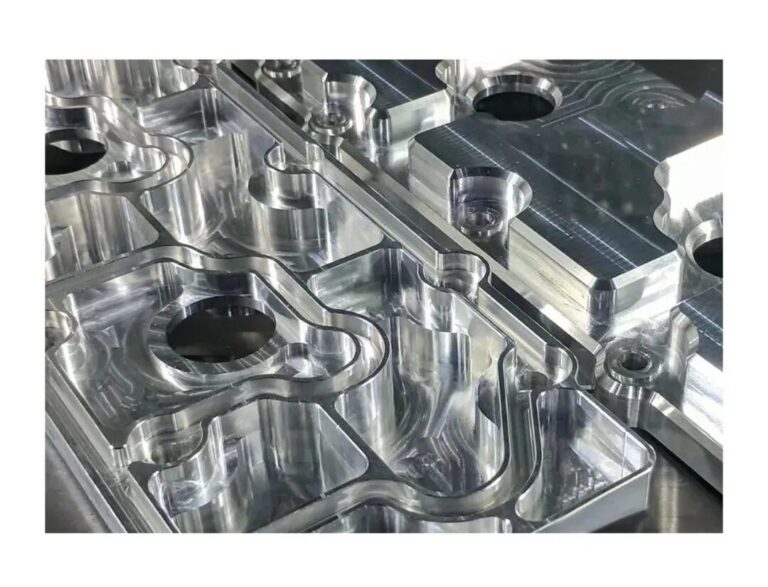

CNC prototype processing

CNC is a computer numerical control machine tool that cuts a whole plate according to a pre-written program. CNC uses the Mastercam system, which is mainly used to control the CNC tool path. CNC milling machines are specially used to process some square and irregular objects, while lathes are used to process round objects. CNC can process some relatively large workpieces. It is cheaper than SLA and can meet many types of prototypes.

CNC prototype model production process:

Drawing → Write program → Transfer program to CNC machining center → Machine processing → Manual post-processing (grinding, electroplating, painting, printing, etc.)!

At present, it is the most widely used in China. The main materials are ABS, PMMA and other resins, and the metals are mainly aluminum alloy and copper alloy.

Advantages of CNC prototype:

Good toughness, high strength, high tensile strength, moderate cost, and wide range of material options.

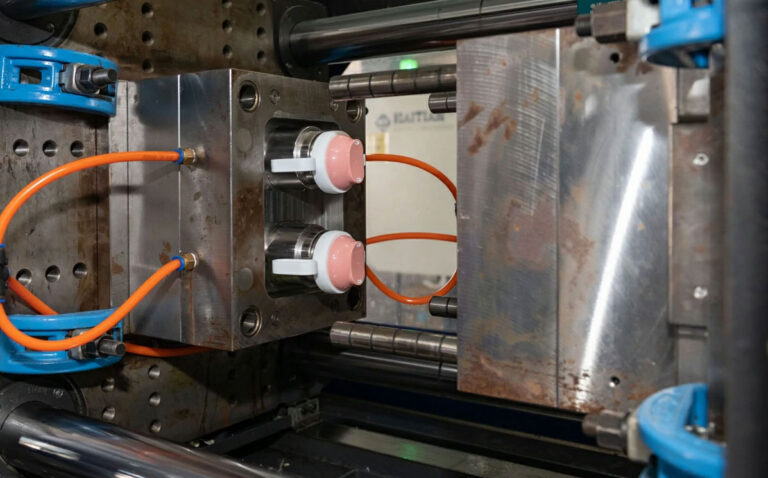

Vacuum molding

The mold replication is to use the existing sample to make a simple silicone mold under vacuum state, and then use other materials to cast under vacuum state, and then replicate the product that is the same as the original sample.

This method is suitable when customers require several or dozens of sets, and can greatly reduce costs.

However, the product samples produced by vacuum molding may be reduced in size by a certain percentage, and the cost is generally lower than that of CNC.

The vacuum molding technology can be used in two ways:

- Produce small batches of product samples;

- Change the material; the sample that is not easy to process can be changed to a material that is easy to process later through re-molding, or the ABS material can be changed to a material with special requirements (such as: transparent, high temperature resistant, high strength, or rubber properties, etc.).