Intro

An engineer working in the cutting field said:

(1) Fiber lasers are now the mainstream in the market, and carbon dioxide lasers are gradually being phased out due to their high energy consumption. However, they still have a market in the non-metallic field.

(2) Since the domestic production of lasers, the price of fiber optic equipment has dropped significantly in the medium and low power ranges.

(3) Among the other cutting methods except laser, the market demand for plasma and wire cutting is relatively large, but wire cutting is mostly used in the mold industry, while plasma is more in demand for thick plates or when the precision requirements are not high. Water jet cutting is no longer common in the metal industry, but is very common in the non-metal field.

(4) In the future development, laser cutting will definitely dominate the field of thin and medium-sized metal plates, and non-metal cutting will also occupy a considerable part of the market.

Let’s analyze these cutting techniques.

Laser cutting

Laser cutting uses a focused, high-power density laser beam to illuminate a workpiece, causing it to rapidly melt, vaporize, ablate, or reach its ignition point. Simultaneously, a high-speed airflow coaxial with the beam blows away the molten material, thereby separating the workpiece. Currently, CO2 pulsed lasers are commonly used, and laser cutting is a form of thermal cutting.

Waterjet cutting

Waterjet cutting, also known as waterjet, is a high-pressure water jet cutting technology that uses a high-pressure water jet to cut. Under computer control, it can sculpt workpieces to any desired degree and is minimally affected by the material’s texture. Waterjet cutting can be performed in two ways: sandless cutting and abrasive cutting.

Plasma cutting

Plasma arc cutting is a processing method that uses the heat of a high-temperature plasma arc to locally melt (and evaporate) the metal at the workpiece incision, and uses the momentum of high-speed plasma to remove the molten metal to form an incision.

Wire Cutting

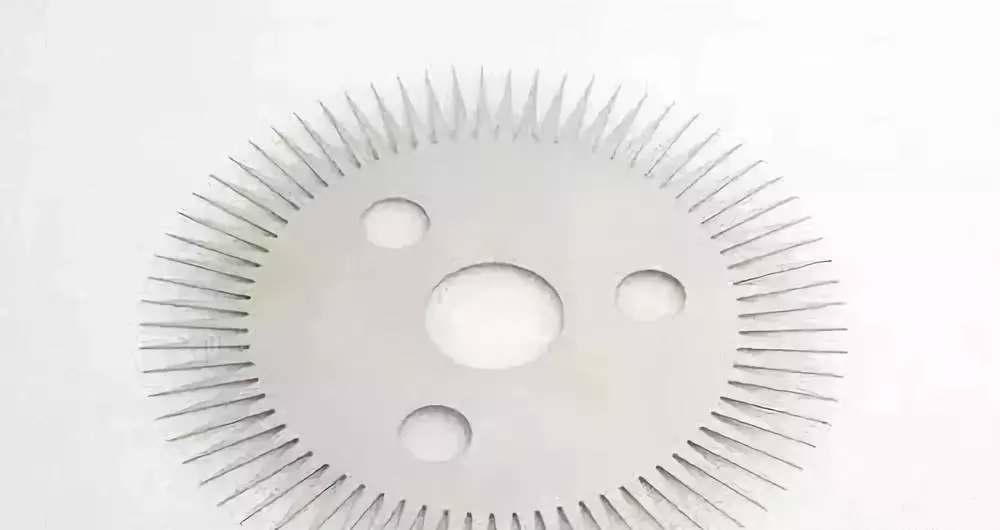

Wire EDM (Wire Electrical Discharge Machining) falls under the category of electrical machining. Wire EDM (Wire Cut Electrical Discharge Machining) is sometimes also called wire cutting. Wire cutting can be categorized as fast-wire, medium-wire, and slow-wire.

Fast-wire EDM uses a wire speed of 6 to 12 m/s, with the electrode wire moving back and forth at high speed, resulting in poor cutting accuracy.

Medium-wire EDM is a recently developed process that builds on fast-wire EDM with variable-frequency, multiple-cutting capabilities.

Slow-wire EDM uses a wire speed of 0.2 m/s, with the electrode wire moving in a single direction at low speed, resulting in very high cutting accuracy.

1, Comparison of application scope

Laser cutting machines have a wide range of applications, and can cut both metal and non-metal materials. Non-metal materials such as cloth and leather can be cut with a CO2 laser cutting machine, while metal materials can be cut with a fiber laser cutting machine. The plate deformation is minimal.

Waterjet cutting is a cold cutting method with no thermal deformation. The cut surface quality is good and no secondary processing is required. However, secondary processing is easy to perform if necessary. Waterjet cutting can drill and cut any material with high cutting speed and flexible processing size.

Plasma cutting machines can be used to cut various metal materials such as stainless steel, aluminum, copper, cast iron, carbon steel, etc. Plasma cutting has obvious thermal effects, low precision, and the cut surface is not easy to perform secondary processing.

Wire cutting can only cut conductive materials, and cutting coolant is required during the cutting process. Therefore, materials such as paper and leather that are non-conductive, afraid of water, and afraid of being contaminated by cutting coolant cannot be cut.

2, Cutting thickness comparison

Laser cutting of carbon steel in industrial applications is generally limited to thicknesses under 20mm, with cutting speeds generally below 40mm. Industrial applications of stainless steel generally involve cutting thicknesses under 16mm, with cutting speeds generally below 25mm. Furthermore, cutting speeds decrease significantly as workpiece thickness increases.

Breakthrough in 30mm fiber laser cutting of sheet metal

The thickness of water jet cutting can be very thick, 0.8-100mm, or even thicker materials.

Plasma cutting thickness is 0-120mm, and the best cutting quality range is around 20mm thickness, which is the most cost-effective plasma system.

The thickness of wire cutting is generally 40 to 60 mm, and the thickest can reach 600 mm.

3, Cutting speed comparison

A 1200W laser can cut a 2mm thick mild steel plate at a speed of 600cm/min; a 5mm thick polypropylene plate at a speed of 1200cm/min. Wire EDM generally achieves a cutting efficiency of 20-60 square millimeters/min, with a maximum of 300 square millimeters/min. Clearly, laser cutting is faster and can be used for mass production.

The speed of water cutting is quite slow and not suitable for mass production.

Plasma cutting has a slow cutting speed and relatively low precision. It is more suitable for cutting thick plates, but the end face has a slope.

For metal processing, wire cutting has higher precision, but the speed is very slow. Sometimes other methods are needed to punch holes and thread wires before cutting, and the cutting size is greatly limited.

4, Cutting accuracy comparison

Laser cutting has narrow incisions, with both sides of the cut parallel and perpendicular to the surface. The dimensional accuracy of the cut parts can reach ±0.2mm.

Plasma can reach within 1mm.

Water cutting will not produce thermal deformation, and the accuracy is ±0.1mm. If a dynamic water cutting machine is used, the cutting accuracy can be improved to ±0.02mm, eliminating the cutting slope.

The wire cutting processing accuracy is generally ±0.01~±0.02mm, and can reach up to ±0.004mm.

5, Slit width comparison

Laser cutting is more precise than plasma cutting, and the cutting gap is smaller, about 0.5mm.

The kerf of plasma cutting is larger than that of laser cutting, about 1-2 mm.

The kerf of water jet cutting is about 10% larger than the diameter of the cutter tube, generally 0.8-1.2mm. As the diameter of the sander tube expands, the kerf becomes larger.

The kerf width of wire cutting is the smallest, generally around 0.1-0.2mm.

6, Comparison of cutting surface quality

The surface roughness of laser cutting is not as good as that of water jet cutting, and the thicker the material, the more obvious it is.

Waterjet cutting does not change the texture of the material around the cutting seam (laser is a thermal cutting method that changes the texture around the cutting area).

Comparison of production input costs

1) Laser cutting machines vary in price depending on their purpose. Cheaper models, such as CO2 laser cutting machines, cost only 20,000 to 30,000 yuan, while more expensive models, such as 1000W fiber laser cutting machines, now cost over 1 million yuan.

Laser cutting requires no consumables, but the equipment investment cost is the highest of all cutting methods, and it’s not just a little bit higher. Operation and maintenance costs are also quite high.

2) Plasma cutting machines are much cheaper than laser cutting machines. The price varies depending on the power, brand, etc. of the plasma cutting machine, and the cost of use is relatively high. Basically, as long as the conductive material can be cut, it can be used.

3) The cost of water jet cutting equipment is second only to laser cutting. It has high energy consumption and high maintenance costs. The cutting speed is not as fast as plasma because all abrasives are disposable and are discharged into nature after one use. Therefore, the environmental pollution it causes is also relatively serious.

4) Wire EDM generally costs tens of thousands of yuan. However, wire EDM requires consumables, such as molybdenum wire and cutting coolant. Two types of wire are commonly used for wire EDM: molybdenum wire (molybdenum is precious), used in fast-moving wire-cutting equipment. Its advantage is that it can be reused multiple times; copper wire (much cheaper than molybdenum wire anyway) is used in slow-moving wire-cutting equipment.

Its disadvantage is that copper wire is only usable once. Furthermore, fast-moving wire-cutting equipment is significantly cheaper than slow-moving wire-cutting equipment; the price of one slow-moving wire-cutting equipment is equivalent to the price of five or six fast-moving wire-cutting equipment.