Introduction

As the market demand for machining increases, the technical precision of machining also increases, and the types of machine tools become more and more numerous.

According to the processing methods and tools used, the country has divided machine tools into 11 categories: lathes, drilling machines, boring machines, grinding machines, gear processing machines, thread processing machines, milling machines, planers, drawing machines, sawing machines and other machine tools.

Among them, the seven commonly used categories are boring machines, grinders, lathes, planers, milling machines, drilling machines, and gear processing machines.

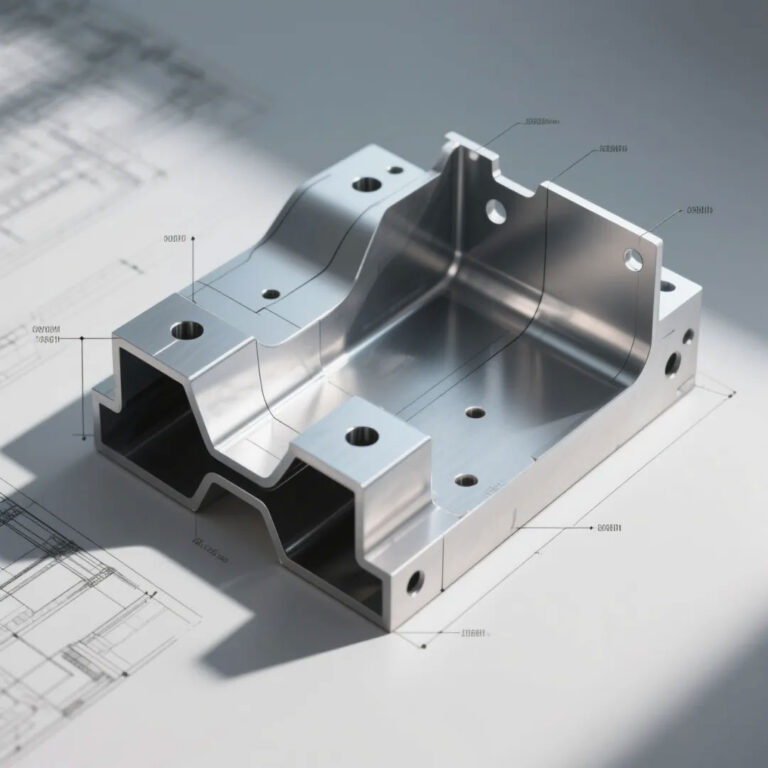

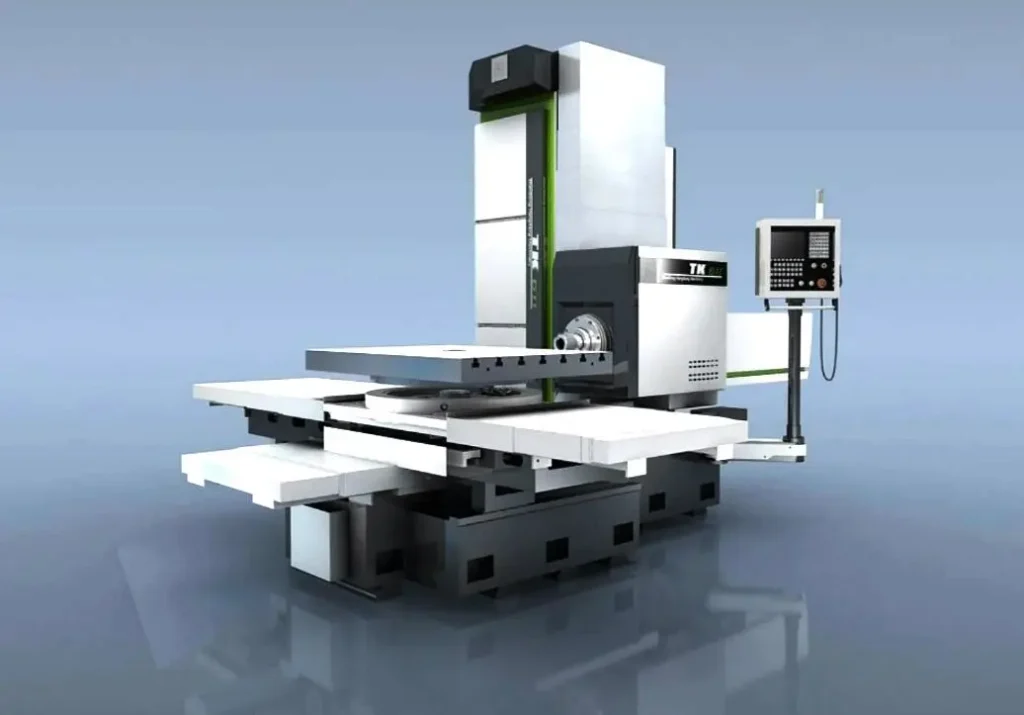

Boring Machine

Boring machines are suitable for plane milling and hole processing of single-piece or small-batch produced parts in machining workshops. The end of the spindle box is designed with a flat rotary disk radial tool holder, which can accurately bore larger holes and planes.

Boring machines are divided into CNC boring machines and CNC jig boring machines, both of which are available in vertical and horizontal configurations. Boring machines use point and linear control and are suitable for machining box parts, requiring manual tool changes. Jig boring machines also use point and linear control and are suitable for machining box parts with high hole spacing requirements, also requiring manual tool changes.

Grinding Machine

Machine tools that use abrasive tools (grinding wheels, abrasive belts, oilstones or abrasives, etc.) as tools to cut the surface of workpieces are collectively called grinders.

According to the nature of the process, it is divided into surface grinders, internal and external cylindrical grinders, universal grinders, centerless grinders, and special grinders. The control methods are point, straight line, and contour.

It is mainly used for rough and fine grinding of flat surfaces, mirror grinding, profile grinding after grinding wheel modification; automatic correction of grinding wheels, etc.; centerless grinders can grind directly without pre-turning and centerless profile grinding; special grinding machines include screw grinders, spline grinders, crankshaft grinders, camshaft grinders, etc.

Since grinding can easily achieve high processing accuracy and good surface quality, grinding machines are mainly used for finishing parts, especially finishing of hardened steel parts and high-hardness special materials.

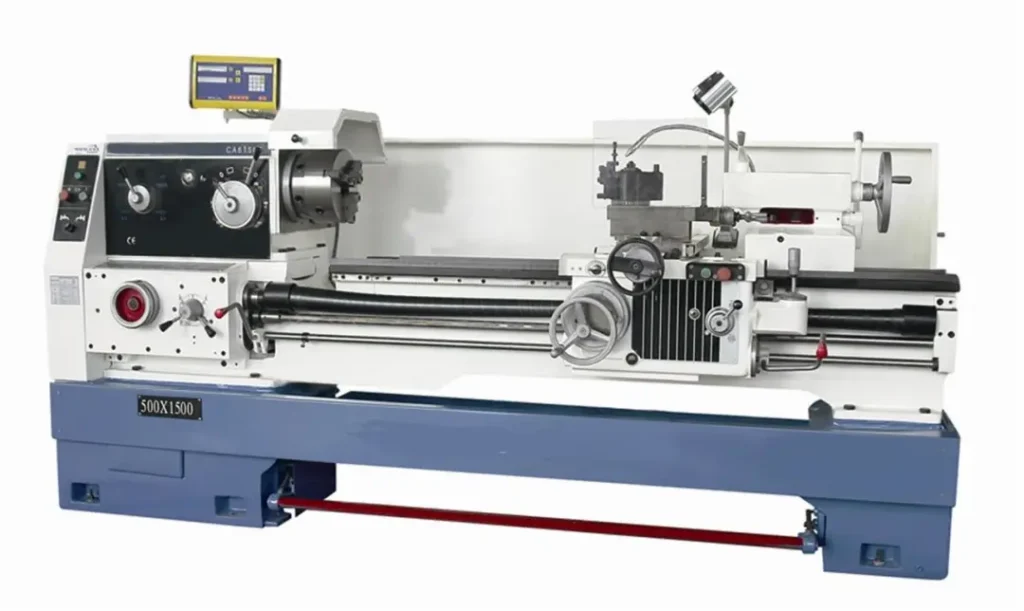

Lathe

Lathes are mainly used to process various rotating surfaces and end faces of rotating bodies. They are mainly used to process various rotating surfaces and end faces of rotating bodies. The equipment can be divided into horizontal and vertical types.

Among them, the chuck horizontal lathe has point and straight line control mode, which is used for processing small disc parts and adopts square tool holder or turret; the top horizontal lathe has contour control mode, which is used for processing disc and shaft parts. The bed can be horizontal, vertical or inclined, and adopts square tool holder or rotary tool magazine.

The vertical CNC lathe adopts contour control mode, is used for processing large continuous control disk parts, and adopts turret tool holder.

Planer

Planers are mainly used to process various planes (such as horizontal planes, vertical planes and inclined planes and various grooves, such as T-slots, dovetail grooves, V-slots, etc.) and straight line forming surfaces.

If equipped with a profiling device, it can also process spatial curved surfaces, such as turbine impellers, spiral grooves, etc. The tool structure of this type of machine tool is simple, and no cutting is done during the return stroke, so the productivity is low and it is generally used for single-piece and small-batch production.

Milling Machine

A widely used machine tool that can process planes (horizontal and vertical surfaces), grooves (keyways, T-slots, dovetail slots, etc.), toothed parts (gears, spline shafts, sprockets, spiral surfaces (threads, spiral grooves) and various curved surfaces. It can also be used for machining the surface of rotating bodies, internal holes and cutting.

When a milling machine is in operation, the workpiece is mounted on a workbench or an accessory such as a dividing head. The main motion of the milling cutter is rotation, supplemented by the feed motion of the workbench or milling head. The workpiece can obtain the desired surface finish. Due to the multi-tool intermittent cutting, the milling machine has a high productivity.

Milling machines are divided into vertical and gantry types. Vertical CNC milling machines have control modes such as point position, line, contour (multi-axis linkage), milling, form milling (also capable of drilling and tapping), and manual tool change.

The control modes of gantry CNC milling machines include point position, straight line, and contour (multi-axis linkage). They are used to process large and complex-shaped parts and require manual tool change.

In addition, there is a CNC copy milling machine on the market, which is also divided into vertical and horizontal types. The control method is contour (multi-axis linkage), which is used for processing concave and convex molds and manual tool change.

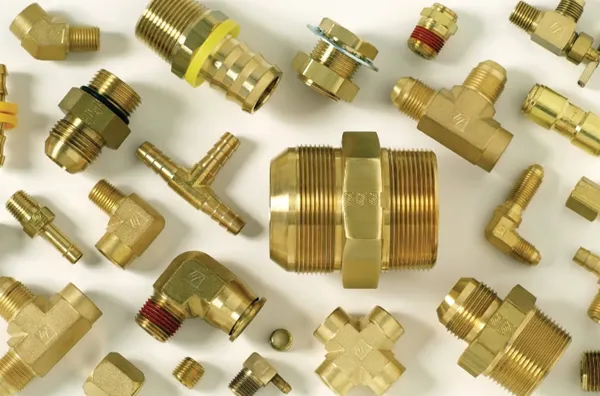

Drilling Machine

A drilling machine is a versatile machine tool with a wide range of applications. It can perform various operations, including drilling, reaming, countersinking, and tapping. A radial drilling machine equipped with process equipment can also perform boring operations. A bench drill equipped with a universal worktable can also mill keyways.

The drilling machine is divided into single and double work tables, with point and linear control modes, and can drill, ream holes, and tap threads; two fixed work tables, one for processing and the other for loading and unloading parts, and a linear tool magazine.

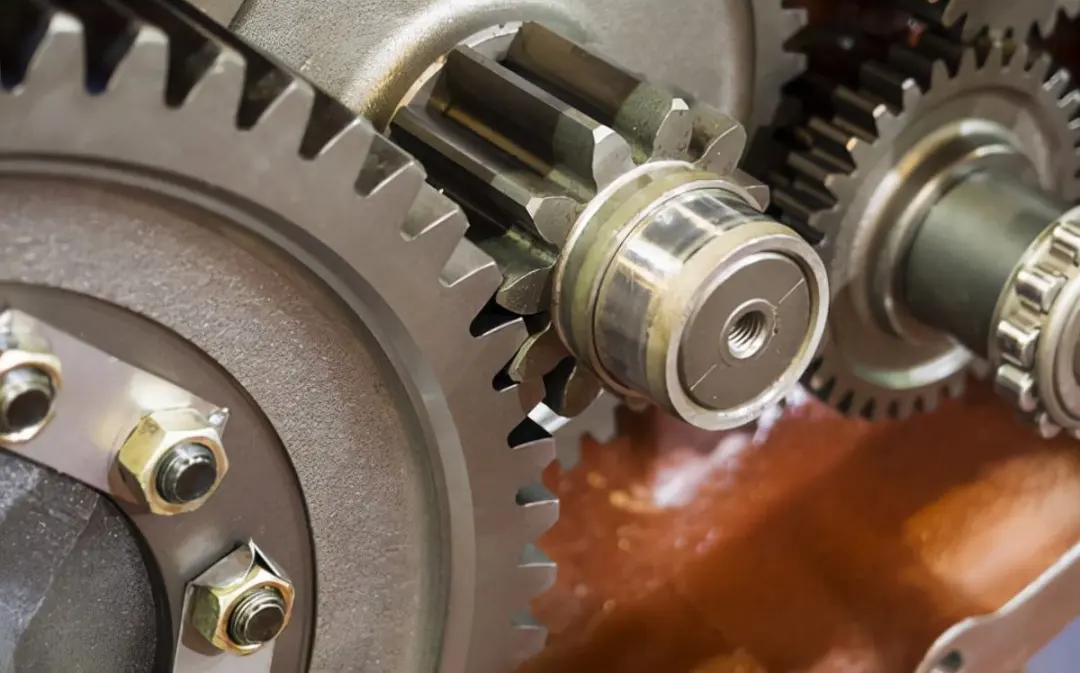

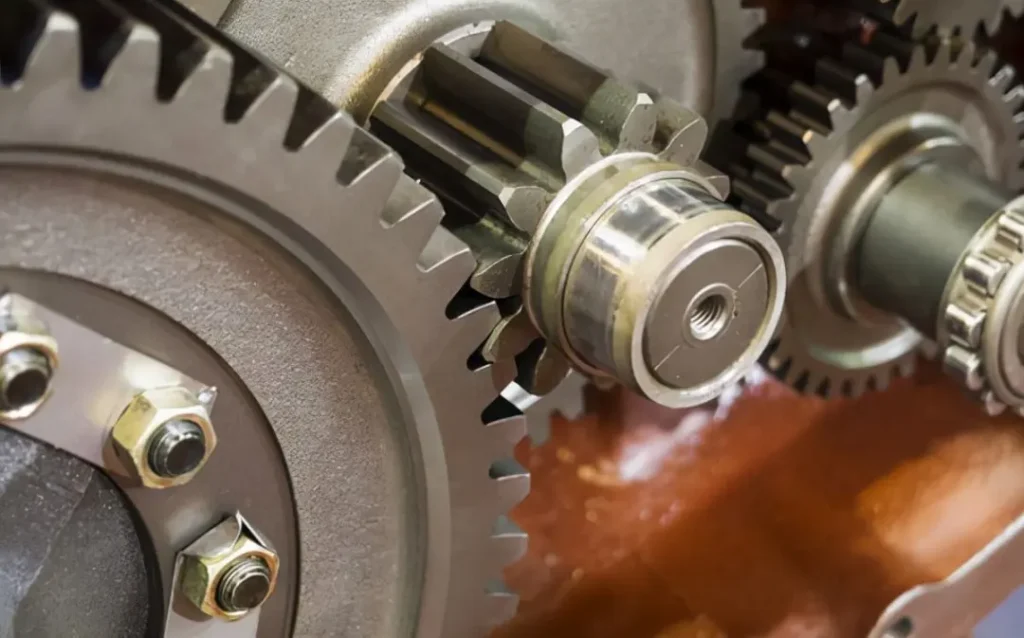

Gear Cutting Machine

Gear cutting machines are used to machine the teeth of various cylindrical gears, bevel gears, and other toothed parts. They are controlled by linear motion and generate the tooth profile. They are categorized by gear hobbing, gear shaping, and gear grinding, depending on the processing method.

Gear Hobbing Machine

Gear machines can cut spur and helical gears, as well as worm gears and sprockets. They use hobs to generate spur, helical, and herringbone gears, as well as worm gears. Using a special hob, this machine can also process workpieces with special tooth shapes, such as splines and sprockets.

The processing accuracy of ordinary gear hobbing machines is 7~6 levels (JB179-83), and that of high-precision gear machines is 4~3 levels. The maximum processing diameter is 15m.

Gear Shaping Machine

It is a gear processing machine that uses a gear shaping cutter to machine internal and external spur and helical gears and other toothed parts using the generating method. During gear shaping, the gear shaping cutter performs an up and down reciprocating cutting motion while rolling relative to the workpiece.

Gear shapers are primarily used for machining multi-link gears and internal gears. With the addition of accessories, they can also machine racks. Using specialized tools, gear shapers can also machine non-circular and incomplete gears, as well as internal and external shaped surfaces such as square and hexagonal holes and keyed shafts. Machining accuracy can reach levels 7-5 (JB179-83), and the maximum workpiece diameter can reach 12m.

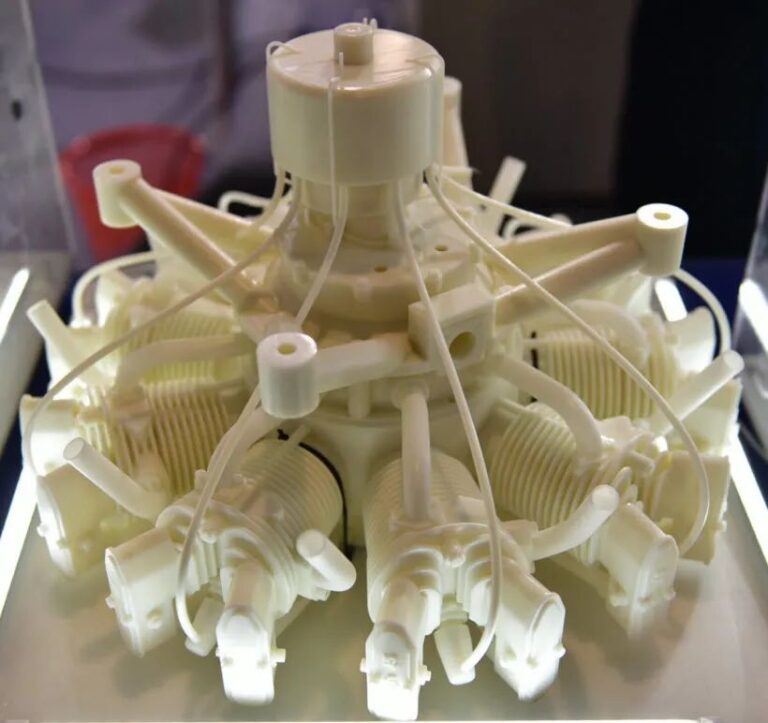

Gear Grinding Machine

Gear processing is the use of grinding wheels as grinding tools to process cylindrical gears or certain gears (helical gears, bevel gears, etc.) to process the tooth surfaces of the tool.

Gear processing machine tools come in a wide variety of types and specifications, including small machine tools for processing gears with a diameter of a few millimeters, large machine tools for processing gears with a diameter of more than ten meters, high-efficiency machine tools for mass production, and high-precision machine tools for processing precision gears.

Gear processing machines are widely used in various machinery manufacturing industries such as automobiles, tractors, machine tools, engineering machinery, mining machinery, metallurgical machinery, petroleum, instrumentation, aircraft and spacecraft.