Today, the editor has compiled some knowledge about surface treatment technology for prototyping, hoping it will be helpful to you.

1.Screen printing

Screen printing involves stretching silk, synthetic fiber, or metal mesh over a screen frame, using hand-engraved lacquer or photochemical platemaking to create the screen plate. Modern screen printing technology utilizes photosensitive materials through a photoengraving process to create the screen plate (the holes in the image area of the screen plate are open, while the holes in the non-image area are blocked ) . During printing, a squeegee presses the ink through the mesh holes in the image area and transfers it to the substrate, creating an image that matches the original.

Screen printing equipment is simple and easy to operate, making printing and platemaking simple, cost-effective, and highly adaptable. Screen printing has a wide range of applications, with common printed products including: color paintings, posters, business cards, book covers, product labels, and printed textiles.

2.Pad printing

Pad printing is a specialty printing method. It’s a very simple technique, employing a steel (or copper, or thermoplastic) gravure plate and a curved silicone rubber pad. Ink from the gravure plate is applied to the pad head, which is then pressed against the desired surface to create text, images, and more. For example, this method is used to print text and images on mobile phones, as well as computer keyboards, instruments, and many other electronic products.

3.Curved surface printing

Curved surface printing involves first placing ink into an intaglio plate engraved with text or a pattern, then copying the text or pattern onto a curved surface, which is then used to transfer the text or pattern to the surface of the molded product. Finally, the ink is cured by heat treatment or ultraviolet light exposure.

4.Etching printing

The etching process involves printing a layer of uneven, translucent ink onto smooth substrates, such as gold and silver cardstock. The ink is then cured with a specialized ultraviolet (UV) light source to create an artistic effect similar to etching or frosting on metal surfaces. Etching printing is one of the world’s newest printing technologies.

Etched prints possess an immense allure, imbued with a sense of uniqueness, novelty, three-dimensionality, and artistic quality. The most significant characteristic of etching is that it does not obscure the original color of the substrate, resulting in a delicate, translucent aesthetic.

5.Lithographic process

Because the image and non-image areas of lithographic printing are on the same plane, during printing, the principle of oil-water separation is used to ensure that the ink can distinguish between the image and non-image areas of the printing plate. First, the water supply system of the printing plate component supplies water to the non-image area of the printing plate, thereby protecting the non-image area from the ink.

Then, the ink supply system of the printing unit supplies ink to the printing plate. Because the non-image area of the printing plate is protected by water, the ink is only supplied to the image area of the printing plate.

Finally, the ink on the printing plate is transferred to the latex. Then, the pressure between the rubber roller and the impression cylinder transfers the ink from the latex to the substrate, completing the printing. Therefore, lithographic printing is an indirect printing method.

6.Lettering

Hot stamping, also known as “gilding”, has a long history in my country. It refers to the process of hot stamping text and patterns with materials such as colored foil on the cover of a hardcover book, or embossing the title or pattern with various convex and concave shapes using heat pressing.

7.Anodized aluminum hot stamping

Hot stamping is a decorative printing process that uses the principle of heat transfer to transfer the aluminum layer of anodized aluminum to the substrate surface. At a certain temperature, text and patterns are transferred to the surface of plastic products.

Its advantage is that this method does not require surface preparation and can be used with simple equipment to produce color printing. It can also produce products with metallic lusters such as gold and silver.

8.Water transfer printing technology

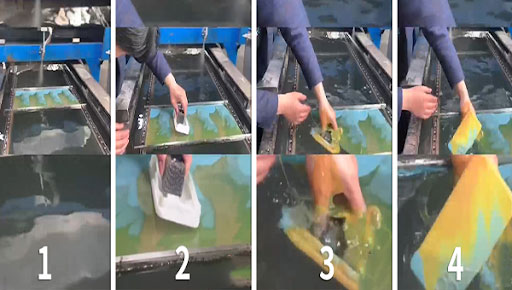

Water transfer printing uses water pressure to hydrolyze a colored transfer paper or plastic film. The process includes making the water transfer paper, soaking the paper, transferring the pattern, drying, and finally the finished product.

9.IMD

In-mold decoration ( IMD ) technology can be categorized by its production and processing methods, including IMR, IML, and IMF. IMR (In-Mold Roller) is an in-mold decoration technology that transfers ink from a film to the product’s exterior surface through injection molding, then removes the film during the mold opening process.

ML (In-Mold Labeling) involves manually or robotically inserting a printed, cut-to-size label into a mold and then attaching it to the finished product’s exterior through injection molding.

10.Mechanical polishing

Mechanical polishing is a polishing method that achieves a smooth surface by removing raised areas through cutting and plastic deformation of the material surface. Typically, tools such as oilstones, wool wheels, and sandpaper are used. While manual labor is the primary method, tools such as turntables may be used for specialized parts, such as rotating surfaces.

For high-quality surface finishes, ultra-fine polishing can be employed. Ultra-fine polishing utilizes a specially designed grinding tool, which is pressed against the workpiece surface while rotating at high speed in a working fluid containing an abrasive. This technique can achieve surface roughnesses of Ra 0.008μm, the highest among all polishing methods. This method is often used for optical lens molds.

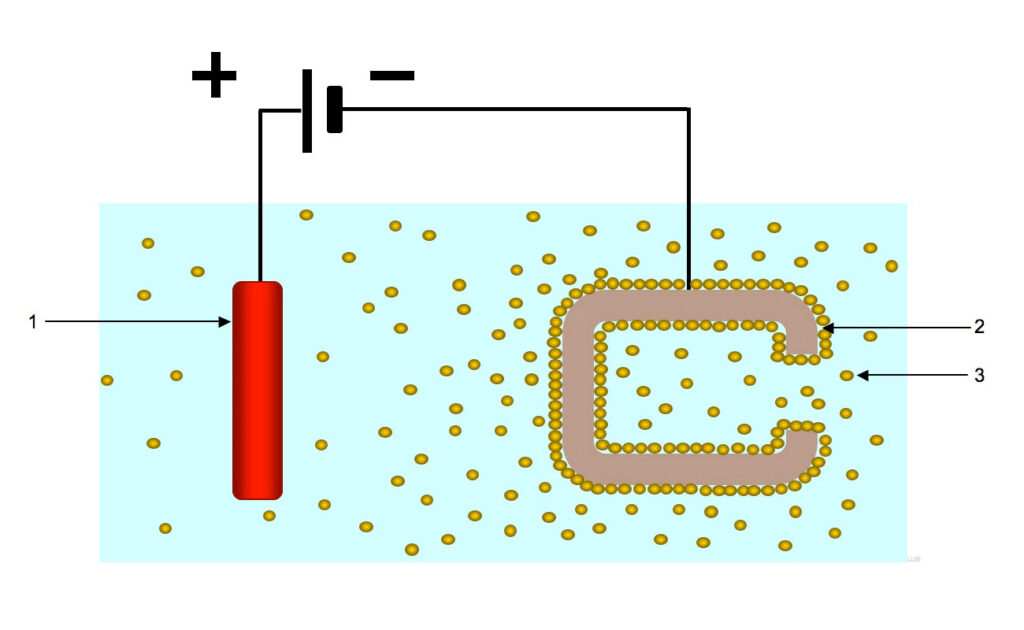

11.Electrolytic polishing

Electrolytic polishing uses the workpiece as the anode and the insoluble metal as the cathode. Both electrodes are immersed in the electrolytic tank at the same time, and a DC ionization reaction is passed through to produce selective anodic dissolution, thereby achieving the effect of removing fine burrs on the workpiece surface and increasing the brightness.

12.Chemical polishing

Chemical polishing is a method that relies on the selective dissolution of uneven areas on the sample surface by chemical reagents to eliminate wear marks and etch and level the surface.

13.Etching

Etching is a technique that removes material through chemical reactions or physical impact. Etching techniques can be categorized as wet etching and dry etching .

Etching, also commonly referred to as photochemical etching, involves removing the protective film in the area to be etched after exposure to light and development. During etching, the area is exposed to a chemical solution, which dissolves and corrodes the material, creating a concave, convex, or hollowed-out effect.

14.3D diamond carving

3D diamond engraving is the process of using diamond cutting tools to process metal surfaces, leaving traces of the diamond cutting tools rotating on the metal surface.

This process can be applied not only to the finishing of general products, but also to the field of mold manufacturing.

15.High light oxidation

High-gloss oxidation adopts anodizing and mirror polishing technology to give the product surface a high-gloss effect.

16.Electrophoretic coating technology

Electrophoretic coating technology uses an applied electric field to direct the migration of pigments and resin particles suspended in an electrophoretic fluid, depositing them on the substrate surface at one of the electrodes. Electrophoretic coating is a specialized film-forming method developed over the past 30 years.

18.Powder coating

Powder coating utilizes the action of high-voltage electrodes. Powder particles absorb negative ions when passing through this ion cloud and become negatively charged. Powder coating can reduce environmental pollution, effectively lower costs, and increase production capacity.

19.Optical coating technology

Optical coating technology refers to the process of depositing one or more layers of thin metal (or dielectric) films on the surface of optical components.

The goal is to reduce or increase light reflection, beam splitting, color separation, filtering, and polarization. The most common method is to deposit thin films on glass substrates using vacuum sputtering.

20.Nanoimprint technology

Nanoimprint technology uses mechanical means to transfer patterns. It has the technical advantages of ultra-high resolution, easy mass production, low cost and high consistency. It is considered to be a processing method that is expected to replace existing photolithography technology.

21.Hot stamping technology

Hot stamping technology is a printing decoration process that transfers the aluminum layer in electroplated aluminum to the surface of the substrate, using the principle of heat pressure transfer to create a special metallic effect.

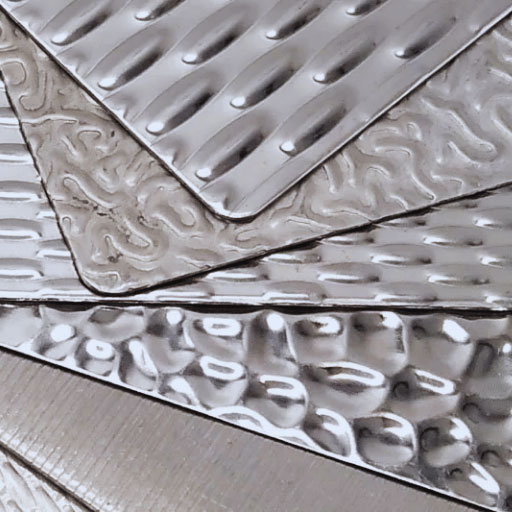

22.Embossing process

Metal sheets are rolled using patterned work rolls, typically treated with an etchant. The depth of the embossing varies depending on the pattern, but can range from 0.02mm to 0.03mm.

Aluminum embossing involves rolling and other processes on aluminum sheet, creating a variety of surface patterns. Embossed aluminum sheet is primarily used in packaging, integrated ceilings, and architectural curtain walls.

23.Vinyl chloride (VCM) film-faced board process

VCM laminates are laminated with a PVC film, creating a secure bond between the metal surface and the metal. Also known as PVC laminates or PET/PVC laminated colored steel sheets, VCM offers excellent workability, decorative surface properties, corrosion resistance, and scratch resistance. The surface film of the laminate is printable, allowing for a variety of color, texture, and other effects.

24.PCM pre-coated board process

Pre-coating refers to the process of spraying paint onto metal surfaces. Pre-coated panels offer a rich palette of colors, high production efficiency, fast turnover, and are environmentally friendly and pollution-free.

Applications have expanded beyond Venetian blinds to include building exteriors, interior decoration, transportation, and home appliance exteriors.

25.Surface hardening technology

This refers to a process that uses appropriate methods to harden the surface of a part while maintaining its core toughness. PMMA is an organic material with a relatively low hardness, making it more susceptible to scratches.

Therefore, the surface must be hardened. This process is called PMMA surface hardening. This type of sheet is commonly used in various high-contact display panels, such as mobile phones, display screens, and instrument panels. Because hardened acrylic sheets are not susceptible to scratching, surface hardening can increase the hardness of acrylic sheets from H to over 4H.

26.Galvanizing

It refers to the surface treatment technology of plating a layer of zinc on the surface of metal, alloy or other materials for the purpose of beauty, rust prevention, etc.

27.Powder coating

Powder coating is sprayed onto the surface of the workpiece using powder spraying equipment (electrostatic spraying machine). Under the action of static electricity, the powder will be evenly adsorbed on the surface of the workpiece to form a powdery coating; the powdery coating is baked and leveled and solidified at high temperature to become the final coating with different effects (different types of powder coating effects).

28.Microarc oxidation (MAO)

Also known as microplasma oxidation ( MPO ), it is a process that uses a combination of electrolyte and corresponding electrical parameters to grow a ceramic film mainly composed of matrix metal oxide on the surface of aluminum, magnesium, titanium and their alloys by relying on the instantaneous high temperature and high pressure generated by arc discharge.

29.Brushed Metal

The wire drawing process involves repeatedly scraping aluminum sheets with sandpaper to create lines. The process consists of three main steps: degreasing, sanding, and washing. During the wire drawing process, a special coating technology applied after anodizing creates a film containing the metal’s components on the metal surface, clearly revealing every tiny trace and giving the matte metal a fine, hair-like sheen.

30.Blueing

The entire body is filled with colored glaze, and then fired in a blast furnace with a temperature of about 800 degrees Celsius. The colored glaze melts from a sandy solid into a liquid, and after cooling, it becomes a gorgeous colored glaze fixed on the body.

At this time, the colored glaze is lower than the height of the copper wire, so it has to be filled with colored glaze again and then sintered. Generally, it needs to be done four or five times in a row until the pattern is filled to the same level as the filigree pattern.

31.Frosted

Frosting is the process of making a smooth surface less smooth, creating a diffuse reflection of light. In chemistry, frosting involves mechanically or manually grinding glass with abrasives such as corundum, silica sand, and pomegranate powder to create a uniformly rough surface. Alternatively, the surface of glass or other objects can be processed with a hydrofluoric acid solution, resulting in a product called frosted glass.

32.Thermal transfer

Thermal transfer printing is an emerging printing process introduced from abroad. It consists of two main methods: film transfer printing and transfer processing. Film transfer printing utilizes dot printing (resolution up to 300dpi), pre-printing the pattern onto the film surface.

The resulting printed pattern is rich in layers, vibrant in color, and ever-changing, with minimal color variation and excellent reproducibility. It can meet the designer’s desired effect and is suitable for mass production.

33.Laser Engraving

Laser engraving, also known as laser marking, is a surface treatment process that uses optical principles. It uses a laser beam to create a permanent mark on a surface or inside a transparent material. Laser beams can produce both chemical and physical effects on materials. When the material absorbs the laser light instantaneously, a physical or chemical reaction occurs, creating a mark or displaying a pattern or text.

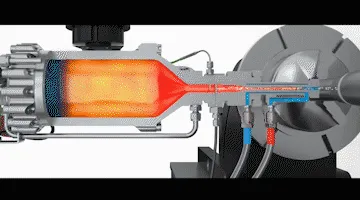

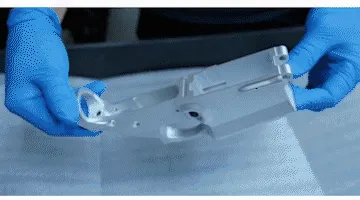

34.PVD

PVD, short for Physical Vapor Deposition, involves using low-voltage, high-current arc discharge technology under vacuum conditions to vaporize a target material and ionize both the evaporated material and the gas. The electric field accelerates the vaporized material and its reaction products, depositing them on the workpiece. Thin films produced by PVD exhibit high hardness, low friction, excellent wear resistance, and chemical stability.

35.Electroplating

Electroplating is the process of depositing a thin layer of another metal or alloy onto a metal surface using electrolysis. This process involves depositing a thin layer of metal onto the surface of a metal or other material, thereby preventing oxidation (such as rust), improving wear resistance, electrical conductivity, reflectivity, corrosion resistance (such as copper sulfate ) , and enhancing aesthetics. Many coins also have an electroplated outer layer.

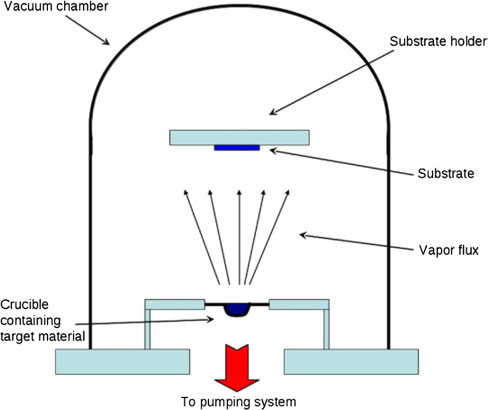

36.Vacuum evaporation

Evaporation is a process that uses a specific heating evaporation method under vacuum conditions to evaporate the coating material and vaporize it. The particles fly to the substrate surface and condense into a film. Evaporation is an older and more widely used vapor deposition technology.

37.Water electroplating technology

It is a process of plating a layer of metal on the surface of a substrate using the principle of electrolysis. Since the production process is usually carried out in an electrolyte, it is called “water electroplating.” The introduction of the electroplated layer can enhance the corrosion resistance and hardness of the substrate, prevent wear, improve conductivity, lubricity, heat resistance, and surface aesthetics.

It is a technology that uses the principle of an electrolytic cell to deposit a metal coating on mechanical products that has good adhesion but different performance from the base material. The electroplated layer is more uniform than the hot-dip layer and is generally thinner, ranging from a few microns to tens of microns. Through electroplating, decorative protective and various functional surface layers can be obtained on mechanical products, and workpieces that have been worn or processed incorrectly can also be repaired.

38.Nano-spraying technology

Direct spraying creates a colorful, mirror-like, high-gloss finish on the surface. It offers excellent adhesion, impact resistance, corrosion resistance, weather resistance, wear resistance, abrasion resistance, and rust resistance.

It can also be used for surface decoration and protection in other industries. This advanced surface treatment technology is simple, environmentally friendly, and widely applicable.

39.Calendering

Also known as calendering, it is the final step in heavy leather finishing. This finishing process utilizes the plasticity of fibers under mixed heat conditions to flatten or create fine, parallel, diagonal lines on the surface of the fabric, enhancing its luster.

The material is fed in, heated and melted, then formed into a sheet or film, cooled, and rolled up. The most commonly used calendered material is polyvinyl chloride.

40.Flat screen printing

The printing die is a polyester or nylon screen (or screen) with a hollowed-out pattern, mounted on a square frame. The patterned areas of the screen allow the color paste to pass through, while the unpatterned areas are sealed with a polymer film.

During printing, the screen is pressed against the fabric, and the color paste is applied to the screen. A scraper is used to apply the paste back and forth, forcing it through the pattern and onto the fabric surface. Flat screen printing has low production efficiency, but it offers wide adaptability and flexibility, making it suitable for small-batch, high-variety production.

41.Spraying

A coating method that uses a spray gun or disc atomizer to disperse the material into uniform, fine droplets using pressure or centrifugal force, and then applies it to the surface of the object. This method can be categorized as air spray, airless spray, electrostatic spray, and various derivatives of these basic spray methods, such as high-flow, low-pressure atomization spray, thermal spray, automatic spray, and multi-group spray.

42.Spraying technology – PU paint

Spraying is a coating method that uses a spray gun or butterfly atomizer to disperse the paint into uniform, fine droplets using pressure or centrifugal force, and then applies it to the surface of the object. PU paint is a general term for all polyurethane coatings.

Its film formation method is natural, and no special process is required. PU paint spraying is to spray a layer of PU paint on the surface of the workpiece.

43.PET film UV transfer

By utilizing the non-stick properties of UV transfer glue and metal, the ultra-thin key effects of various mobile phones are transferred to PET sheets through the UV transfer process, thereby making ultra-thin keys and key types with effects including CD texture, vertical brushed, matte, and glossy texture.

44.Film Forming

The film forming process involves heating and softening the film, then applying external forces to shape and cool it, creating a 3D film.

This process is primarily divided into two types: hot pressing and forming. The pressing process softens the film using mold temperature, then uses mold pressure to shape the softened film within the hot pressing mold cavity, where it cools and sets the shape.

45.Glue filling process

By mixing two kinds of glue, the product surface is coated to make the product surface present a crystal clear effect. The main function is to increase the surface effect, full plastic dripping, partial plastic dripping, font shape glue effect, filling effect, partial filling, weight controlled filling and other different effects.

46.Laser texturing

High-energy-density lasers react with steel surfaces to create snakeskin, etched, pear-shaped, or other textures. This enhances product aesthetics, overcomes the drawbacks of printed and painted surfaces that can easily wear off, and meets visual requirements.

While mirror-like surfaces are easily scratched, dusty, and fingerprinted, flaws, hairlines, and ripples created during the forming process are easily visible on the product’s smooth surface, decorative patterns such as leather, orange peel, wood, raindrop, and matte finishes can conceal surface imperfections created during the forming process, enhancing the product’s aesthetics and satisfying visual needs.

47.Sandblasting

Compressed air is used as the power to form a high-speed jet beam to spray the material (copper ore sand, quartz sand, corundum, iron sand, Hainan sand) at high speed onto the surface of the workpiece to be processed, so that the appearance or shape of the outer surface of the workpiece changes.

Due to the impact and cutting effect of the abrasive on the workpiece surface, the surface of the workpiece obtains a certain degree of cleanliness and different roughness, and the mechanical properties of the workpiece surface are improved, thereby improving the fatigue resistance of the workpiece, increasing the adhesion between it and the coating, extending the durability of the coating, and also facilitating the leveling and decoration of the coating.

48.Anodizing technology – sandblasting

It refers to the combination of sandblasting and anodizing. First, use purified compressed air to spray dry sand or other abrasives onto the surface of aluminum products, presenting a uniform matte sand surface. Then, anodizing is used to produce an oxide film on the surface of the workpiece, and dyeing is performed at the same time to improve the corrosion resistance and aesthetic appearance of the workpiece.