Today, Gaofeng will introduce to you some of our most common fixtures for CNC maching , hoping it can help you.

1, Chuck

The chuck is the most commonly used fixture in our CNC processing. As the saying goes, a lathe cannot be without it!

2, T-shaped workbench

Although it is not as commonly used as a chuck, if it is not there one day, your machine tool will not know how to work.

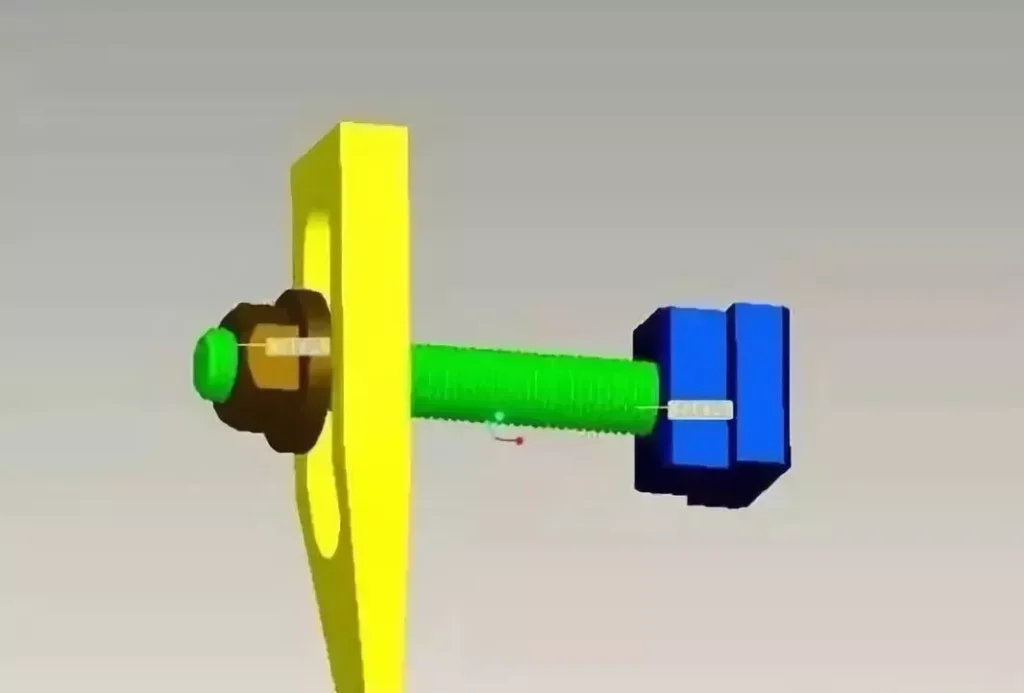

3, T-block, screw,

Combination of pressure plate and nut

No matter how awesome your fixture is, if you don’t have a T-block, the screw, platen, and nut won’t fit on the milling machine!

4, Clamp

There are many kinds of fixtures. Special fixtures can maintain ultra-high repeat positioning accuracy. CNC processing cannot be done without them, and four-axis and five-axis machining cannot be done without them.

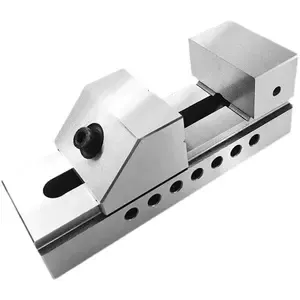

5, Vice and his brother Max

If the pressure plate cannot hold the workpiece down, you need to consider using a vise/mice to clamp it.

6, Spindle and tool holder

These two are the crystallization of human top wisdom and cutting-edge technology.

7, Magnetic table

The magnetic table can easily place unclamped parts on the workbench and allow you to process them at will!

8, Spring Collet

It can reduce the use of cutting tools, thus meeting the requirements of clamping processing!

9, Pneumatic Cylinder Clamp

The fixture that can realize automatic clamping is very popular among processing operators!

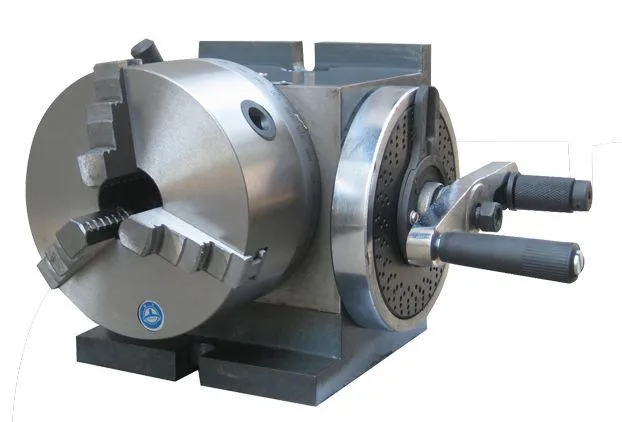

10, Dividing head

It was once very popular, but now it has fallen into decline. We have to “thank” the indexing spindle, which is the culprit!

These are the ten most commonly used fixtures in our machining industry.