CNC plastic materials

The following is a summary of common CNC plastic materials, their scientific names (or common names), Rockwell hardness (if specific values are difficult to unify, hardness descriptions are provided), and their application areas:

| Material | scientific name | hardness | application |

| ABS | Acrylonitrile – butadiene – styrene copolymer | Moderate, hard and rigid | It is widely used in the manufacturing industry and chemical field, such as parts and housings in the automotive, electronic and electrical appliances, toys, construction and other industries. |

| PC | polycarbonate | high | Household appliances, automotive lamps, medical instruments, packaging containers, etc., due to their high mechanical, optical, electrical and thermal properties. |

| PA | Polyamide (commonly known as: nylon) | High, wear-resistant, self-lubricating | It is widely used to replace copper and non-ferrous metals in the production of machinery, chemical and electrical parts, such as diesel engine fuel pump gears, water pumps, high-pressure seals, oil pipelines, etc. |

| PP | Polypropylene | Moderate, chemical resistance, heat resistance | Machinery, automobiles, electronics and electrical appliances, construction, textiles, packaging, agriculture, forestry, fisheries and food industries, etc. |

| PE | Polyethylene | Low, but impact resistant | Commonly used in the manufacture of plastic bags, containers, pipes, etc. |

| POM | Polyoxymethylene resin (commonly known as: Saigang) | High, light weight, high steel, high wear resistance | It is commonly used in gears, bearings, auto parts, machine tools, daily necessities, pipes and accessories, precision instruments and building materials. |

| PBT | polybutylene terephthalate | Higher | Mainly used in the automotive, electronic and industrial fields, to manufacture connectors, relays, switches, etc. |

| PET | Polyethylene terephthalate (commonly known as: polyester resin) | Moderate, high transparency, non-toxic and odorless | It is widely used in the textile industry, capacitors, cable insulation, electrode slot insulation, movie films, X- ray films, recording tapes, engineering plastics, auto parts, packaging materials and other fields. |

| PPS | polyphenylene sulfide | High, high temperature resistance, corrosion resistance | It is suitable for the manufacture of heat-resistant parts, insulation parts, chemical equipment, optical equipment and other parts. |

| PSU | polysulfone | High, heat and hydrolysis resistance | Commonly used in the manufacture of medical equipment, food processing equipment, precision instruments, etc. |

| PPE | polyphenylene ether | High, impact and heat resistant | Used to manufacture parts for automobiles, electronics, aerospace and other fields. |

| PVC | polyvinyl chloride | Moderate, good weather resistance | Commonly used in the manufacture of pipes, wires and cables, floors, doors and windows, etc. |

| PMMA | Organic glass (commonly known as: acrylic) | Moderate, good transparency, easy to process | Widely used in advertising, decoration, lighting, furniture and other fields. |

| PTFE | Polytetrafluoroethylene (commonly known as: Teflon) | Low, but resistant to friction and high temperature | It is often used as a non-stick coating or easy-to-clean material, and is also used to manufacture the lining of water pipes, etc. |

| PEEK | polyetheretherketone | High, high temperature resistance, self-lubricating | It can be manufactured and processed into various mechanical parts, such as automobile gears, oil screens, shift starter discs, aircraft engine parts, etc. |

| electroplated plate | – | Hardness varies depending on the plating layer | It is mainly used to manufacture parts that need to be beautiful and rust-proof, such as automobile shells, home appliance shells, etc. |

CNC metal materials

The following is a detailed introduction to common CNC metal materials, their abbreviations, various models, Rockwell hardness ( HRC ), and application areas:

| aterial | model | Rockwell hardness ( HRC ) | Application Areas |

| brass | H62 , H65 , H68 , etc. | Approximately HRB 60-80 (Brass is usually measured using the HRB scale, but an approximate range is given for comparison; the actual HRC is lower) | Electrical connectors, instruments and meters, bathroom accessories, artworks, etc. |

| Copper | T1 , T2 , T3 , etc. | It is relatively soft and is not suitable for HRC scale. It is usually expressed in HRB , about HRB 30~70 | Electricity, home appliances, construction, automotive industry, industrial gears, artworks, etc. |

| aluminum alloy | 1060 , 2024 , 6061 , 7075 , etc. | 6061 : About HRB 60~90 (before heat treatment), can be increased to HRC 40 after heat treatment ; 7075 : After heat treatment, it can reach HRC 48~60 | Aerospace components, automotive parts, electronic product casings, building structures, etc. |

| Stainless steel | 304 , 316 , 316L , 2205 , etc. | 304 : about HRB 80~100 (depending on the heat treatment process, HRC is lower); 316 and 316L : slightly higher than 304 | Kitchenware, medical equipment, chemical containers, food processing equipment, aerospace, etc. |

| titanium alloy | TA1 , TA2 , TC4 , etc. | About HRC 30~40 (depending on alloy composition and heat treatment process) | Aerospace, automobile, medical equipment manufacturing, artificial joints, sporting goods, etc. |

| mild steel | Q235 , A36 , etc. | Approximately HRB 80~120 (mild carbon steel is softer and not suitable for HRC scale, so HRB is often used to indicate it) | Mechanical parts, jigs, fixtures, tie rods, building structures, etc. |

| alloy steel | 45# , 40Cr , 20CrMnTi , etc. | 45# : After heat treatment, HRC 40~50 can be achieved ; 40Cr : After heat treatment, HRC 50~55 can be achieved | Auto parts, machinery and equipment, tools, bearings, etc. |

| tool steel | T7 , T8 , T10 , D2 , A2 , etc. | T7~T10 : After heat treatment, it can reach HRC 55~62 ; D2 , A2 : After heat treatment, it can reach HRC 60~65 | Manufacturing of cutting tools, molds, measuring tools, cutting tools, etc. |

| Zinc Alloy | ZnAl4Cu1 (expressed by composition, non-standard model) | Zinc alloy has a low hardness and is not suitable for HRC scale, and is usually represented by HB or HRB. | Auto parts, die castings, small hardware, etc. |

| Nickel alloy | Inconel 600 , Inconel 718 , Hastelloy C-276 , etc. | Depends on the specific alloy composition and heat treatment process. Generally, the hardness is higher, but the specific HRC value needs to be based on the material specification. | Manufacturing of components in high temperature, high pressure and strong corrosive environments, such as aerospace, petrochemical and other fields |

| Tungsten Alloy | – | Extremely high hardness, up to HRC 80 or above (depending on composition and process) | Manufacturing of high-density, high-hardness components, such as artillery shells, radiation shielding, etc. |

| Magnesium Alloy | AZ91D , AM60B , etc. | Magnesium alloys have a low hardness and are not suitable for the HRC scale, and are usually represented by HB or HRB. | Aerospace, automobile, electronics, communications, medical equipment and other fields |

| Monel alloy | Monel 400 , Monel K500 , etc. | Depends on the specific alloy composition and heat treatment process. Generally, the hardness is moderate, but the specific HRC value needs to be based on the material specification. | Aerospace, marine engineering, chemical industry, oil and gas and other fields |

| Inconel | Such as 304L (a type of stainless steel, but emphasizing its chromium and nickel content) | Similar to stainless steel, but different in composition and process, with similar hardness and lower HRC | Aviation, aerospace, petrochemical, nuclear power and other fields, emphasizing corrosion resistance, high temperature strength and oxidation resistance |

Hardness Description

The Rockwell hardness value ( HRC ) is affected by many factors such as alloy composition, heat treatment process, and testing method. Therefore, the above hardness range is for reference only.

Some materials (such as plastic, brass, copper, mild steel, magnesium alloy, etc.) are relatively soft and are not suitable for the HRC scale. The HRB or HB scale is often used to indicate hardness.

lFor extremely hard materials such as nickel alloy and tungsten alloy, the specific HRC value must be determined based on the material specification or actual testing.

Application field expansion

Brass is widely used in electrical and construction fields due to its good electrical conductivity and corrosion resistance.

Due to its good ductility and plasticity, copper is suitable for making parts and artworks of various shapes .

Aluminum alloys are widely used in aerospace and automotive fields due to their light weight and high strength.

lStainless steel is widely used in architectural decoration, kitchen utensils, medical equipment, etc. due to its corrosion resistance, high temperature resistance and aesthetics.

Titanium alloys are widely used in aerospace, medical and sporting goods due to their high strength, low density and good biocompatibility.

CNC special materials

The following is a summary of common special materials used in CNC machining, their hardness, and application areas:

| Material | hardness | application |

| Substitute wood (also known as imitation wood, artificial wood) | The hardness varies depending on the material formula and manufacturing process, and is generally softer | It is often used in model making, prototype making, inspection tool making and other fields, and is popular due to its good processing performance and low cost. |

| Bakelite (phenolic plastic) | High hardness, wear resistance, heat resistance and corrosion resistance | Commonly used in electrical switches, sockets, insulation boards and other fields, due to its good insulation performance and heat resistance. |

| graphite | Hardness varies depending on purity and crystal form, industrial graphite is generally softer | It is commonly used in electrode manufacturing, casting molds, pencil leads and other fields, and is popular for its good conductivity, high temperature resistance and lubricity. |

| Synthetic stone (also known as artificial stone) | High hardness, wear resistance, corrosion resistance and high temperature resistance | Commonly used in wear-resistant parts, corrosion-resistant parts, high-temperature parts and other fields, such as mechanical seal rings, pump bodies, valves, etc. |

| Carbon Fiber | Extremely high hardness, high specific strength and specific modulus | It is commonly used in aerospace, sports equipment, automobile manufacturing and other fields, and is favored for its excellent properties such as light weight, high strength, corrosion resistance and high temperature resistance. |

| Fiberglass | High hardness, good strength and toughness | It is commonly used in composite material manufacturing, shipbuilding, piping systems and other fields, and is widely used due to its light weight, high strength, corrosion resistance, and wear resistance. |

Regarding the hardness of the above materials, it is important to note that hardness values are affected by a variety of factors, including material formulation, manufacturing process, purity, and crystal morphology. Therefore, it is impossible to provide accurate hardness values for all materials. In actual applications, you can refer to the data provided by the material supplier or conduct actual testing to determine the specific hardness.

The application areas of the above materials only list some common uses. In fact, their application range is very wide and can be selected and applied according to specific needs. In CNC machining, selecting the right materials and machining parameters is of great significance to ensuring machining quality and reducing production costs.

The above information is for reference only. If you need more detailed data, it is recommended to consult the relevant material manual or consult the material supplier.

How to choose the right material for CNC machining

A huge number of machining orders are available on Duigou.com! Follow ” Duigou.com Machining Orders ” to receive real-time machining order push notifications, making it easier to place orders!

If the materials are wrong, everything will be in vain!

There are many materials suitable for CNC machining. Choosing the right material for your product is subject to many factors, but a fundamental principle is that the material’s performance must meet the product’s technical and environmental requirements. When selecting materials for mechanical parts , consider the following five aspects.

Is the material rigid enough?

Rigidity is the primary consideration when selecting materials, because the product requires a certain degree of stability and wear resistance in actual work, and the rigidity of the material determines the feasibility of the product design.

According to the characteristics of the industry, 45 steel and aluminum alloy are usually chosen for non-standard tooling design; 45 steel and alloy steel are used more frequently for tooling design in machining; and aluminum alloy is mostly chosen for tooling design in the automation industry.

How stable is the material?

For a product with high precision requirements, if it is not stable enough, various deformations will occur after assembly, or it will deform again during use. In short, it will continue to deform with changes in the environment such as temperature, humidity and vibration. This is a nightmare for the product.

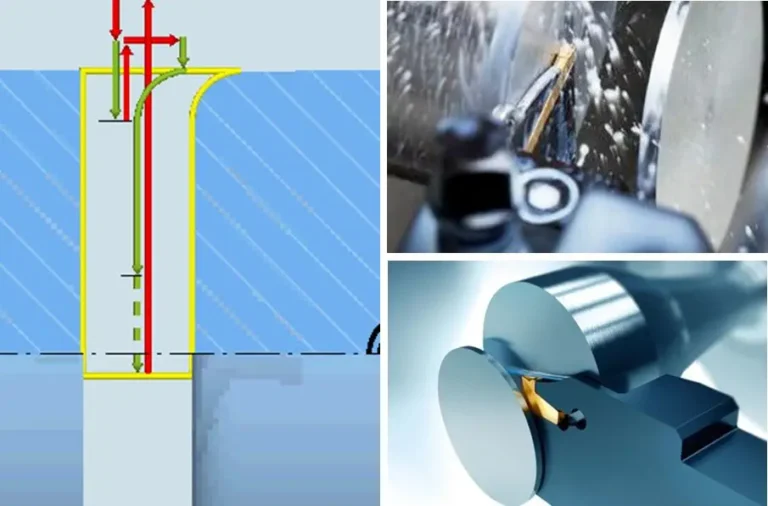

What is the material processing performance?

The material’s machinability determines the ease with which a part can be machined. While stainless steel is rust-resistant , it’s difficult to machine due to its high hardness, which can easily wear out cutting tools during machining. Machining small holes, especially threaded holes, in stainless steel can easily break drill bits and taps, leading to very high machining costs.

Anti-rust treatment of materials

Rust prevention is crucial to the stability and appearance of a product. For example, 45 steel is typically treated with a blackening treatment, or the parts are sprayed with paint or plastic. Depending on the environment, sealing oil or anti-rust liquid may also be used during use.

There are many anti-rust treatment processes, but if the above methods are not suitable, then you must change the material, such as stainless steel. In any case, the rust prevention of the product cannot be ignored.

What is the material cost?

Cost is a key consideration in material selection. Titanium alloys, with their light weight, high specific strength, and excellent corrosion resistance, are widely used in automotive engine systems, playing an invaluable role in energy conservation and consumption reduction.

Although titanium alloy parts have such superior performance, the main reason hindering the widespread use of titanium alloys in the automotive industry is still the high cost. If it is not really necessary, choose a cheaper material.