Introduction

Among the many molding processes used for plastic products, injection molding is the most common and widely used. This process can be further subdivided into various types. Generally speaking, conventional injection molding can achieve basic appearance effects such as texture, highlights, and styling, so I won’t go into detail here. This article will focus on the following seven process options , covering multi-color and multi-material effects, precision injection molding, material mixing, and structural molding (thin-wall, porous, etc.).

Two-shot and multi-shot implantation technology

Secondary injection molding (beer encapsulation process)

Insert molding

Nano injection molding

Foam injection molding

Spray-free injection molding

Injection compression molding

These are the commonly used process solutions for CMF design in different product areas. I believe that after reading this article, you will have a clearer understanding of the injection molding process in the entire CMF industry! This article only introduces the processes commonly used in product CMF design and does not include some non-CMF or less relevant technologies.

1.Two-shot and multi-shot implantation technology

Two-shot injection molding, also known as dual-material molding, is a well-established process. It’s a solution for achieving a two-color finish on plastic surfaces. Using two materials to create a single product, it can achieve distinct colors and textures. This improves efficiency, reduces costs, and allows for greater design freedom, making it a widely used technology.

However, with the continuous advancement of product design and process technology, simply two colors are no longer sufficient. How can a soft touch, multiple color effects, logos, electronic components, and aesthetically pleasing designs be combined? Traditional injection molding assembly is too cumbersome, leading to the emergence of three-color and multi-color integrated molding technology. This is crucial for CMF designers and product developers to understand.

This is an injection molding process for a variety of materials, allowing for a variety of combinations, such as plastic + plastic, plastic + silicone, and plastic + fabric. This not only allows for a variety of color combinations but also allows for multifunctional integration by embedding appropriate hardware, electronic chips, and other internal components, significantly reducing assembly steps and saving product production costs. This truly achieves miniaturization, intelligence, multi-functions, and personalization, offering unique advantages in the field of precision injection molding products with small functional areas.

2.Secondary injection molding (beer encapsulation process)

Secondary injection molding differs from two-shot molding, commonly known in the industry as “overmolding” or “encapsulation.” Secondary injection molding involves remolding a previously molded plastic product. The number of injections can be determined based on design requirements. Generally speaking, the first injection is called the base material, while the subsequent injections are called the cover material.

Throughout the entire process, the covering material can be combined above, below, left, right, or even inside the substrate, typically through multiple injection molding or insert molding. This technology has been developed for approximately 20 years and is widely used to create “soft-touch surfaces,” particularly in the medical industry. Overmolding not only enhances a product’s appearance but also expands its functional qualities, such as shockproofing and waterproofing. Currently, overmolding is widely used in the medical, home appliance, consumer electronics, and toy industries.

3. Insert molding

Insert molding involves inserting a pre-prepared insert of another material (such as metal) into a mold before proceeding with the injection molding process. The plastic and insert bond and solidify in the mold, creating an integrated product. For example, MAGPLAYER magnetic building blocks have magnets embedded in them during the injection molding process.

The general process for insert molding includes: insert placement → vacuum fixation → injection molding. This process is widely used in home appliances, consumer electronics, toys, and other fields. Its advantages include a perfect combination of plasticity and rigidity tailored to design requirements, high reliability of the insert-to-main component composite, and automated mass production capabilities.

It is worth mentioning that in-mold injection molding is similar to insert injection molding. The author wrote a very detailed article earlier. If you want to know more in depth, you can click to watch: 40 pictures of comprehensive and professional analysis: IML|IMT|IMR|INS|IME and other in-mold injection molding processes.

4. Nano injection molding

Nanomolding (NMT) technology gained popularity around 2015, coinciding with the early days of all-metal smartphones. It utilizes a microscopic dual-material solution combining plastic and metal. After the metal surface undergoes a nano-processing process, plastic is directly injection-molded onto it, creating a single, integrated form. The advantages are clear, primarily avoiding signal shielding associated with full metal construction. While maintaining functionality, it also creates a seamless, smooth surface that creates the illusion of a single, integrated unit.

Nanomolding technology is divided into two categories according to the location of the plastic:

The plastic is integrally molded for non-exterior surfaces;

The plastic is integrally molded for the exterior surface.

Nano injection molding process features:

The product has a metallic appearance and texture;

The simplified design of product components makes the product lighter, thinner, shorter and smaller, and more cost-effective than CNC machining methods;

Reduce production costs and increase bonding strength, and significantly reduce the usage of related consumables.

5. Foam injection molding

The foaming process refers to adding a foaming agent to the material to form a porous honeycomb structure through physical or chemical reactions.

The foaming process mainly includes three stages: bubble nucleus formation, bubble growth, and bubble stabilization. The gas is dissolved in the liquid polymer to produce gas to saturate the solution, followed by nucleation to form bubble nuclei. After the bubble nuclei are stabilized, they expand to form a foam body, and finally the structure of the foam body is fixed.

Microfoam injection molding is a precision injection molding technique that primarily relies on the expansion of pores to fill the product. The general principle is that a supercritical fluid (nitrogen or carbon dioxide) acts as a physical foaming agent, creating microfoam within the molded part. This creates a large number of bubble nuclei, which gradually grow to form tiny pores. These pores then expand and fill the part. Molding is performed under low, even pressure. Microbubbles typically range in size from 1μm to 100μm. This technology enables the production of parts with dimensional accuracy between 0.01 and 0.001mm, sometimes even below 0.001mm. Compared to traditional injection molding processes, parts produced using microfoam injection molding exhibit superior mechanical properties and dimensional stability, as well as high dimensional accuracy and repeatability, and tight tolerances.

6. Spray-free injection molding

The spray-free process, first introduced in 2016, eliminates the need for post-processing such as painting. Instead, the process is created by injection molding plastic pellets with special metallic colors in a single step. The resulting product, with its own inherent color and texture, can achieve a variety of aesthetic effects, including metal, ceramic, and even fabric imitations. Manufacturers have long since resolved issues like weld marks and flow marks, and the process has been adopted for mass production in industries such as home appliances and cosmetics.

To achieve high-gloss, trace-free spraying, there are very high requirements in material selection and mold design. For example, the material’s fluidity, stability, glossiness and some mechanical properties must be considered; the mold may need to consider temperature resistance, water channels, and the strength of the mold material itself.

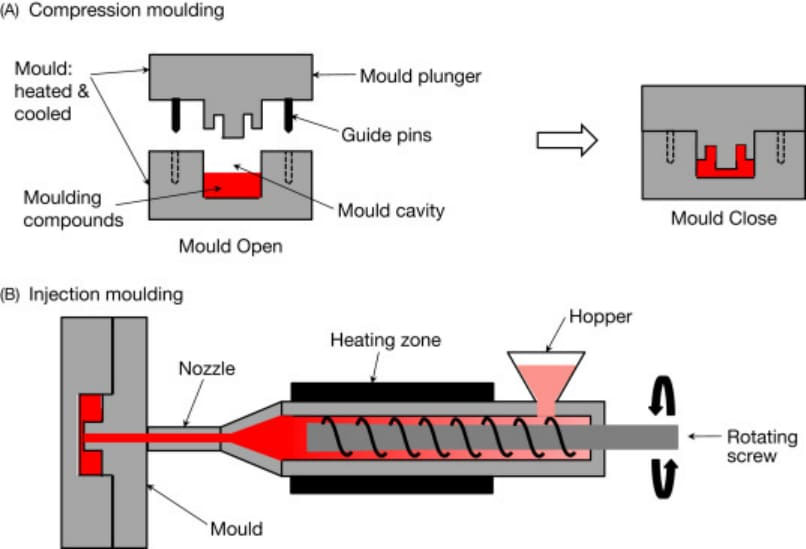

7. Injection compression molding

The first time I learned about this injection molding technology was in 2018. At that time, the popular mobile phone back cover imitation glass technology was made using the transparent PC injection compression molding process.

This is a thin-wall injection molding technology solution that combines injection molding and compression processes. It has stable dimensions and precise surfaces. It is an advanced form of injection molding and can create very thin products.

| Advantages | Disadvantages |

|---|---|

| Requires lower injection pressure, reducing appearance defects | Injection process is more complex compared to traditional injection molding |

| Lower product internal stress due to minimal shear stress in the melt | Higher equipment cost under the same mold clamping force |

| More uniform packing pressure, improving surface quality and reducing rainbow patterns | Injection-compression molds are more complex, requiring specialized molds with higher technical demands |

| Increased product density and reduced internal stress, enhancing chemical resistance | Requires purchasing specialized injection equipment |

| Enables use of higher-grade hardening fluid to achieve higher product hardness | Only suitable for relatively flat parts, not for complex geometries |

| Requires smaller clamping force, enabling multi-cavity production on smaller machines for higher efficiency | |

| Reduces risk of internal stress deformation and tiger stripe defects; requires fewer ejector pins, minimizing weld line risks, ensuring dimensional stability and appearance | Can be adapted from standard machines, reducing equipment investment |

The process flow is roughly as follows: acquisition of PC raw materials → compression injection molding (including mold texturing and other processing) → CNC processing and finishing → plastic hardening (generally curtain coating) → polishing, fine carving and finishing and other post-processing → cleaning and packaging, etc.

There are other processes similar to low-pressure injection molding (mainly for internal electronic components such as sensors, connectors, antennas, etc.), which are not very relevant to CMF, so I will not introduce them in detail!