Introduction

Selective Laser Sintering (SLS), as one of the 3D printing processes , was first proposed by C.R. Dechard of the University of Texas at Austin in his master’s thesis in 1989. C.R. Dechard then founded DTM and released the Sinterstation, an industrial-grade commercial 3D printer based on SLS technology, in 1992.

For over two decades, the University of Texas at Austin and DTM have invested heavily in SLS research, achieving fruitful results in equipment development, process, and material development. Germany’s EOS has also conducted extensive research on SLS and developed a series of industrial-grade SLS rapid prototyping equipment. EOS’s 3D printing equipment was a major highlight at the 2012 European Mold Show.

The development history of SLS technology

In 1986, Deckard, a graduate student at the University of Texas, proposed the concept of Selective Laser Sintering (SLS) and obtained the first SLS technology patent in 1989 [3]. This is a rapid prototyping (RP) technology that uses infrared laser as a heat source to sinter powder materials. Like other rapid prototyping technologies, SLS technology uses the principle of discrete/accumulated forming and, with the help of computer-aided design and manufacturing, directly forms solid powder materials into three-dimensional solid parts. It is not limited by the complexity of the shape of the formed parts and does not require any tooling or molds.

In 1992, DTM, a US company, launched the Sinterstation 2000 series of commercial SLS molding machines. The improved Sinterstation 2500 and Sinterstation 2500 plus followed in 1996 and 1998 , respectively. The company also developed a variety of sintering materials, enabling the direct manufacture of wax models as well as plastic, ceramic, and metal parts. Due to its broad application prospects in new product development, mold manufacturing, and small-batch production, SLS technology has rapidly developed over the past decade and has become one of the most mature and widely used rapid prototyping technologies.

Another major player in SLS technology is Germany’s EOS. Founded in 1989, EOS launched three series of SLS machines in 1994: the EOSINT P for sintering thermoplastic powders to create functional plastic parts and prototypes for investment and vacuum casting; the EOSINT M for directly sintering metal powders to create metal molds and parts; and the EOSINT S for directly sintering resin-bonded sand to create complex sand molds and cores. EOS has continuously improved and upgraded the hardware and software of these machines, resulting in faster build speeds, higher precision, easier operation, and the ability to produce larger sintered parts. EOS has experienced strong growth in recent years, and its products have secured a significant market share in the US.

SLS process principle

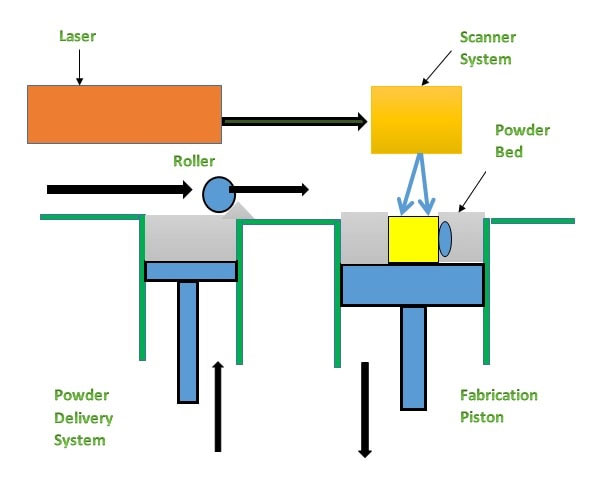

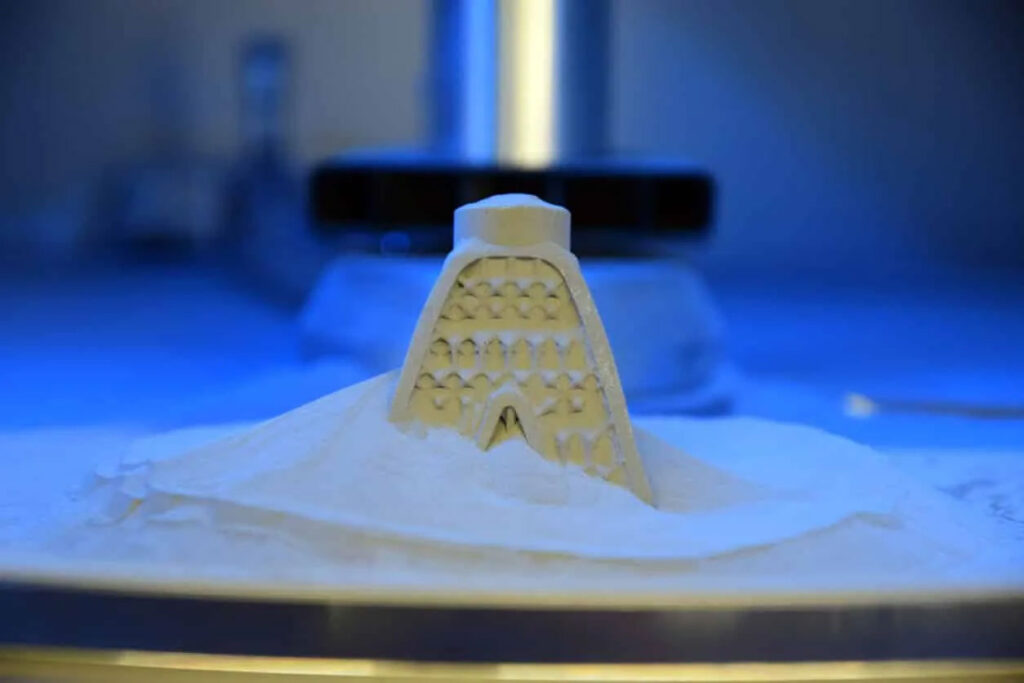

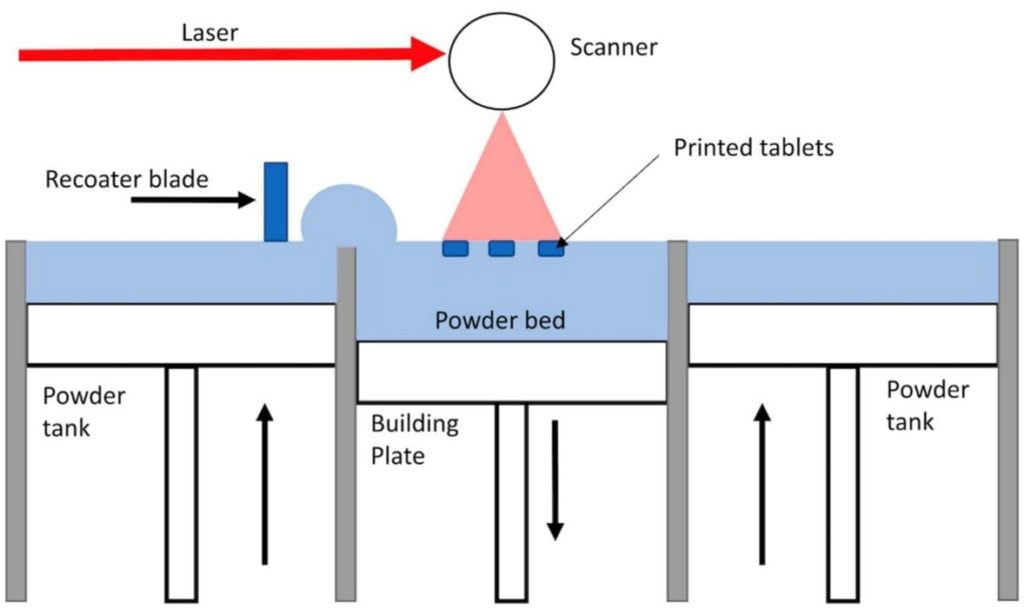

The SLS process uses powdered materials. The laser scans and irradiates the powder under computer control to achieve sintering and bonding of the materials. In this way, the materials are stacked layer by layer to achieve molding. The figure shows the molding principle of SLS:

The selective laser sintering process first uses a pressure roller to spread a layer of powder onto the upper surface of the formed workpiece. The CNC system controls the laser beam to scan and irradiate the powder layer according to the cross-sectional contour of the layer, raising the temperature of the powder to the melting point, thereby sintering it and bonding it to the formed part below.

When one layer of cross section is sintered, the workbench will drop one layer thickness. At this time, the pressing roller will evenly spread a layer of powder on it and start sintering a new layer of cross section. This operation is repeated until the workpiece is completely formed.

During the molding process, the unsintered powder supports the model’s cavities and cantilevers, so SLS molded parts do not require support structures like SLA molded parts. The materials used in the SLS process are relatively richer than those used in SLA, mainly including paraffin wax, polycarbonate, nylon, fine nylon, synthetic nylon, ceramics, and even metals.

When the workpiece is fully formed and completely cooled, the workbench will rise to its original height. At this time, the workpiece needs to be taken out and the powder on the surface of the model needs to be removed using a brush or compressed air.

The SLS process supports a wide range of materials, eliminates the need for support structures, and offers high material utilization. Despite this, the cost of SLS equipment and materials remains high. The materials must be preheated before sintering, and the sintering process produces odors, leading to relatively demanding operating environments.

SLS process characteristics

A variety of materials can be used: Theoretically, this method can use any powder material whose viscosity decreases when heated, from polymer material powder to metal powder, ceramic powder, and quartz sand powder can be used as sintering materials.

Simple manufacturing process: Since the unsintered powder can support the cavity and cantilever parts of the model, there is no need to design a separate support structure as in Stereo Lithography Apparatus (SLA) and Fused Deposition Molding (FDM) processes, and complex prototypes and components can be directly produced.

High material utilization rate: Unsintered powder can be reused, no material waste and low cost.

Forming accuracy :The forming accuracy depends on the type of material used, particle size, product geometry and complexity, etc. The prototype accuracy can reach ±1%.

Wide range of applications: Due to the diversity of forming materials, different forming materials can be selected to produce sintered parts for different purposes, such as plastic functional parts for structure verification and functional testing, metal parts and molds, wax molds and sand molds for precision casting, sand cores, etc.

SLS process raw materials

Sintering materials are a key factor in the development of SLS technology. They play a decisive role in the forming speed, precision, and physical and mechanical properties of sintered parts, directly affecting their application and the competitiveness of SLS technology compared to other rapid prototyping technologies. Currently, a variety of laser sintering materials have been developed, which can be divided into the following categories based on their properties: metal-based powder materials, ceramic-based powder materials, coated sand, and polymer-based powder materials.

Metal-based powder materials

Metal-based powder materials fall into two main categories. One type is metal powder using a polymer as a binder. This includes coated metal powders (such as DTM’s RapidSteel 2.0) made by coating metal powder materials with organic polymers, and mixed powders of metal and organic polymers. During the laser sintering process, the metal particles of this type of metal powder are bonded together by the organic polymer to form a green part. This green part undergoes post-processing, such as high-temperature removal of the organic polymer and copper infiltration, to produce dense metal parts and molds. The other type is metal powder without an organic binder. This type of metal powder can be directly sintered using high-power lasers into high-density functional metal parts and molds.

Ceramic materials

Ceramic materials have very high sintering temperatures, making them difficult to form directly using laser sintering. Therefore, the ceramic-based powder material used in the SLs process is a ceramic powder with a binder. During the laser sintering process, the ceramic powder is bonded together using a melted binder to form a specific shape, which is then post-processed to achieve sufficient strength. Commonly used binders include the following three types:

① Organic binders, such as polymethyl methacrylate (PMMA), are used to coat ceramic powder materials such as Al2O3, ZrO2, and SiC. After laser sintering, they are then subjected to post-processing such as degreasing and high-temperature sintering to quickly manufacture ceramic shells and engineering ceramic parts for precision casting.

② Inorganic binders, such as ammonium dihydrogen phosphate (NH4HZPO4), melt and decompose during sintering to produce P2O5. P2O5 then reacts with the ceramic matrix Al2O3 to form AlPO4. AlPO4 is an inorganic binder that can bind ceramic powders together.

③ Metal binder, such as aluminum powder. The aluminum powder melts during the sintering process. The molten aluminum can bond the Al2O3 powder together. At the same time, a part of the aluminum will oxidize during the laser sintering process to generate Al2O3 and release a large amount of heat, which promotes the melting and bonding of Al2O3.

Coated sand

Coated sand, similar to hot sand used in foundries, is produced by coating zircon sand or quartz sand with a thermosetting resin such as phenolic resin. DTM’s SandForm Zr is an example. During the laser sintering process, the phenolic resin softens and solidifies upon heating, bonding the coated sand and forming the part. Due to the short laser heating time, the phenolic resin cannot fully cure in a short period of time, resulting in a low strength sintered part. Heat treatment is required before the sintered part can be used as a sand mold or core for metal castings.

polymer materials

Compared with metal and ceramic materials, polymer materials have lower forming temperatures, require less laser power for sintering, have lower surface energy, higher melt viscosity, and do not have the “spheroidization” effect that is difficult to overcome when sintering metal powders. Therefore, polymer powder is currently the most widely used and most successful SLS material. The main polymer materials are as follows:

wax powder

Traditional investment casting waxes (such as paraffin waxes and fatty acid waxes) have low mold strength, making them difficult to produce fine, complex structure castings. Furthermore, they suffer from poor molding accuracy. Therefore, DTM has developed a composite material made from low-melting-point polymer waxes.

Polystyrene (PS)

Polystyrene melts and bonds when heated, solidifying into a polystyrene upon cooling. Furthermore, this material has low moisture absorption and shrinkage. Resin-impregnated molded parts can further enhance their strength, achieving performance indicators such as tensile strength ≥15MPa, flexural strength ≥33MPa, and impact strength >3MPa. Polystyrene can be used as prototypes or functional parts, as well as as master molds for lost foam casting (LVFC) to produce metal castings. However, its disadvantage is that high-temperature combustion (>300°C) is required for demolding, which can cause environmental pollution. Therefore, decomposition aids are often added to PS powder raw materials to meet the requirements of LVFC casting. This is exemplified by DTM’s commercial product, TrueForm Polymer. While its molded parts can be manufactured using LVFC, the price is high.

Engineering plastics (ABS)

ABS and polystyrene are both thermoplastic materials. Their sintering molding properties are similar to those of polystyrene, except that the sintering temperature is about 20°C higher. However, ABS molded parts have higher strength, so they are widely used in rapid manufacturing of prototypes and functional parts at home and abroad.

Polycarbonate (PC)

Research on polycarbonate sintering is relatively mature. Its molded parts have high strength, excellent surface quality, and easy demolding. It is primarily used in the manufacture of lost foam for investment casting of metal parts in the aviation, medical, and automotive industries, as well as in the production of general-purpose plastic molds across various industries. For example, DTM’s DTM Polycarbanate. However, polycarbonate is more expensive than polystyrene. Beihang University in China is conducting research on polycarbonate (PC), exploring its sintering process to improve molded part precision.

Nylon (PA)

Nylon materials can be made into functional parts using the SLS method. Currently, there are four types of materials widely used commercially.

1) Standard DTM nylon can be used to make models with good heat resistance and corrosion resistance;

2) DuraForm GF, which not only has the same performance as DTM nylon, but also improves the dimensional accuracy of parts, reduces surface roughness, and can produce small features. It is suitable for concept and test manufacturing, but the price is high.

3) DTM Fine Nylon Medical Grade, which can be steam sterilized for 5 cycles through high-temperature autoclaving;

4) ProtoForm™ Composite is a glass-reinforced modification of DuraForm GF that offers improved processing properties and enhanced heat and corrosion resistance compared to unreinforced DTM nylon.

At the same time, EOS has developed a new nylon powder material (PA3200GF, somewhat similar to DTM’s DuraForm GF) that can produce high precision and good surface finish.

SLS Application Examples

SLS technology has been successfully applied to many industries such as automobile, shipbuilding, aerospace, aviation, communications, micro-electromechanical systems, construction, medical treatment, archaeology, etc., injecting new creativity into many traditional manufacturing industries and bringing a touch of informatization. In general, SLS technology can be applied to the following occasions:

1) Rapid prototyping: The SLS process can quickly produce prototypes of designed parts, allowing for timely evaluation and correction of products to improve design quality. It allows customers to obtain intuitive part models and can produce complex models for teaching and testing.

2) Preparation and development of new materials:The SLS process can be used to develop some new particles to reinforce composite materials and cemented carbides.

3) Manufacturing of small batches and special parts:In the manufacturing industry, the production of small batches and special parts is common. These parts have long processing cycles and high costs, and some complex parts are even impossible to manufacture. SLS technology can economically achieve the production of small batches and complex parts.

4) Rapid mold and tool manufacturing: Parts manufactured by SLS can be used directly as molds, such as investment casting, sand casting, injection molding, high-precision metal models with complex shapes, etc.; the molded parts can also be used as functional parts after post-processing.

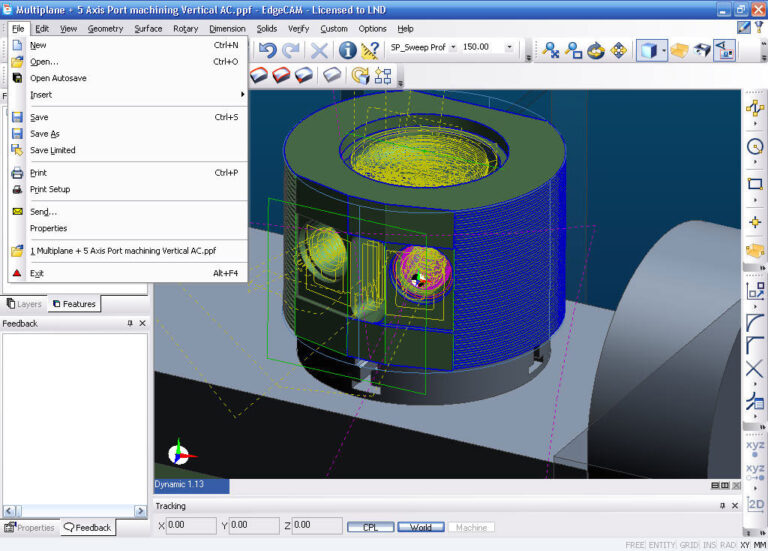

5) Application in reverse engineering: SLS technology can be used to recreate the prototype CAD model according to the existing part prototype using various digital technologies and CAD technologies when there is no design drawing or incomplete drawing and no CAD model.

6) Medical Applications: Parts sintered using the SLS process have high porosity and can therefore be used in the manufacture of artificial bones. Clinical studies conducted abroad on artificial bones produced using SLS technology have shown good biocompatibility.