A Brief Guide To Ultrasonic Machining

What is Ultrasonic Machining? Have you heard of ultrasonic machining? Also known as ultrasonic vibration machining, it is a manufacturing process that removes workpiece material…

What is Ultrasonic Machining? Have you heard of ultrasonic machining? Also known as ultrasonic vibration machining, it is a manufacturing process that removes workpiece material…

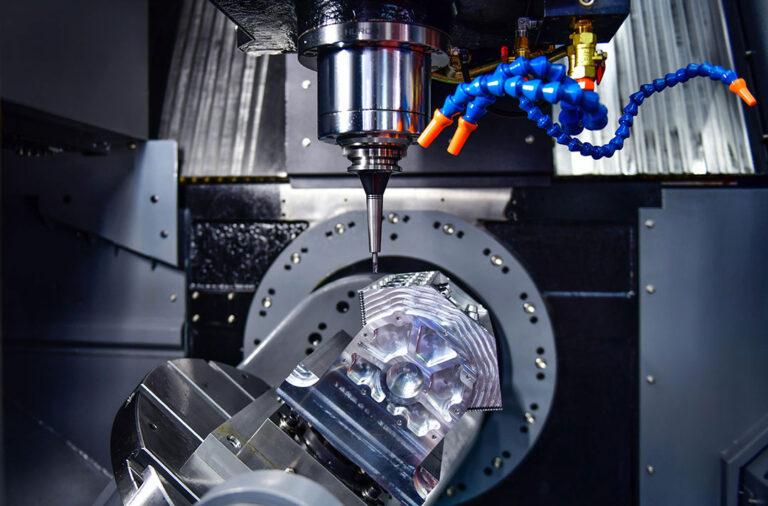

Intro CNC milling machines and CNC lathes are the two most commonly used CNC machine tools. When machining, the processes of milling and turning look…

Material properties Silicone mold Material: Mainly liquid silicone rubber (thermosetting), containing cross-linking agent and filler, with soft texture and high elasticity.Features: Wide temperature resistance range…

The pacifier is an auxiliary silicone product for feeding newborn babies. Many mothers pay great attention to the choice of pacifiers for the health of…

Introduction This is a step-by-step tutorial on how to make a silicone mold, covering the key points of how to use mold silicone to make…

Introduction Before each new product is put on the market, a market benefit analysis will be conducted on the product, or it will be necessary…

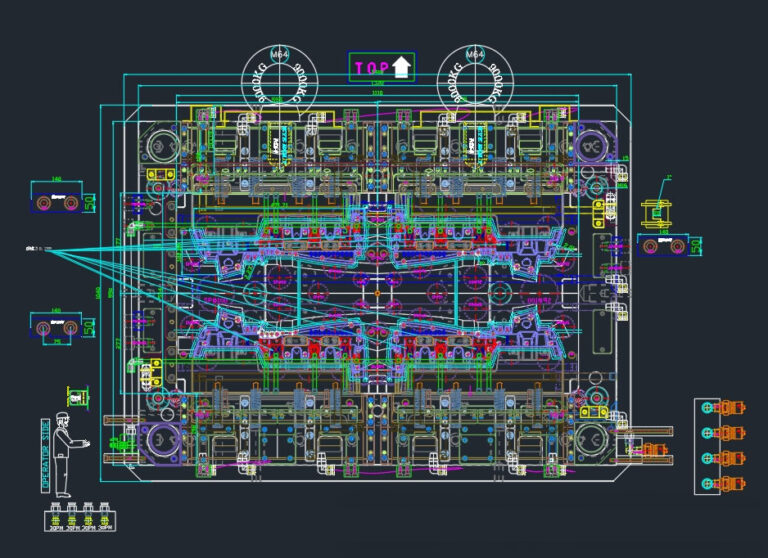

Introduction In the field of mold design, choosing a suitable software is crucial. It not only improves work efficiency, but also directly affects design quality…

Introduction In recent years, as the market’s requirements for the precision of sheet metal parts have increased, precision sheet metal processing has also begun to…

The role of liquid silicone cold runner Liquid silicone molds use cold runners, which use less material, can save production cycles, and reduce material loss….

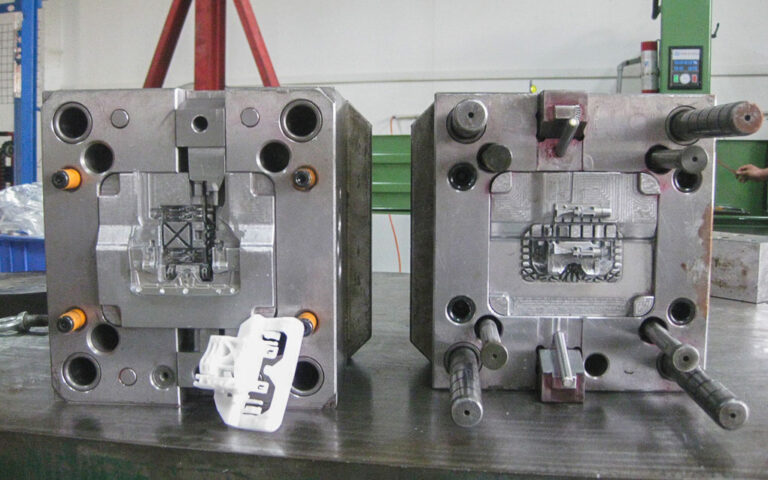

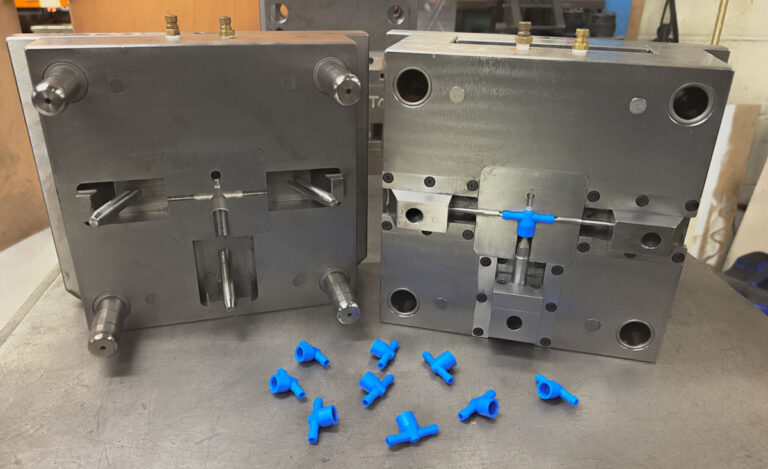

Introduction In the plastic products industry, low volume manufacturing with an annual output of less than 10,000 pieces are more and more common. Such orders…

Introduction The rise of the Industrial Revolution in the 18th century marked a new era of collaborative work between humans and machines in the manufacturing…

When aluminum alloy workpieces are machined, there are many processes to choose from. For example, laser or CNC processing is used for baffle opening. However,…

Introduction The service life of the mold (i.e. the number of times the mold can stably produce qualified products) is a core indicator that customers…

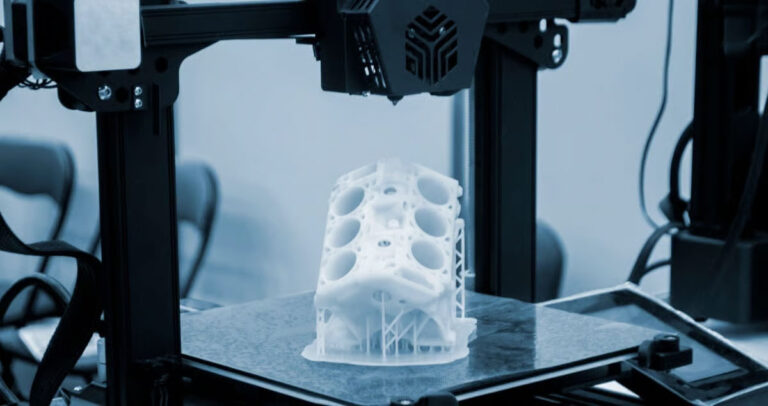

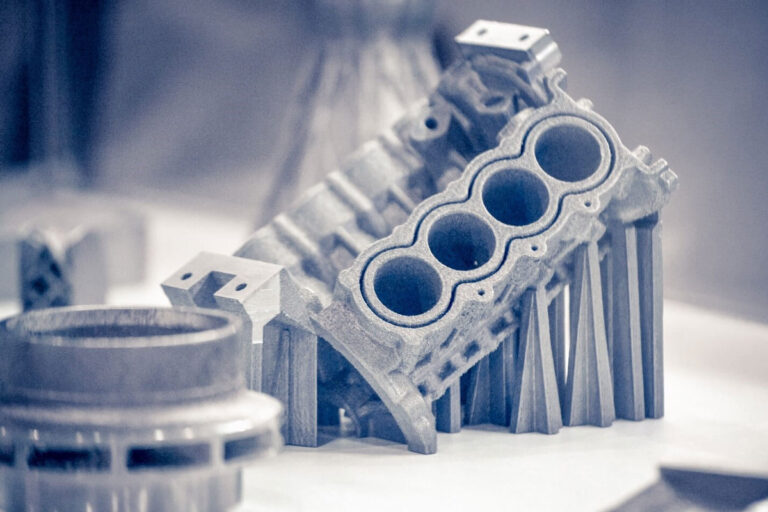

Introduction Many laymen think that 3D printing is just squeezing materials out of a hot nozzle and stacking them into shapes, but in fact, 3D…

Classification of spraying The widely used spraying processes are roughly divided into two categories: one is powder spraying, also known as powder coating, which uses…