4 Reasons For Prototype Making

With the development of technology, our technical personnel have invented a variety of products for us to use. In order to adapt to the development…

With the development of technology, our technical personnel have invented a variety of products for us to use. In order to adapt to the development…

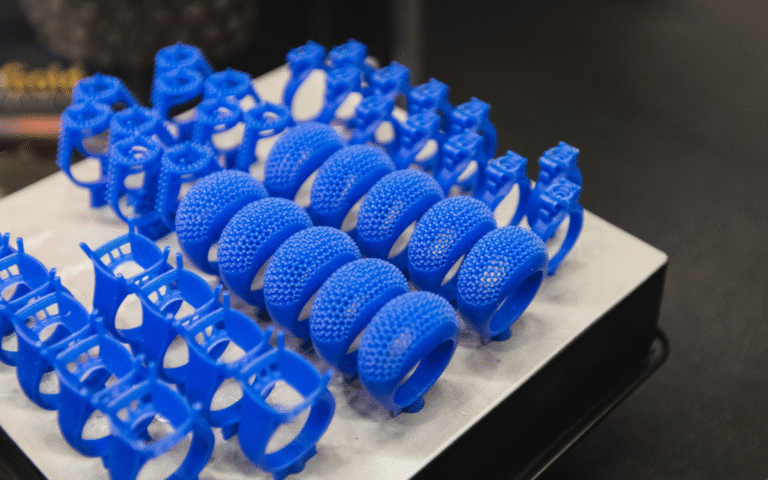

Brief Intro FDM 3D printing is one of the most widely used 3D printing technologies, and basically all FDM 3D printers use PLA and ABS…

Galvanized Features Zinc is relatively stable in dry air and is not easy to change color. In water and humid atmosphere, it reacts with oxygen…

Hello everyone! Today we’ll discuss two common surface treatment techniques used in industry—sandblasting and shot peening. While their names may sound similar, their functions and…

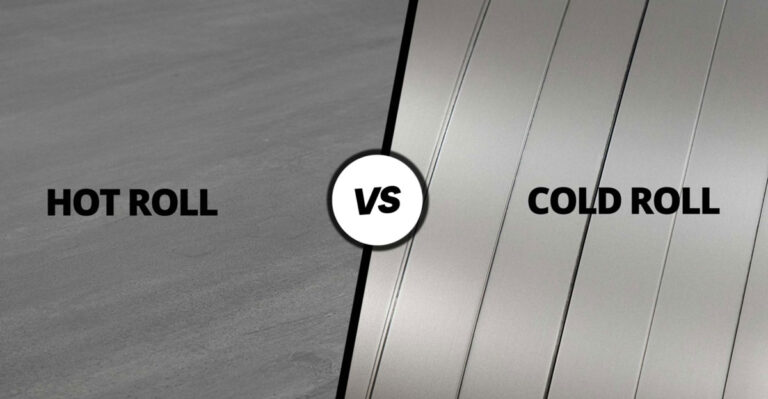

1. Different colors The surface of cold-rolled sheet is oily and silvery white, almost the same as stainless steel. The surface of the hot-rolled plate…

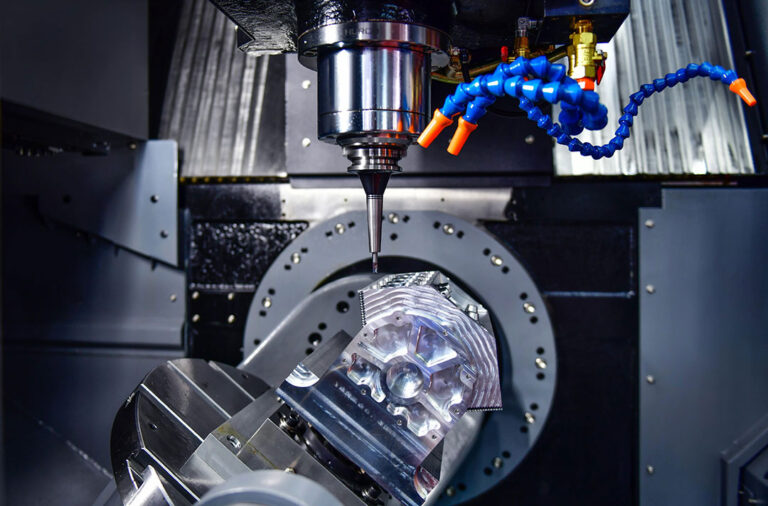

Introduction Each tool uses different processing parameters based on the material being processed. In the field of milling, tool manufacturers aim to improve processing efficiency…

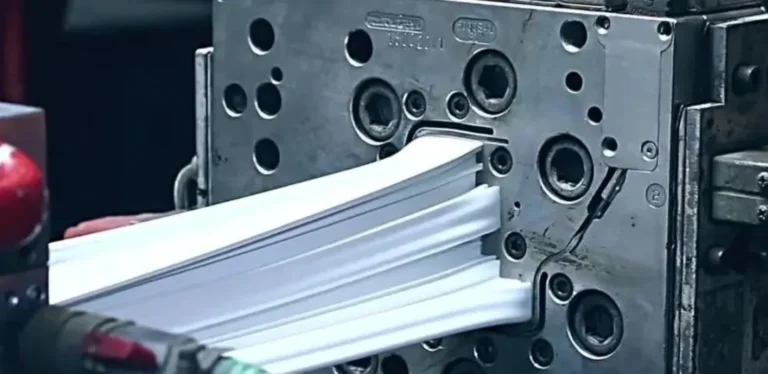

The basic principle of fusible core injection molding is to first use a low-melting-point alloy to cast a fusible core, then place the fusible core…

Production workshop The layout of the production workshop focuses on two aspects: meeting production demand conditions, optimizing the layout according to the production process, and…

Wrong speed = tool wear. Wrong feed rate = noise, burns, scrap. Recommended feed per tooth Tool diameter Aluminum alloy (mm/tooth) Steel (mm/tooth) Stainless steel…

Intro We can see a variety of materials in our daily lives. Some are familiar, while others are so closely related to our lives that…

The difference between “ABS material” and “PP material” is: 1. Different molding temperature; 2. Different performance and use Specific differences: 1.Different molding temperatures ABS material…

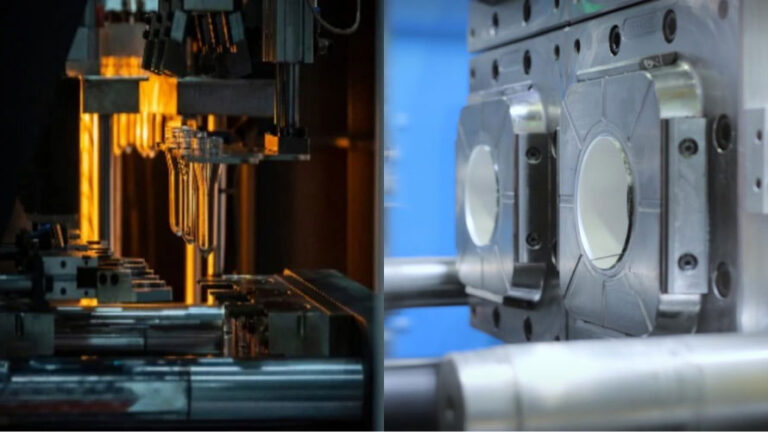

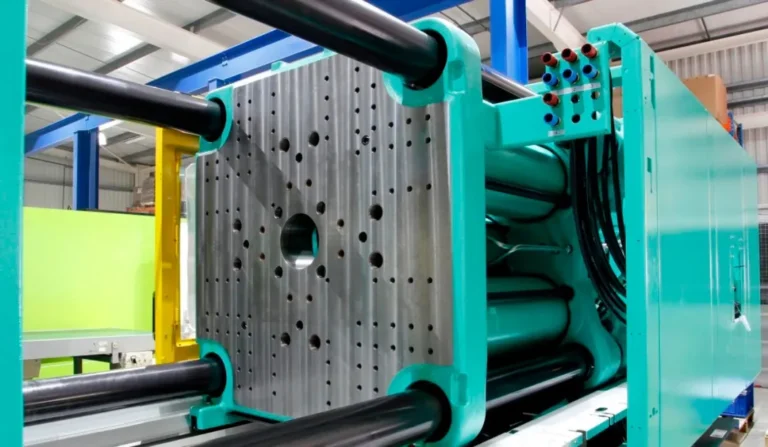

Introduction Injection molds and blow molds are two common types of plastic molds. Although the difference between the two is only one letter, there are…

Introduction The molding process of plastic products not only allows us to obtain the desired plastic products but also improves the plastic’s performance. However, the…

Intro The two mold production processes introduced today produce products that are everywhere in our lives, namely injection molding and blow molding. They have their…

Introduction Among the many molding processes used for plastic products, injection molding is the most common and widely used. This process can be further subdivided…