TPE Injection Molding: 5 Typical Surface Defects and How to Avoid Them

If the surface quality of TPE injection molded parts is critical, they must be dried before molding. This is typically done in a hopper at…

If the surface quality of TPE injection molded parts is critical, they must be dried before molding. This is typically done in a hopper at…

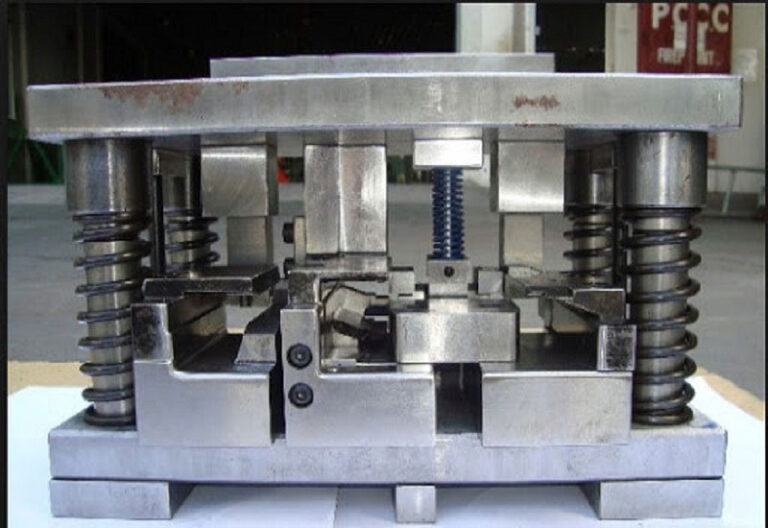

Punching burrs grow the fastest during stamping , so burr height can be considered to determine the mold maintenance and service cycle. Accordingly, when the…

The service life of the silicone mold during mold remodeling directly affects our costs. Although it is important to choose high-quality mold silicone raw materials…

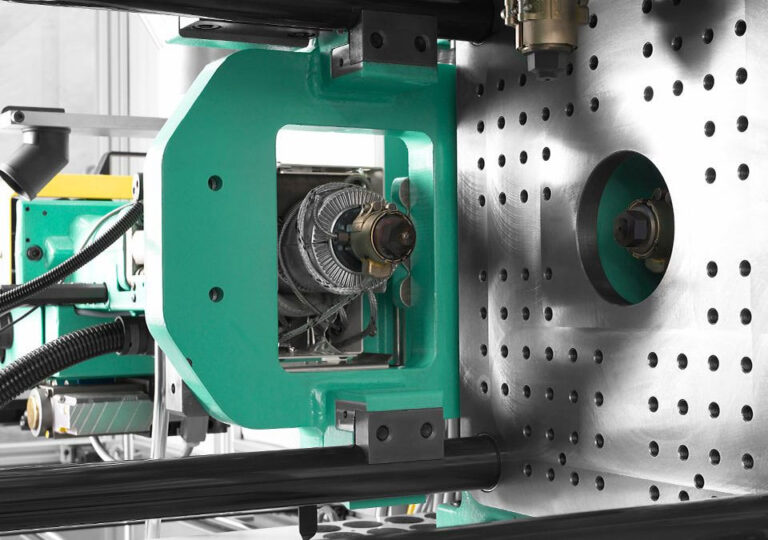

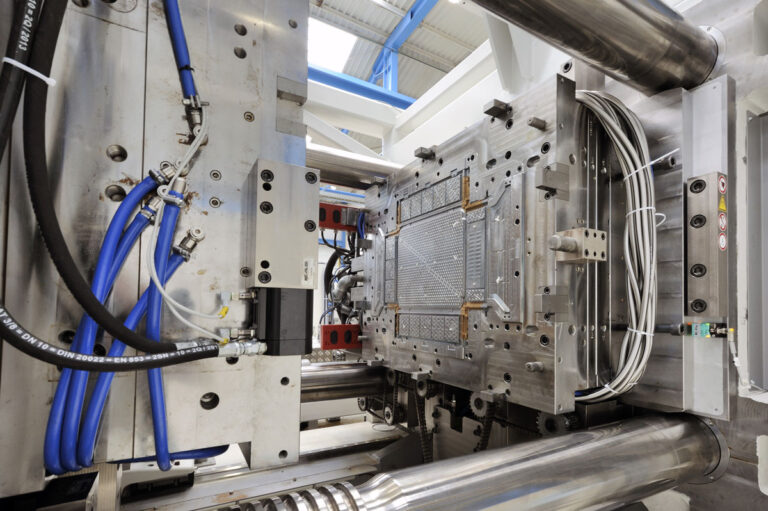

Introduction I have read many articles about injection molding machines, hot runner molds and systems recently. I feel that they all talk about a certain…

Selection and application of flame retardants for PBT and PET engineering plastics Flame retardant PBT and PET (linear polyester) PBT and PET are two important…

Intro In fact, in the field of thermoplastic elastomers, overmolding is a special type of overmolding. So what is overmolding? Simply put, overmolding can be…

Introduction Prototype production is primarily categorized into four methods: 3D printing, CNC milling, silicone molding, and hand engraving. Hand engraving dominated the early stages of…

1, Mold hardness: soft mold, hard mold ①Soft mold: The mold steel has been pre-hardened and does not require quenching treatment, but the hardness is…

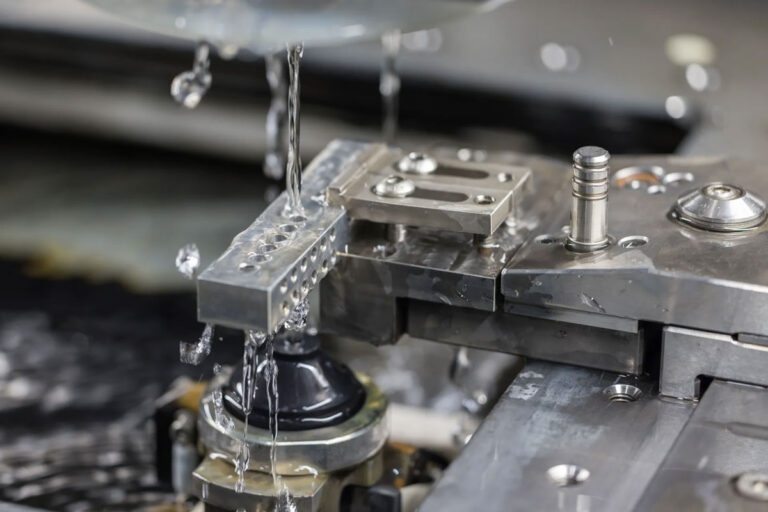

Intro In fields such as high-end molds, aerospace, and precision electronics, many parts require high hardness, complex structures, extremely small tolerances, and a high degree…

How does primary injection work? When using one-stage injection molding in plastics, high pressure and high speed injection can quickly fill the mold cavity, but…

1, Compression injection molding Compression injection molding is a more traditional injection molding method Principle: First, the molten material is injected into the mold cavity….

What Is Plastic Shrinkage? Plastic shrinkage refers to the percentage difference between the dimensions of a plastic part at molding temperature and after it is…

1, Electrospark machining 1) Basic principles Electrospark machining is a special machining method that uses the electro-erosion effect generated by pulse discharge between two electrodes…

What Is Gantry Machining A gantry machining center is a large-scale machining center in which the axis of the spindle Z-axis is arranged perpendicular to…

This is a detailed guide from basic concepts to advanced knowledge to help you understand CNC programming systematically. What is CNC programming? CNC (Computer Numerical…