Intro

The two mold production processes introduced today produce products that are everywhere in our lives, namely injection molding and blow molding.

They have their own characteristics. Blow molding adopts the “injection + blowing” method, and injection molding adopts the “injection + pressing” method. Injection molding is a solid core, and blow molding is a hollow core .

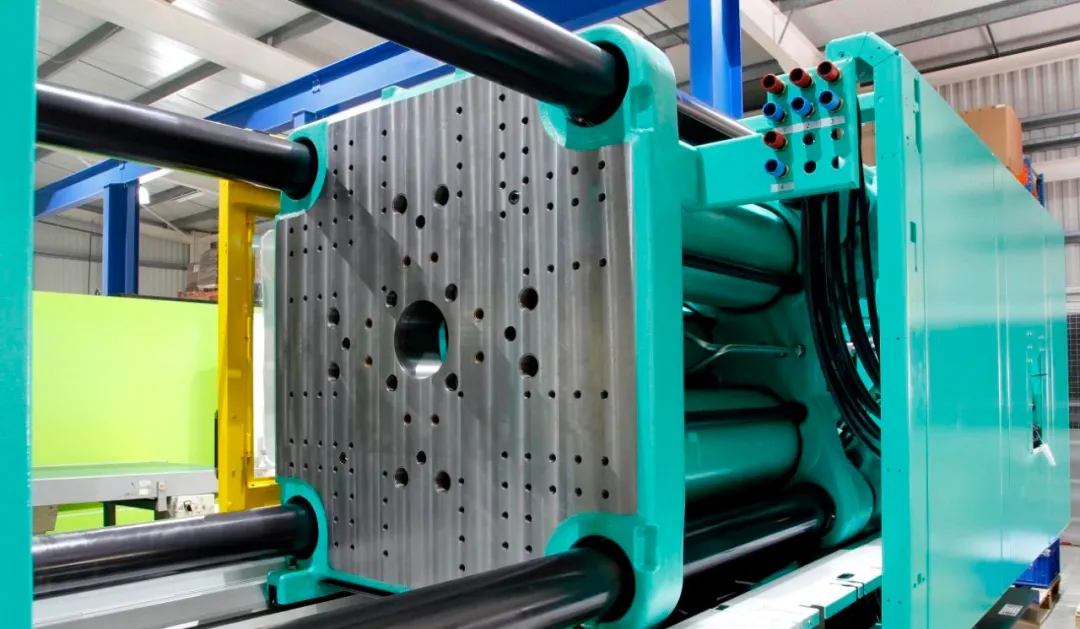

Injection molding

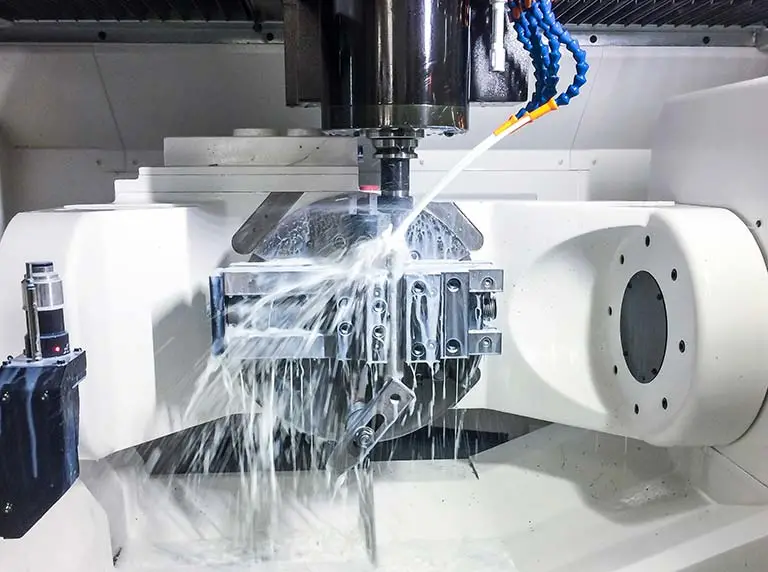

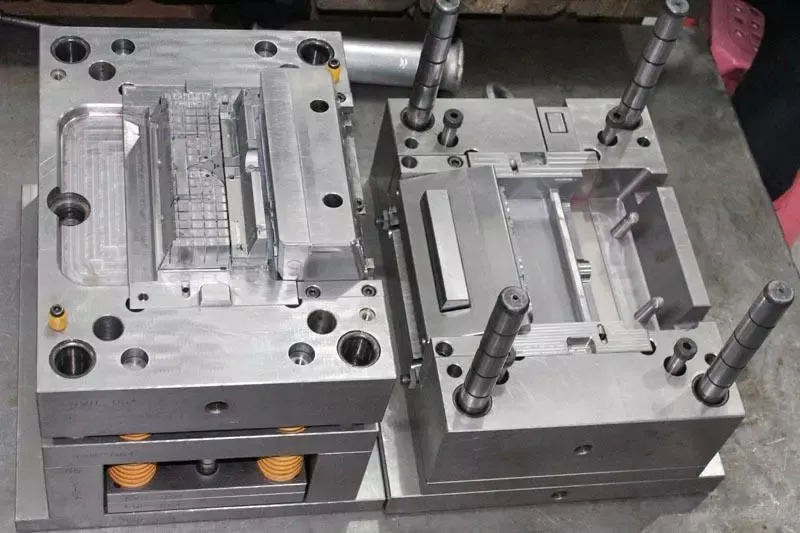

Let me first introduce the injection mold. It is used to perform injection molding on materials, that is, the plastic material is melted and then injected into the mold cavity. After cooling, it is processed into the required shape.

The resulting shape is the final appearance of the finished product and no further processing is required.

In addition, the injection molding process allows for fine control of details, and protrusions, threads, and other parts can be molded in one step during the injection molding process.

Blow molding

Next is blow molding, a rapidly developing plastics processing method also known as hollow blow molding. The Coca-Cola bottle we released earlier was blown out, using the blow molding process.

You can watch the video to understand the process more intuitively.

Its processing principle:The thermoplastic resin or tubular plastic blank obtained by injection molding is placed in a mold, and then compressed air is injected into the mold after the mold is closed to inflate the plastic blank and close to the inner wall of the mold , and then the desired hollow product is obtained by cooling and demolding.

Very similar to blow molding of hollow products, the manufacturing process of blown film is in principle produced without the use of molds, which is completely different from injection molding.

According to the blank production method, blow molding can be divided into extrusion blow molding and injection blow molding. The new development direction is multi-layer blow molding and stretch blow molding.

The difference between the two

Intuitively, the main difference between injection molds and blow molds is the form of the product . Products made by injection molding are usually thicker, relatively simple to manufacture, and have relatively low requirements for raw materials.

The blow molding process is different, and the product is thin and transparent. Because of this, there are certain requirements for the toughness and tensile properties , and the processing requirements for blow molding molds are also relatively high.

Injection molds and blow molds are widely used in daily life, and both have their own advantages and characteristics, and their development prospects are good.