Why Can Rapid Mold Save Time Compared With Traditional Mold?

Intro Due to market uncertainty, more and more companies are choosing rapid tooling to pilot new products. Many project investors often ask me: Why does…

Intro Due to market uncertainty, more and more companies are choosing rapid tooling to pilot new products. Many project investors often ask me: Why does…

Introduction Fasteners serve as the backbone of mechanical connections. Their surface treatment not only impacts their appearance but also directly determines their corrosion resistance, wear…

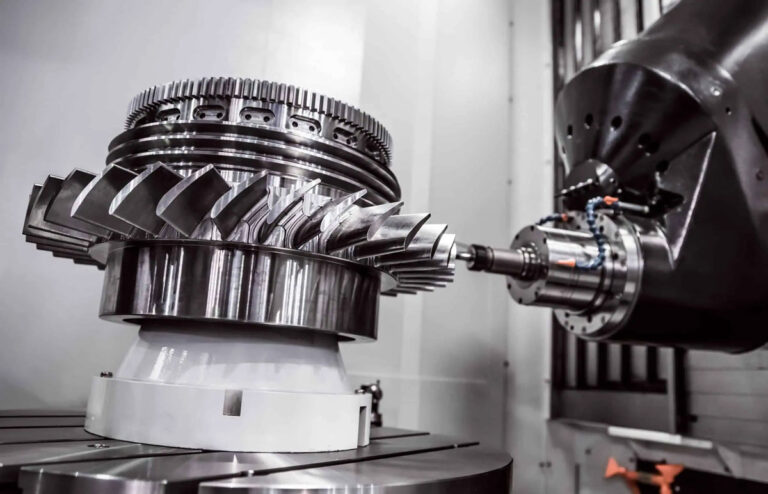

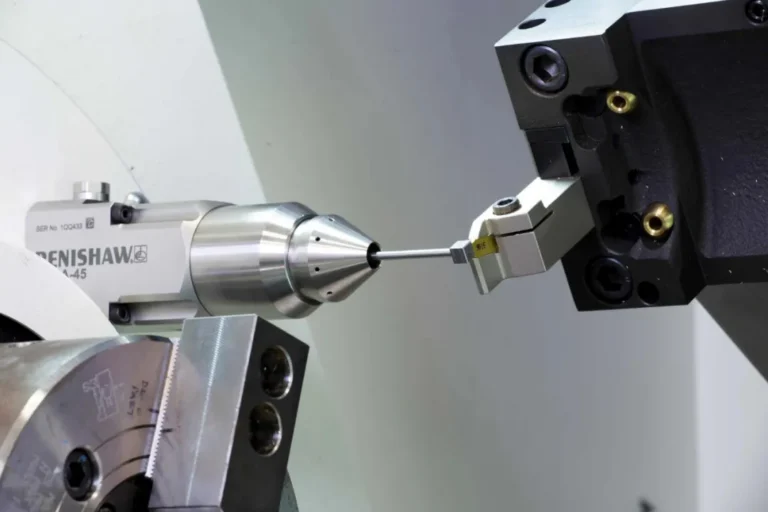

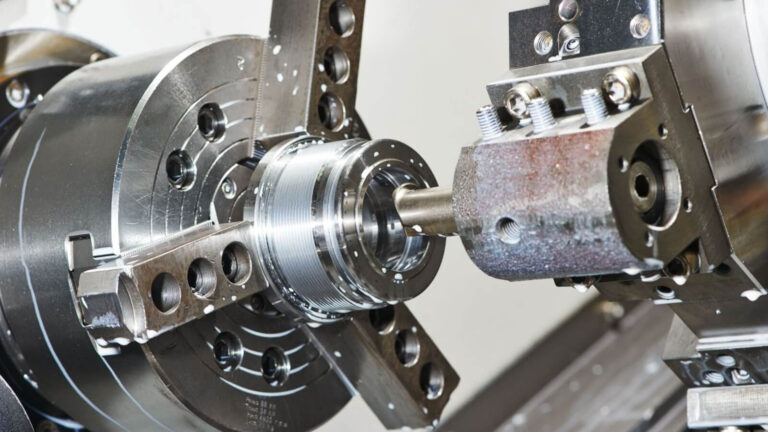

What Is Machining accuracy? Machining accuracy is the degree to which the actual size, shape, and position of the machined part surface conform to the…

Introduction We all know that CNC prototype processing has high precision and can accurately control product quality. Coupled with high production efficiency, it has become…

Introduction Because of its unparalleled efficiency and accuracy, CNC machining is an indispensable part of modern manufacturing. The processed components find application in almost every…

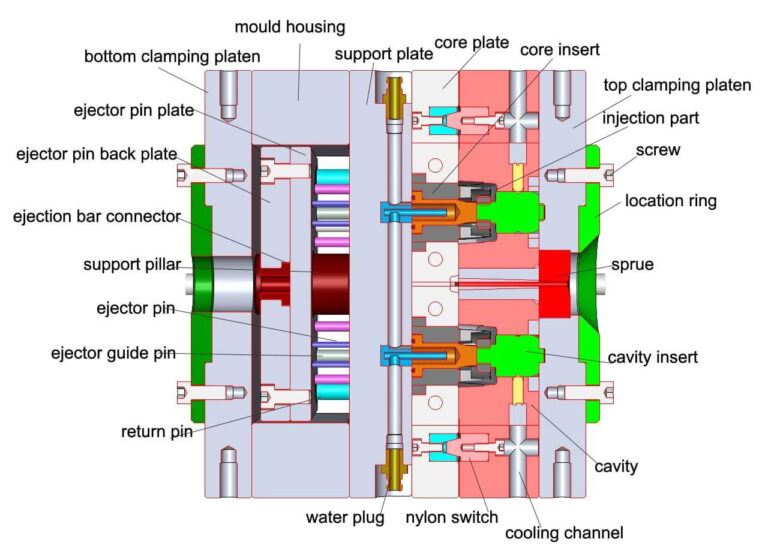

Introduction A reliable plastic mold design is mainly reflected in the quality of the molded plastic products (appearance quality and dimensional stability), convenience, speed and…

Introduction Color shading is a common defect in injection molding. It’s not uncommon for entire batches of injection molding machines to be scrapped due to…

Intro PVC is inexpensive, inherently anti-inflammatory, and strong, with excellent chemical resistance and a shrinkage rate of 0.2-0.6%. It is increasingly used in electrical appliances,…

Intro Mechanical design is the first step in mechanical production and the primary factor in determining mechanical performance. To meet the high performance demands of…

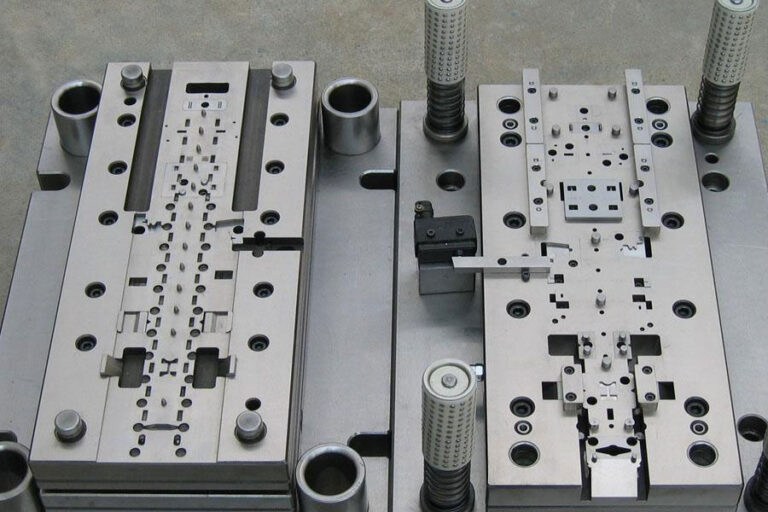

Introduction Many customers may think that developing an injection mold is a simple task and wonder why the price is so high. In fact, injection…

Introduction In the production of plastic products, 3D printing and injection molding are relatively common processes. One of the advantages of 3D printing over injection…

Introduction Injection molds, stamping molds, and die-casting molds are three common types of molds in industrial production. Their working principles, applicable materials, and production scenarios…

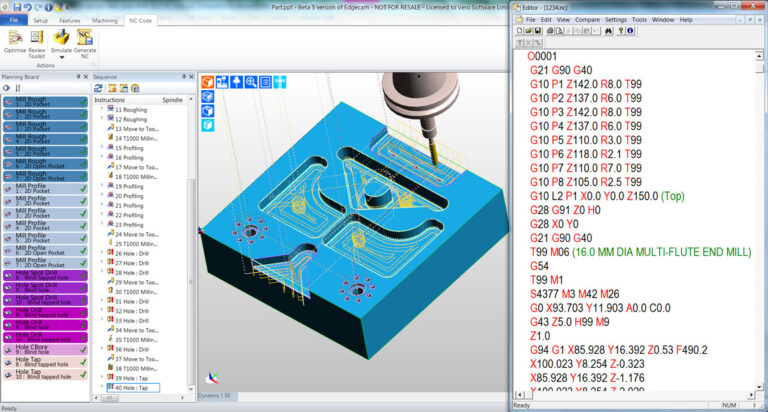

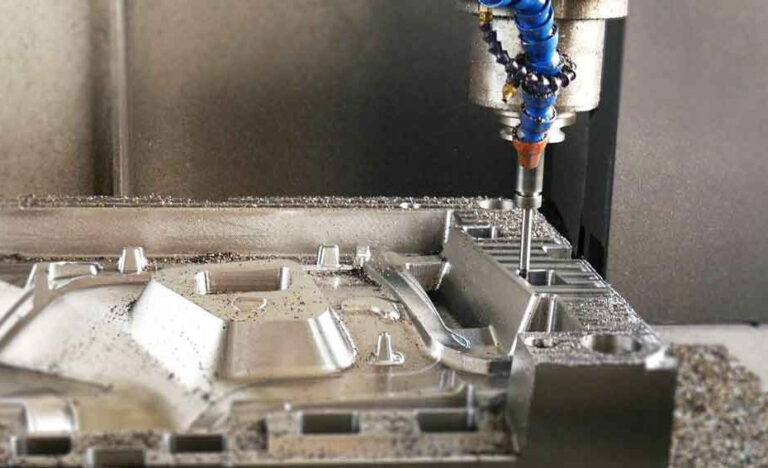

When designing a part, it is best to consider in advance which process will be used to manufacture the model and optimize it accordingly. Among…

When injection molding PFA (fluoroethylene propylene, a fluoroplastic), special attention should be paid to its high-temperature processability, poor fluidity, and easy decomposition. The following is…

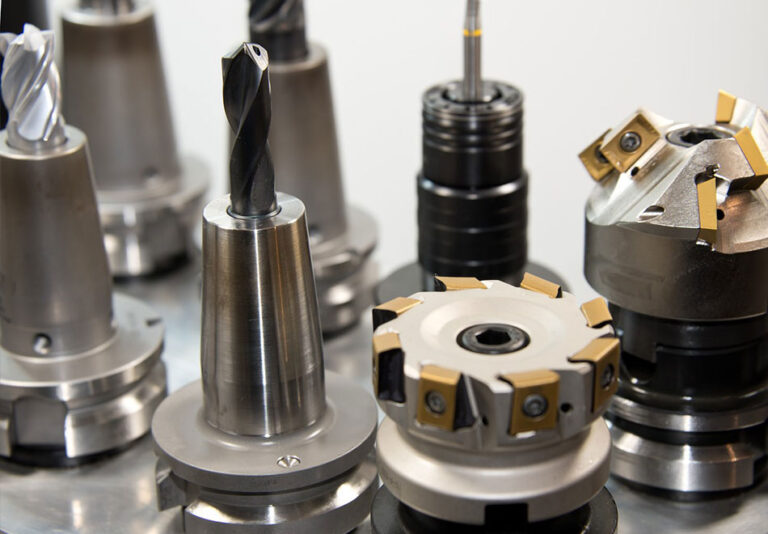

The importance of tool selection in machining is self-evident. Learning to choose tools can help you work more easily. Therefore, you must pay attention to…