Common Fixtures For CNC Machining

Today, Gaofeng will introduce to you some of our most common fixtures for CNC maching , hoping it can help you. 1, Chuck The chuck…

Today, Gaofeng will introduce to you some of our most common fixtures for CNC maching , hoping it can help you. 1, Chuck The chuck…

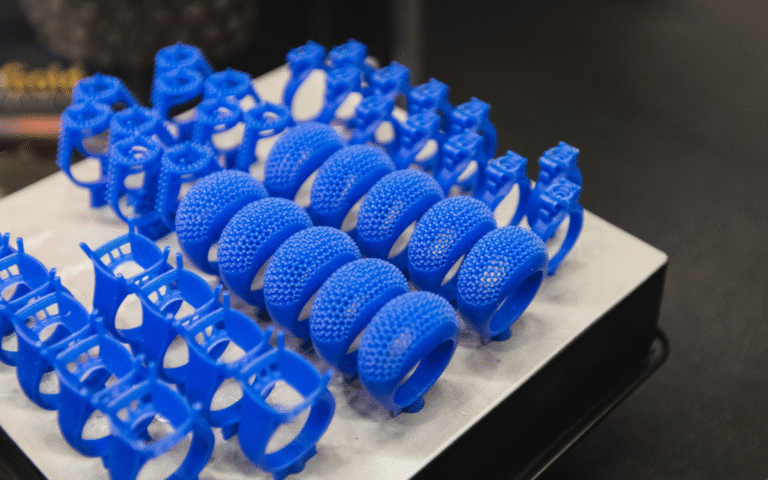

Intro In the product development process, rapid prototyping (or prototyping) is a critical bridge between conceptual design and mass production. It not only verifies a…

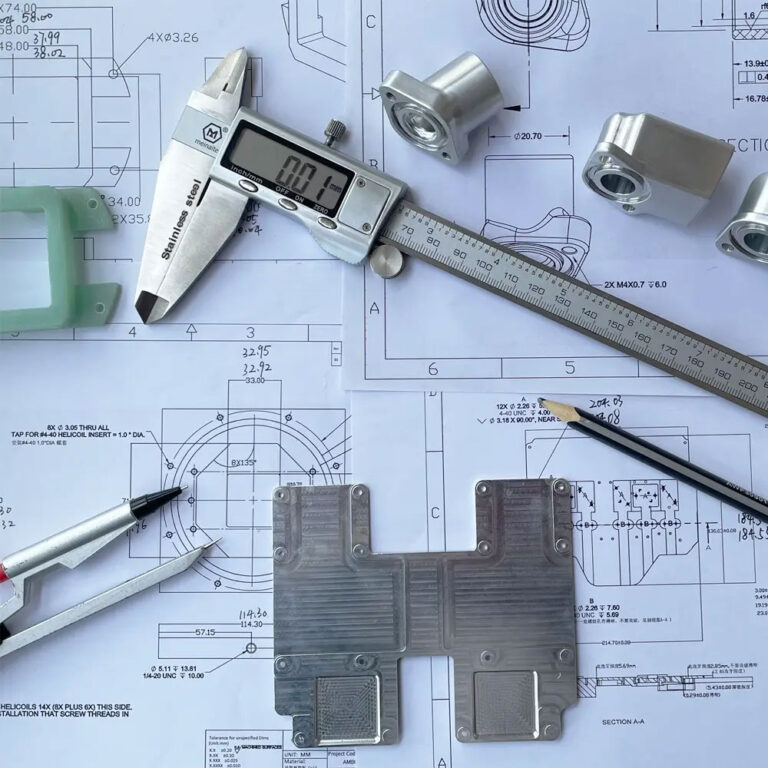

1.What is Design for Function (DFM)? The full name is “Design For Manufacturing”, which means “parts processing-oriented”. Through process feature design, the difficulty of part…

During the critical stage of product development, prototype production is a key step in verifying design feasibility. As a professional manufacturer with 15 years of…

Introduction With the continuous development of science and technology, the manufacturing industry is also ushering in a wave of innovation. Among them, titanium alloy 3D…

With the development of technology, our technical personnel have invented a variety of products for us to use. In order to adapt to the development…

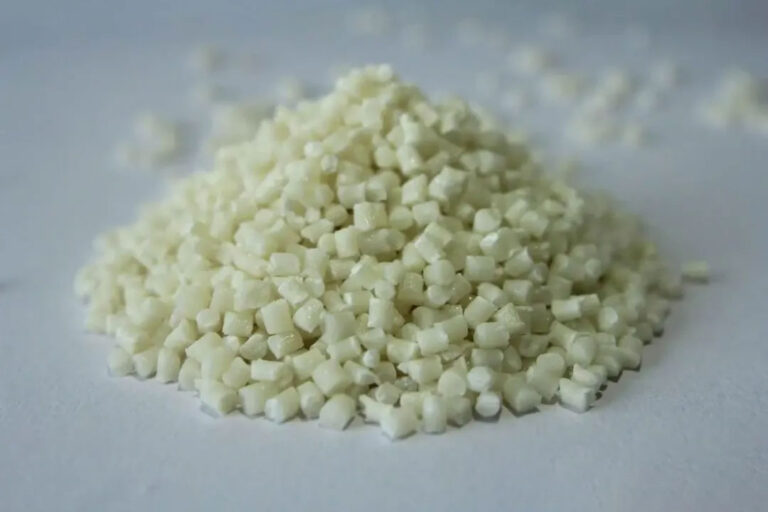

Brief Intro FDM 3D printing is one of the most widely used 3D printing technologies, and basically all FDM 3D printers use PLA and ABS…

Galvanized Features Zinc is relatively stable in dry air and is not easy to change color. In water and humid atmosphere, it reacts with oxygen…

Hello everyone! Today we’ll discuss two common surface treatment techniques used in industry—sandblasting and shot peening. While their names may sound similar, their functions and…

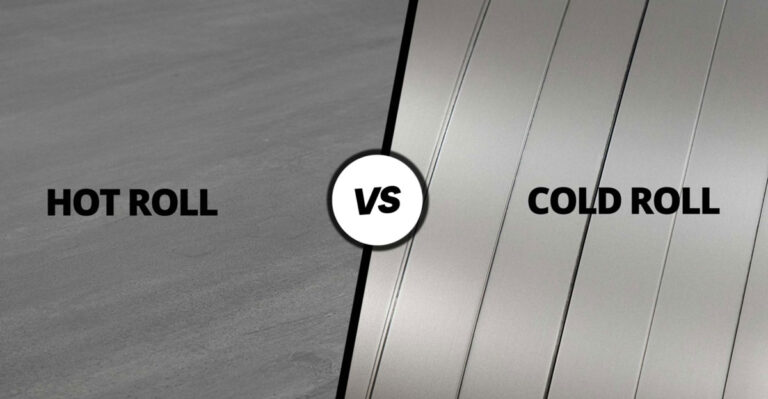

1. Different colors The surface of cold-rolled sheet is oily and silvery white, almost the same as stainless steel. The surface of the hot-rolled plate…

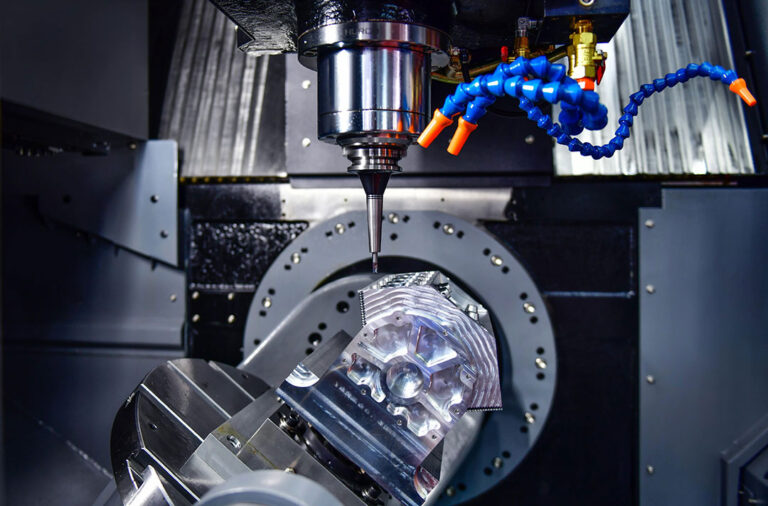

Introduction Each tool uses different processing parameters based on the material being processed. In the field of milling, tool manufacturers aim to improve processing efficiency…

The basic principle of fusible core injection molding is to first use a low-melting-point alloy to cast a fusible core, then place the fusible core…

Production workshop The layout of the production workshop focuses on two aspects: meeting production demand conditions, optimizing the layout according to the production process, and…

Wrong speed = tool wear. Wrong feed rate = noise, burns, scrap. Recommended feed per tooth Tool diameter Aluminum alloy (mm/tooth) Steel (mm/tooth) Stainless steel…

Intro We can see a variety of materials in our daily lives. Some are familiar, while others are so closely related to our lives that…