TPU Injection Molding Process Guide

Injection molding machine TPU materials can be molded using standard screw injection molding machines, and plunger injection molding machines are also suitable. However, for larger…

Injection molding machine TPU materials can be molded using standard screw injection molding machines, and plunger injection molding machines are also suitable. However, for larger…

Introduction The cost code of sheet metal design: systematic strategy and refined practice to create the ultimate cost-effectiveness In today’s highly competitive manufacturing environment, product…

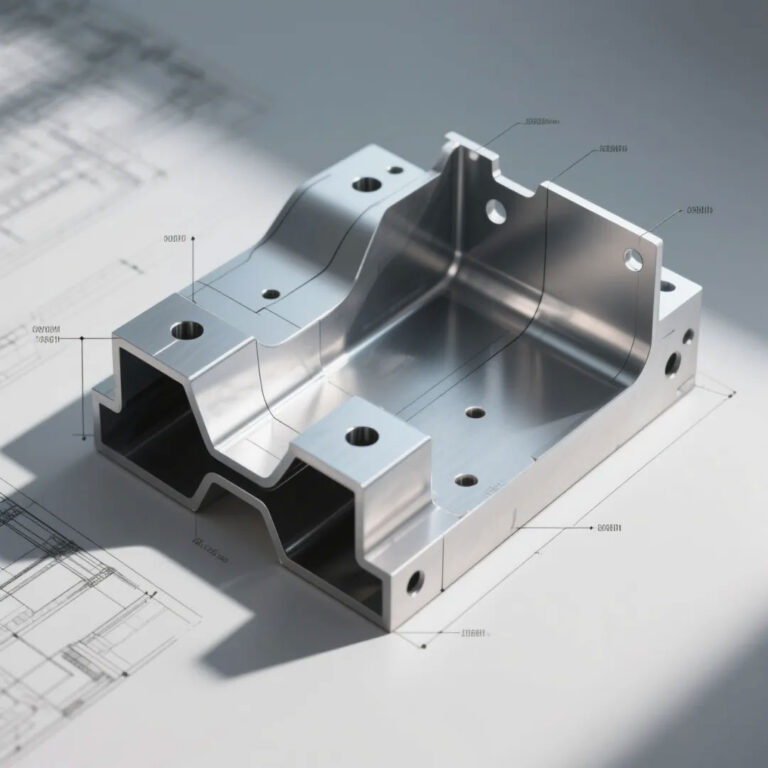

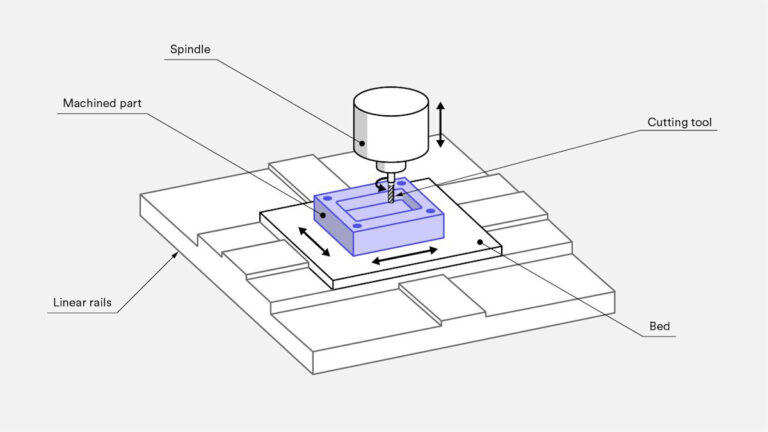

Introduction In modern machinery manufacturing, controlling part machining accuracy is a key factor in maintaining product quality and improving production efficiency. Machining accuracy not only…

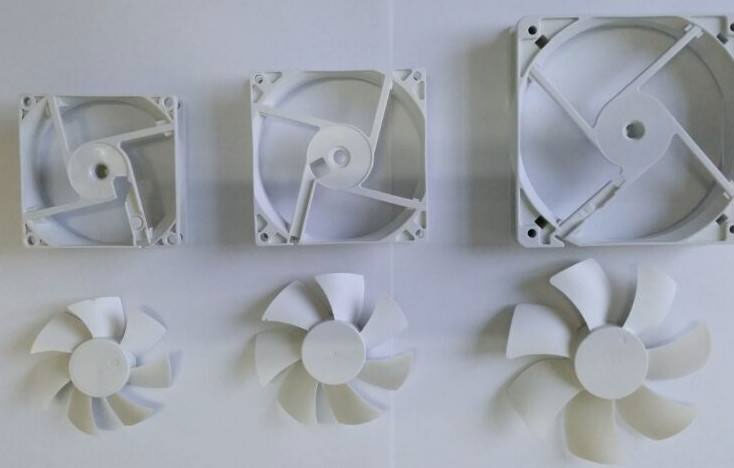

Short Intro The plastic raw material processing process mainly involves the melting, flowing, shaping and cooling of the rubber particles into finished products. It is…

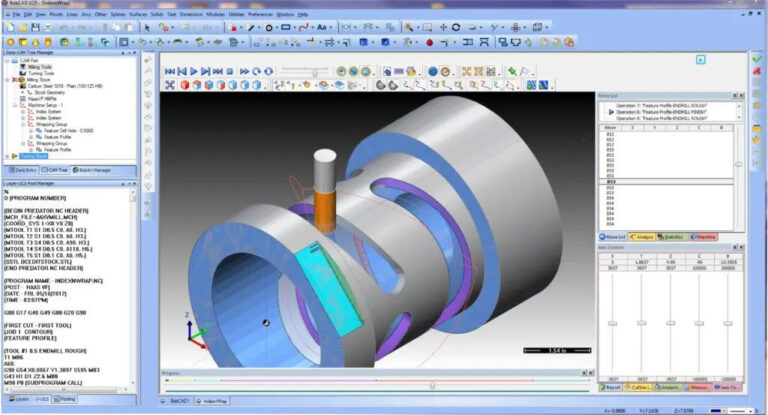

Brief Intro The programming methods of CNC machining centers (CNC) are mainly divided into the following categories. Each method is suitable for different processing requirements…

Introduction POM (also known as Saigang and Trane) is obtained by polymerizing formaldehyde and other raw materials. POM-H (polyoxymethylene homopolymer) and POM-K (polyoxymethylene copolymer) are…

Introduction When searching for injection mold suppliers, many customers find that quotes from different manufacturers vary greatly, sometimes even by several times. Why does this…

In the production process of silicone products, demoulding is a crucial step, but it is often difficult to demould the molded parts, which not only…

Glass fiber reinforced plastics are made by adding glass fiber and other additives to the original pure plastic to increase the range of material applications….

1, Adjustment of the parallelism of the guide rails in the mold clamping part Use a precision spirit level to make rough longitudinal adjustments on…

Molding performance of PBT 1) PBT has low hygroscopicity, but it is sensitive to moisture at high temperatures. During the molding process, the PBT molecules…

Generally speaking, contact seals have good sealing performance, but are limited by friction and wear, and are suitable for occasions with low sealing surface linear…

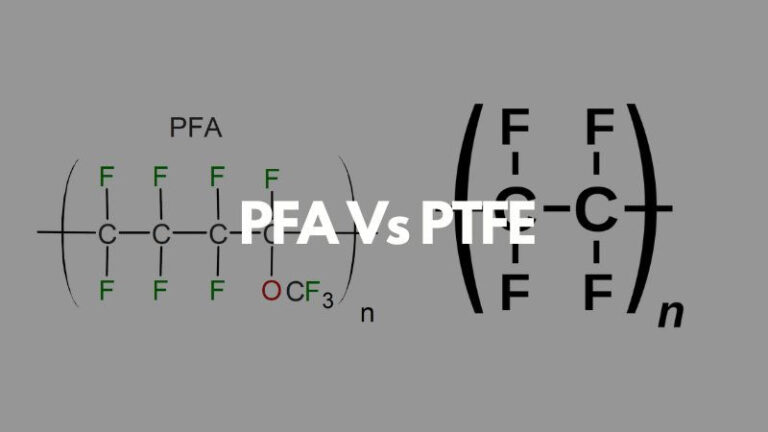

The first is the difference in chemical structure: PFA incorporates a perfluoroalkoxy group, which is equivalent to replacing a fluorine atom in PTFE with a…

Introduction If designers want to make good use of CNC processing, they have to design according to the processing rules, but there is no unified…

Introduction Turning is a machining method that creates a desired shape by removing material, and is classified as cutting. Turning processes can achieve complex shapes…