The Development And Application Of Laser Welding Technology

What is laser welding? Simply put, laser welding is to heat the surface of the workpiece with laser radiation, and the surface heat diffuses to…

What is laser welding? Simply put, laser welding is to heat the surface of the workpiece with laser radiation, and the surface heat diffuses to…

Today, the editor has compiled some knowledge about surface treatment technology for prototyping, hoping it will be helpful to you. 1.Screen printing Screen printing involves…

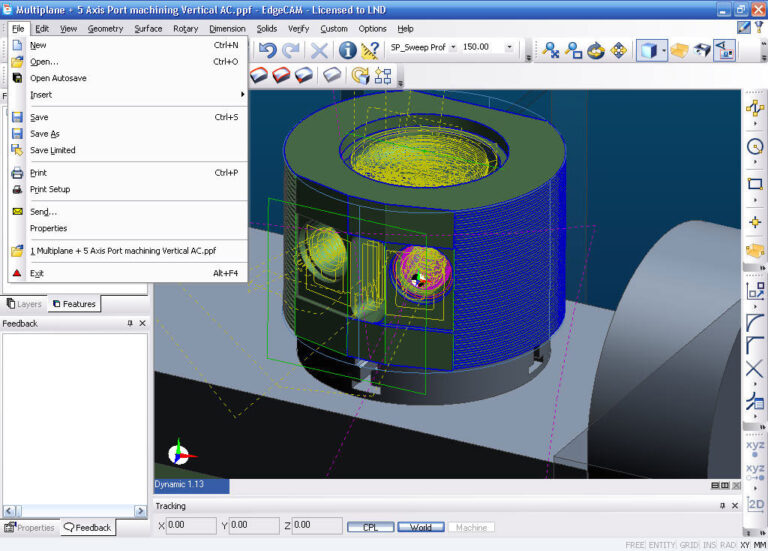

Introduction With the advancement of technology, CNC machining has placed higher demands on part complexity, precision, and craftsmanship, making traditional manual programming inadequate. Consequently, CAM…

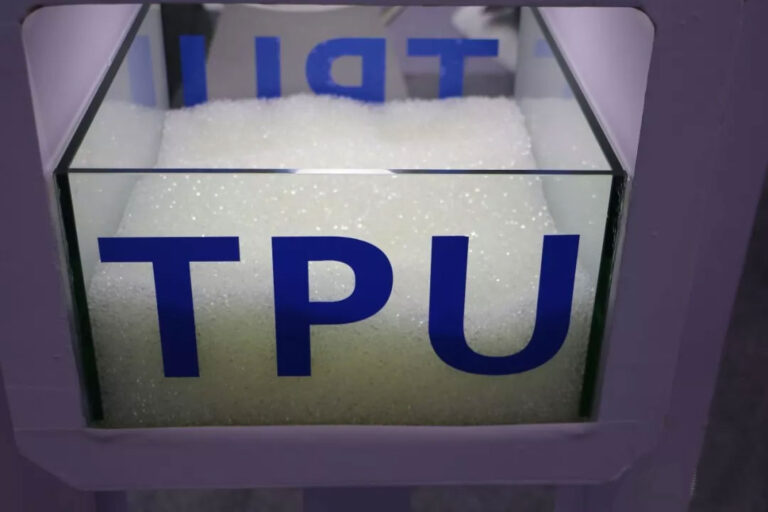

Introduction In a broad sense, TPE refers to the general term for all thermoplastic elastomers, including: SBS, SEBS, SIS, SEPS, TPO, TPV, TPU, TPVC, TPEE,…

What is the difference between liquid silicone and solid silicone? 1.Liquid silicone Liquid silicone is relative to solid high-temperature vulcanized silicone rubber. It is a…

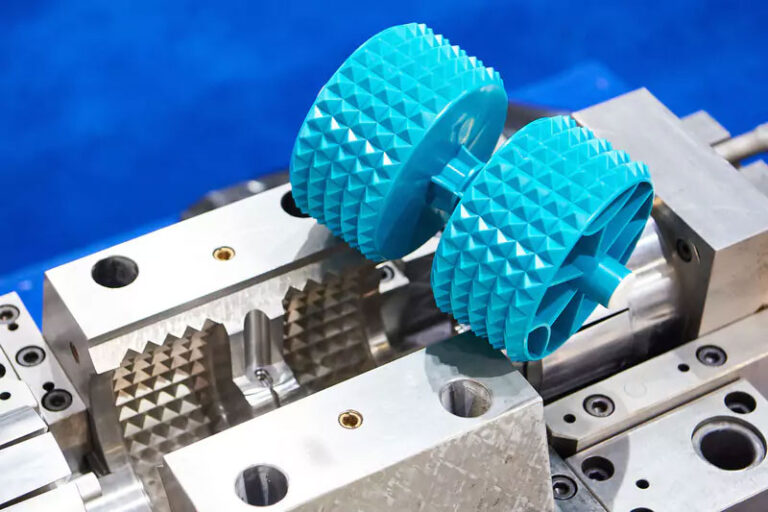

Silicone Molding Silicone molds are suitable for trial production of smaller batches (20-30 pieces), especially in the new product development stage. The molds are made…

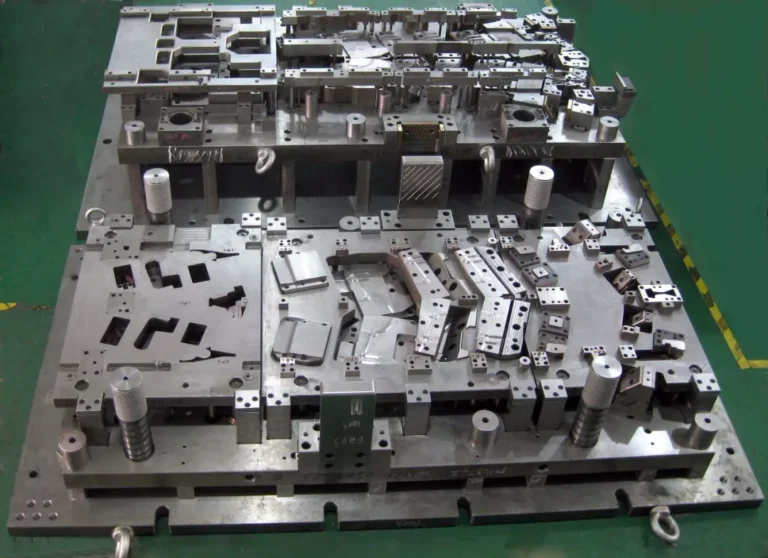

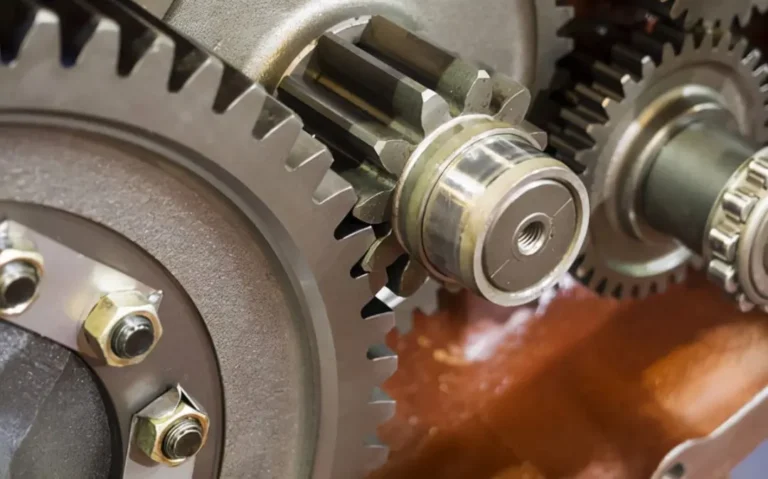

Introduction of stamping dies Stamping dies, also known as cold stamping dies, are specialized equipment used during the cold stamping process to process materials into…

Introduction As the market demand for machining increases, the technical precision of machining also increases, and the types of machine tools become more and more…

Introduction Wire drawing is a common surface treatment technology, which is mainly used in metal products, but is also applicable to plastic and other products….

Prototyping is an essential step in the product development process, but high processing costs often put pressure on companies. As a professional team at Yingshuo…

Intro During the manufacturing process, metal parts undergo a series of processing techniques, such as grinding, drilling, milling, turning, tapping, grooving, etc. After processing, it…

When making prototypes, some customers choose electroplating, while others opt for painting. What are the differences between these two processes? And how should we choose…

1.Analyze the client’s information. After receiving a prototype production order, we first analyze the client’s information to determine the materials required, the desired prototype effect,…

What Is Anodizing? Aluminum anodizing is an electrolytic oxidation process in which aluminum and its alloys form an oxide film on the aluminum product (anode)…

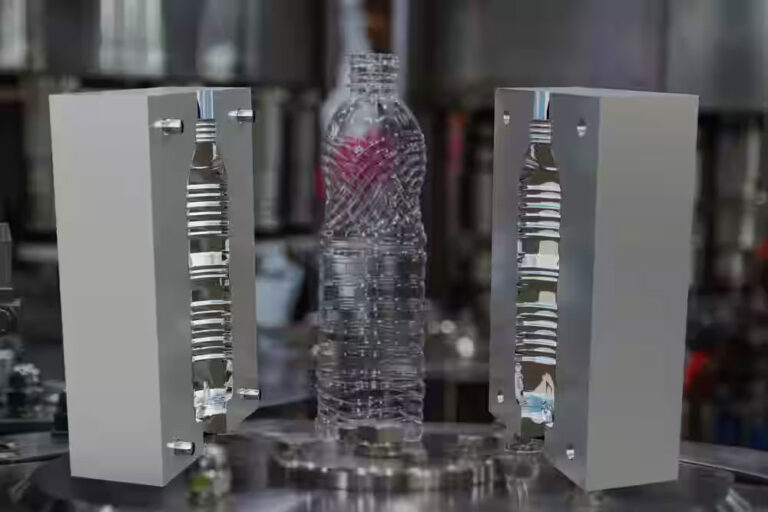

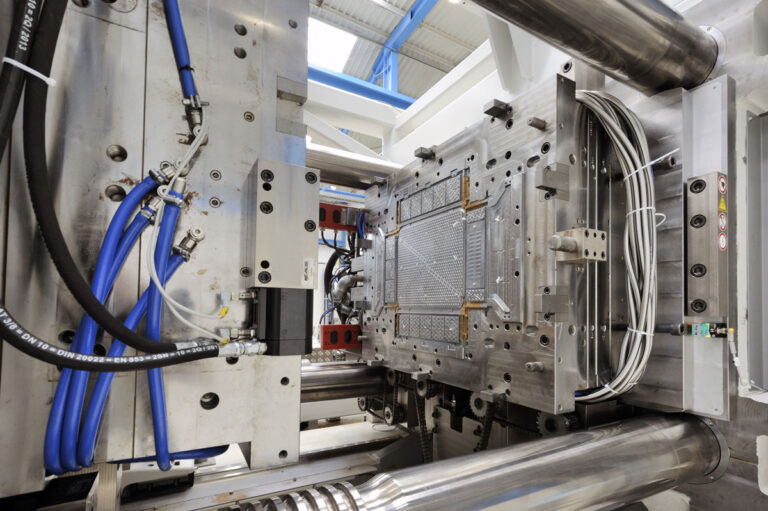

Introduction In injection mold manufacturing, the choice of steel is crucial and needs to be considered comprehensively based on the characteristics of the plastic, product…