Introduction of stamping dies

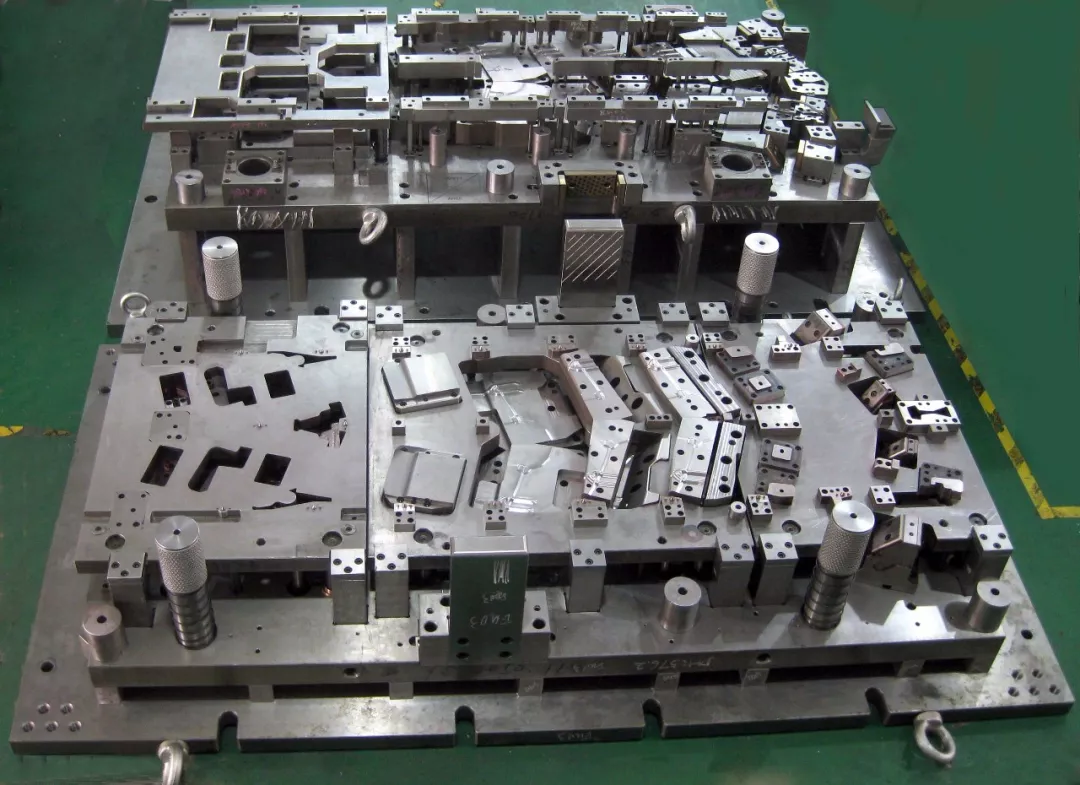

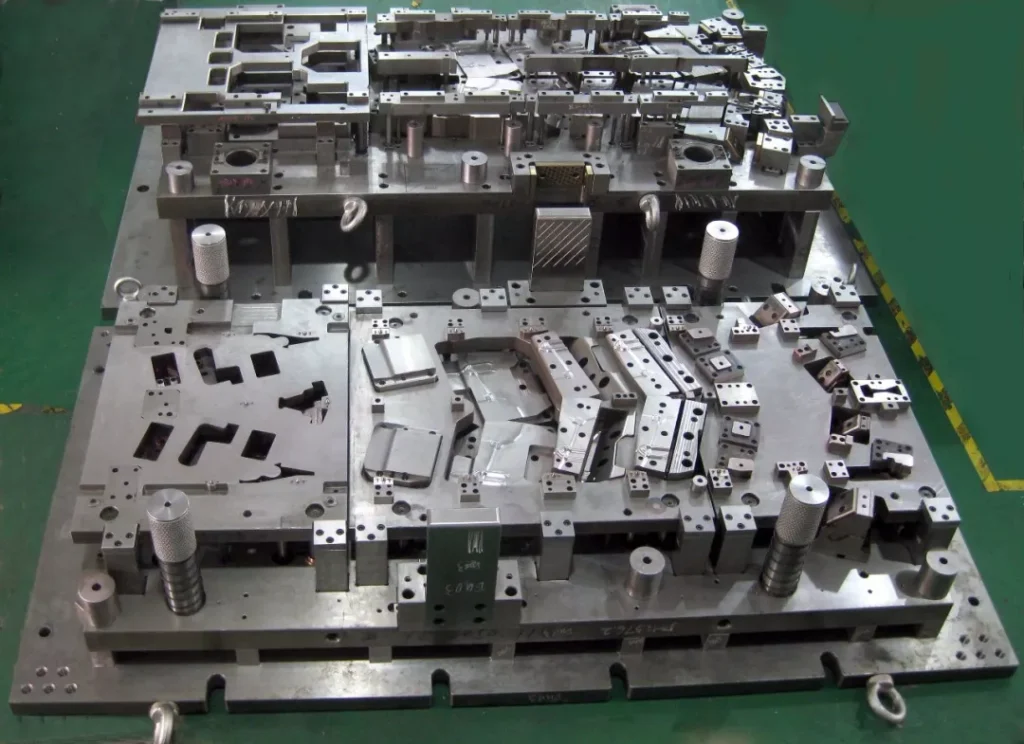

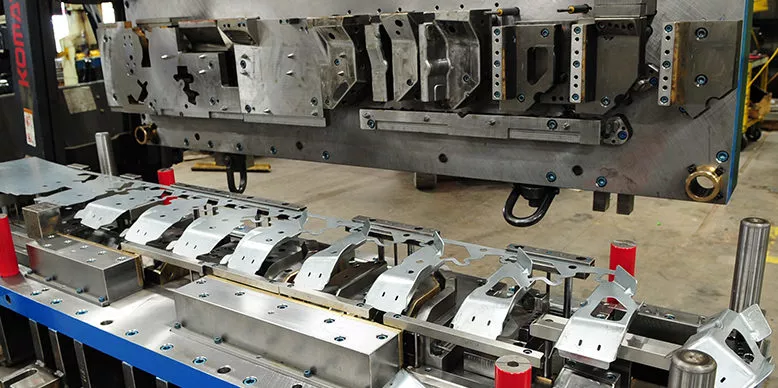

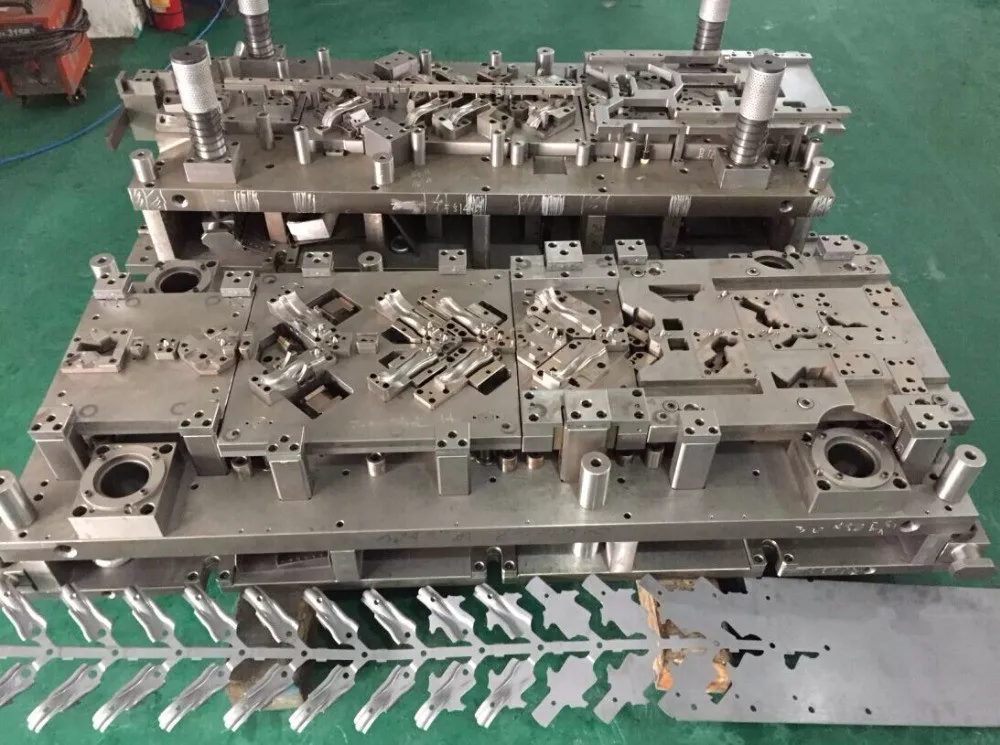

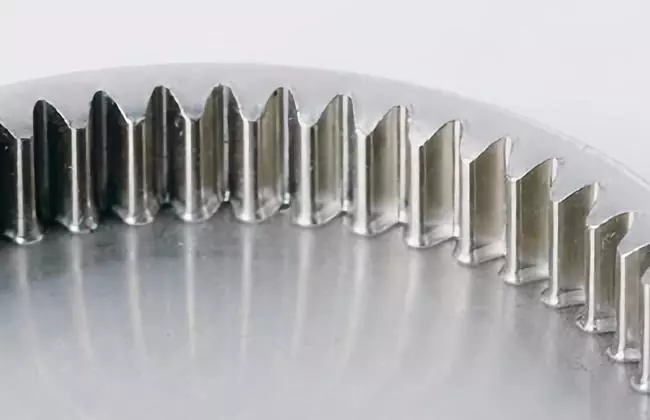

Stamping dies, also known as cold stamping dies, are specialized equipment used during the cold stamping process to process materials into parts or semi-finished products. The materials can be either metallic or non-metallic. Stamping is a pressure processing method performed at room temperature. A die is installed on a press and applies pressure to the material, causing it to separate or plastically deform, ultimately yielding the desired part.

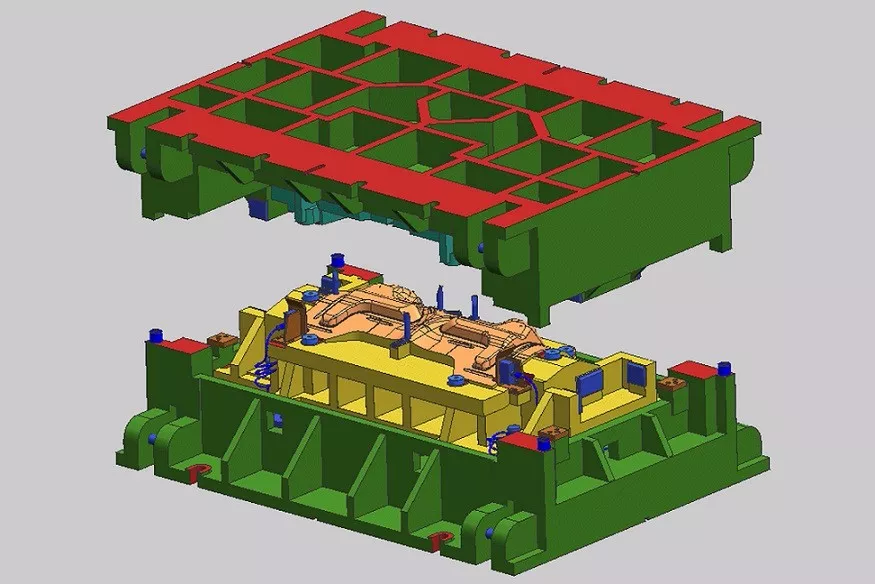

Stamping process design and die structure design are two aspects of stamping die structure design. In the production process of stamping parts, stamping process design is mainly applied. It mainly includes the process plan, how to arrange, the size of the process, what equipment and die type to use, as well as various technical and economic indicators. The comprehensive overall planning of these aspects is the process of stamping process design. Stamping die structure design is to design the specific structure and shape of the required die according to the various requirements of the above stamping process design, and also draw the die assembly drawing and die parts drawing.

Material selection for stamping die design

Stamping die materials

Materials used to make stamping dies include steel, cemented carbide, steel-bonded cemented carbide, zinc-based alloys, low-melting-point alloys, aluminum bronze, and polymer materials. Currently, the vast majority of stamping dies are made of steel, and commonly used materials for die working parts include carbon tool steel, low-alloy tool steel, high-carbon and high-chromium or medium-chromium tool steel, medium-carbon alloy steel, high-speed steel, matrix steel, cemented carbide, and steel-bonded cemented carbide.

Selection principles of stamping die materials

The materials used in stamping dies can be various metal materials or various non-metallic materials. These two types of materials mainly include carbon steel, alloy steel, cast iron, cast steel, cemented carbide, low melting point alloy, zinc-based alloy, aluminum bronze, synthetic resin, polyurethane rubber, plastic, laminated birch board, etc.

The materials used to manufacture molds also have stringent requirements. Not only must the material possess high hardness, strength, and wear resistance, but it must also possess appropriate toughness, high hardenability, and properties such as resistance to deformation during heat treatment and cracking during quenching. To ensure the mold’s longevity, it is essential to rationally select the mold material and correctly implement the heat treatment process. Choosing the right steel grade and heat treatment process should correspond to the mold’s different uses. Furthermore, the selection should be based on a variety of factors, including its operating conditions, stress conditions, the properties of the material being processed, production batches, and productivity, with particular emphasis on the various properties described above.

Structure of stamping die

Structural composition of stamping die

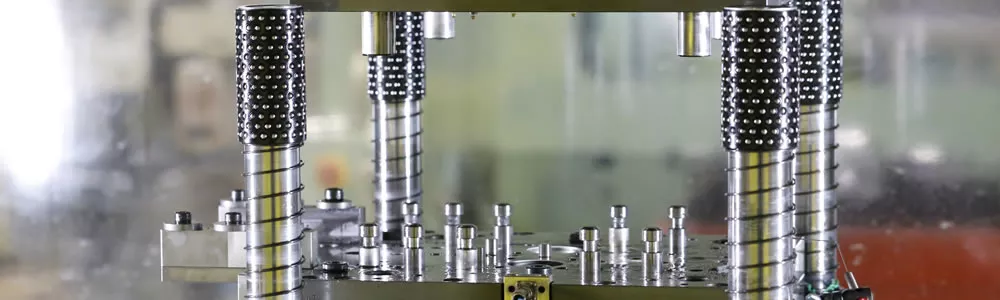

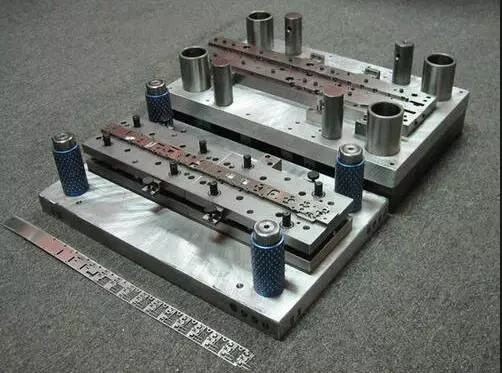

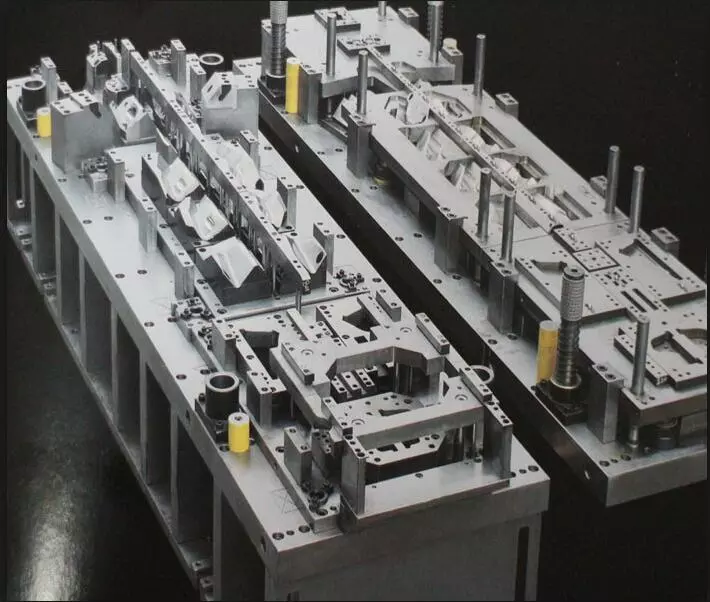

Based on the role of the mold in its structure, the mold’s structure is mainly composed of process parts and structural parts. Process parts are directly involved in the process and continue until it is completed. They are also in direct contact with the blank. Process parts mainly include positioning parts, working parts, unloading parts and pressing parts. However, structural parts are completely different from process parts. They do not directly participate in the process and do not have direct contact with the blank. They only play a role in ensuring the completion of the process or improving the function of the mold. Structural parts mainly include fastening parts, guide parts, standard parts and some other parts. However, it should be noted that not all stamping dies must contain these six parts.

Basic principles of stamping die design structure

Safety Principles

Safety is the primary consideration when designing a stamping die. Accidents caused by errors in die design must be avoided. Even the actual operators of the die must not put themselves in a dangerous situation. During the die design process, the safety of the operator must be ensured. The die must also possess a certain level of strength during processing.

Basic requirements

The structural frame must have a uniform thickness; the thickness of the working part of the mold must be uniform and not too thin; the design of the stamping die must meet the bearing capacity standards; the quality of the structure of the stamping die must be balanced; the material of the stamping die structure frame and the material of the working part must also be carefully selected, as these are prone to wear, so the cost must be carefully calculated; the bearing capacity of the stamping die structure; the structure of the parts is best measured by calculation.

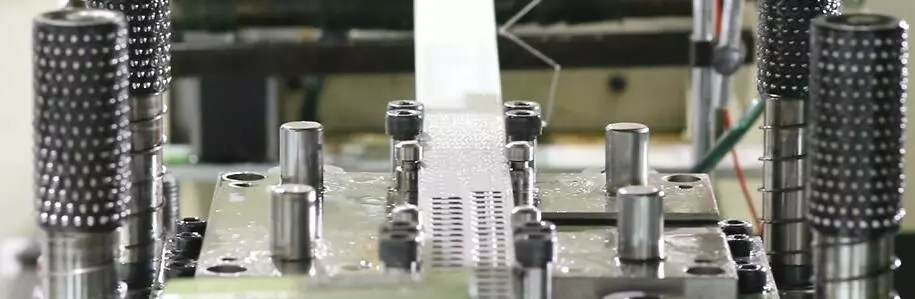

Before determining the structure of the stamping die, it is necessary to first determine the feeding method and unloading method of the stamping die, as well as the form of the stamping die frame.

Design of stamping die

Determination of stamping gap

The stamping clearance refers to the difference in size between the punch and concave edges of the stamping die. The size of this clearance has a significant impact on the quality of the single-sided stamping part, the amount of stamping force, and the service life of the die.

Therefore, one of the important process parameters in stamping die design is the stamping clearance. Therefore, when designing the die, it is important to select an appropriate stamping clearance to ensure the quality of the stamped part, maintain a low stamping force, and ensure the service life of the die.

The appropriate clearance value has different standards based on different data. As long as the selected stamping clearance is within the appropriate range during production, it is sufficient. Within this appropriate range, the minimum value is called the minimum reasonable clearance value, and the maximum value is the maximum reasonable clearance value.

During the use of the die, the die may also wear, causing the clearance to increase. Therefore, the minimum reasonable clearance value should be used when designing a new die.

Determine the dimensions of the concave and convex dies

The working edge dimensions of the punch and concave dies of a stamping die require careful calculation.

1) The die structure of the die should be manufactured according to the needs of the part, and the manufacturing method should be based on the above description. The die is generally fixed directly to the punch.

For example, how to determine the thickness of the die in the manufacturing process of the punching die. The thickness of the die refers to the length from the die cutting edge to the outer edge.

Therefore, the empirical formula for the die’s outer dimensions is generally used to determine the die’s outer dimensions, that is, H=Kb (H≥15mm). K represents the coefficient, which can be found in books; b represents the maximum width of the die hole. In the manufacturing process, not only the thickness of the die must be calculated, but also the related data around the die. In this way, a suitable die structure combination is formed with the already determined main structure of the die. This greatly simplifies the mold design.

2) The punch die’s structure is also tailored to the needs of the stamped part, and its fabrication method is based on the data generated by the count. The punch is typically secured with rivets, but low-melting-point alloys or welding agents are also acceptable. Then, simply assemble the die and punch, along with other related components, according to the drawings.

Future development trend of stamping dies:

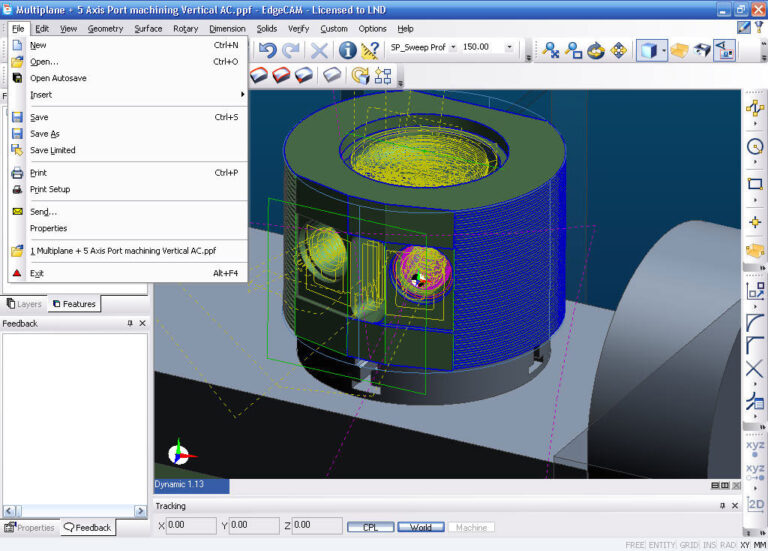

The future development of stamping die technology should be based on the standards of “fast delivery,” “high precision,” “high quality,” and “low price.” How can this be achieved? Meeting these standards requires the timely development of several key areas: Vigorously promoting CAD/CAM/CAE technology for die design. CAD/CAM/CAE technology for die design can be considered the future trend in die design. With the continuous development and advancement of microcomputer software, the conditions have matured for the widespread adoption of CAD/CAM/CAE technology. Die manufacturing industries and businesses will also intensify their efforts in CAD/CAM training and service development, further expanding the application of CAE technology.

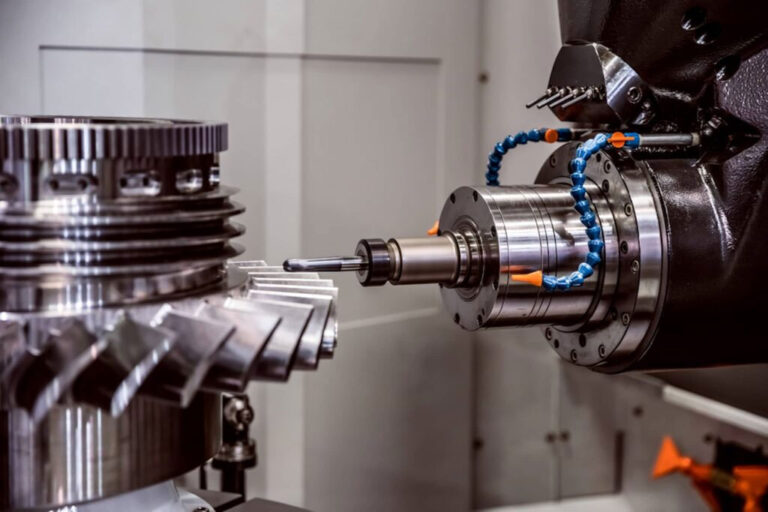

Speeding up milling. The rapid development of the milling industry abroad in recent years has significantly improved processing efficiency and achieved exceptionally high surface finishes. Furthermore, machining high-hardness modules offers advantages such as low temperature rise and minimal thermal deformation. The rapid advancement of milling technology has also injected fresh momentum into the manufacturing of cavity molds for the automotive industry and large and medium-sized home appliance industries. Currently, it is moving towards agility, intelligence, and integration.

Scan and digitize molds. High-speed scanners and mold scanning systems provide the numerous functions needed to scan a model or physical object and produce the desired model, significantly shortening the mold development and manufacturing cycle. Some high-speed scanning systems can be quickly installed on existing CNC milling machines and machining centers, enabling rapid data acquisition and automatically generating machining programs for various CNC systems and CAD data in various formats, enabling “reverse engineering” within the mold manufacturing industry. Mold scanning systems have been successfully applied in the automotive, motorcycle, and home appliance industries, and are expected to play an even greater role during the 15th Five-Year Plan period.

EDM milling. Also known as EDM generative machining, EDM milling is a new technology that replaces the traditional use of formed electrodes for cavity machining. It uses a simple tubular electrode rotating at high speed to create three-dimensional or two-dimensional contours, eliminating the need for complex formed electrodes. This is clearly a significant development in the field of EDM forming. Machine tools using this technology are already being used in mold manufacturing abroad, and this technology is expected to continue to grow.

Improve the standardization of stamping dies. The standardization of stamping dies in my country is still in the stage of continuous improvement. Although the coverage rate of stamping die standard parts in my country has reached about 30%, it is still far behind other countries, especially developed countries. At present, the coverage rate of stamping dies in developed countries can generally reach about 80%.

Select high-quality materials and advanced surface treatment technologies. Selecting high-quality materials and applying corresponding advanced surface treatment technologies is essential to extending the life of stamping dies. For example, selecting high-quality steel is crucial. The key to maximizing the performance of stamping die steel lies in optimizing the heat treatment and surface treatment of the die. The future trend in stamping die heat treatment is the use of vacuum heat treatment technology. Developing not only surface treatment technologies for stamping dies but also advanced technologies such as advanced vapor deposition (TiN, TiC, etc.) and ion spraying is crucial.

The grinding and polishing of stamping dies are automated and intelligent. The quality of the stamping die surface has a great impact on the service life of the stamping die, the quality of the appearance of the stamped parts, and other aspects. The research and invention of automated and intelligent grinding and polishing methods replace the current manual operation methods, thereby improving the quality of the stamping die surface. This is also an important development direction for stamping dies in the future.

Developing automated mold processing systems. Developing automated processing for stamping molds can be considered a long-term development goal for my country’s mold industry. Automatic stamping mold processing systems primarily utilize a rational combination of multiple machine tools, equipped with mobile positioning fixtures or positioning plates. They also feature a comprehensive CNC library for tools and tools, a comprehensive CNC flexible synchronization system, and comprehensive quality monitoring and control systems.