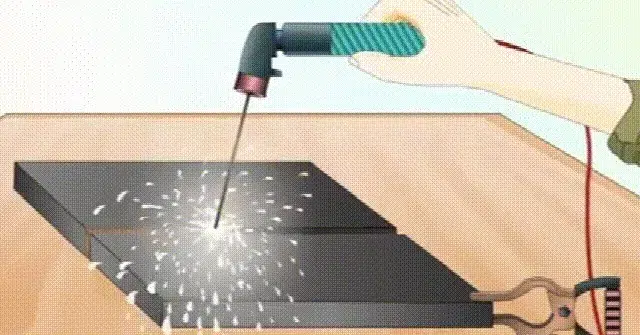

Welding

(1) Connection method

A processing method that achieves atomic bonding between workpieces by applying heat, pressure, or both, with or without filler materials. Common methods include arc welding, resistance welding, and laser welding.

(2) Process advantages

The connection strength is high and can withstand large loads and stresses. It is widely used in automobile manufacturing, mechanical engineering and other fields. For example, the welding of automobile bodies ensures the strength and safety of the body.

Good sealing performance. For sheet metal structures such as containers and pipes that need to be sealed, such as oil tanks and gas tanks, welding can effectively prevent the leakage of liquids and gases.

It has a wide range of applications and can connect various metal materials, including carbon steel, stainless steel, aluminum alloy, etc. It is also suitable for sheet metal parts of different thicknesses and shapes.

(3) Process shortcomings

The high temperature generated during welding may cause deformation of sheet metal parts, affecting their dimensional accuracy and appearance quality, especially for thin sheet metal parts, where deformation problem is more prominent.

Welding may leave weld marks, which require subsequent grinding, polishing and other treatments to improve the appearance, increasing processing costs and time.

The welding quality is greatly affected by the technical level of the operator. When the quality is unstable, defects such as cold welds and leaking welds may occur.

(4) Examples

In the manufacture of automobile bodies, welding processes are widely used to connect various sheet metal components into a whole to ensure the strength and rigidity of the body.

Riveting

(1) Connection method

The method of connecting two or more sheet metal parts together using rivets is divided into solid rivet riveting and hollow rivet riveting.

(2) Process advantages

The riveting process does not require high temperature and will not produce thermal deformation. It is suitable for connecting sheet metal parts with high precision requirements, such as electronic equipment casings, precision instrument components, etc.

The connection speed is fast, the production efficiency is high, it is easy to realize automated production, and it is suitable for the needs of large-scale production.

The riveted connection points have a certain degree of elasticity, which can absorb vibration and impact to a certain extent and improve the reliability of the structure.

(3) Process shortcomings

Riveted parts increase the weight of parts, which may not be suitable for some products with strict weight requirements, such as sheet metal parts in the aerospace field.

After riveting, rivet heads may be left on the surface, affecting the appearance, and sometimes additional processing such as grinding and capping is required.

The connection strength of riveted joints is lower than that of welded joints, and they may become loose when subjected to large tensile or shear forces.

(4) Examples

Some parts of the car interior, such as the instrument panel frame and seat frame, are often connected using riveting technology to ensure their precision and reliability.

Bolt connection

(1) Connection method

The connection method of fixing sheet metal parts together by bolts and nuts can be divided into ordinary bolt connection and high-strength bolt connection.

(2) Process advantages

It is easy to disassemble and facilitate later repair, replacement and adjustment. It is very suitable for sheet metal structures that require frequent maintenance, such as protective covers of mechanical equipment, door panels of electrical cabinets, etc.

The connection reliability is high, and the strength and stability of the connection can be guaranteed by properly selecting bolt specifications and tightening torque.

The tightness of the connection can be adjusted at any time to adapt to different working conditions and stress situations.

(3) Process shortcomings

The need to process bolt holes on sheet metal parts will weaken the strength of the sheet metal parts, especially around the holes, which may cause stress concentration and reduce the bearing capacity of the structure.

Bolted connections increase the number of parts and assembly workload, and are relatively costly, including the cost of parts such as bolts, nuts, washers, and the time and labor required for installation.

Bolts may loosen under vibration conditions, and anti-loosening measures need to be taken, such as using anti-loosening washers and lock nuts.

(4) Examples

The connections between steel beams and steel columns in building steel structures, as well as the frame structure connections of mechanical equipment, are often connected by bolts to facilitate installation and disassembly.

Card connection

(1) Connection method

A method of achieving quick connection by using slots, buckles and other structures on sheet metal parts to cooperate with each other.

(2) Process advantages

The assembly speed is fast and no additional tools or connectors are required, which can greatly improve production efficiency, such as the assembly of electronic product shells and the rapid assembly of furniture.

The snap-on structure has certain elasticity and buffering properties, which can absorb vibration and impact and protect internal parts from damage.

It is relatively easy to disassemble and can be reused, which is conducive to the recycling and reuse of products and meets environmental protection requirements.

(3) Process shortcomings

The connection strength of the clip-on connection is limited and is not suitable for situations where large loads are applied. It is generally used for connections in light loads or non-critical areas.

The processing accuracy of sheet metal parts is high, and the size and shape of the clamping parts must be precisely matched, otherwise the clamping may be loose or impossible to assemble.

After long-term use, the snap-on structure may experience fatigue deformation, affecting the reliability of the connection.

(4) Examples

The casings of electronic products such as mobile phones and tablet computers are often assembled using a snap-on structure, which is quick and convenient, and also makes it easy to repair and replace parts.

Mortise and tenon connection

(1) Connection method

A method of connecting a part by machining a tenon on one sheet metal part and a corresponding mortise on another sheet metal part, and then inserting the tenon into the mortise.

(2) Process advantages

The connection is firm, and the mortise and tenon structure utilizes the mutual engagement and cooperation between parts to provide higher connection strength and stability, and is suitable for some sheet metal products with higher structural strength requirements.

With good decorative properties, the mortise and tenon connection can make the appearance of sheet metal parts more beautiful and refined, and is often used in the production of some high-end furniture and handicrafts.

No additional connectors are required, which reduces material costs and environmental pollution.

(3) Process shortcomings

The processing is difficult, requires precise processing technology and a high level of technology, has low production efficiency, and is not suitable for large-scale production.

There are certain requirements for the material and thickness of sheet metal parts. Thinner or softer sheet metal parts may not be suitable for mortise and tenon connections.

The structure of the mortise and tenon connection is relatively complex and difficult to disassemble, which is not conducive to subsequent maintenance and replacement.

(4) Examples

The frame structure of some high-end metal furniture adopts mortise and tenon connection, which not only ensures the stability of the structure but also has a unique decorative effect.

Gluing

(1) Connection method

A method of joining sheet metal parts together using adhesives.

(2) Process advantages

The stress is evenly distributed without causing stress concentration, making it suitable for connecting sheet metal parts of different materials, such as metal and plastic, metal and rubber, etc.

It has good sealing performance and can effectively prevent the leakage of liquid and gas. It also has certain insulation performance and can be used for sealing and insulating connections of electronic equipment.

The appearance is smooth and there are no exposed connectors, which can improve the aesthetics of the product and is suitable for sheet metal products with high requirements on appearance.

(3) Process shortcomings

The connection strength is greatly affected by environmental factors such as temperature, humidity, chemical media, etc., which may cause the performance of the adhesive to deteriorate and the connection strength to decrease.

The curing time is long, and it takes a certain amount of time for the adhesive to fully cure, which affects production efficiency, especially for large-scale production products.

The selection and use of adhesives requires certain professional knowledge and skills. Improper use may lead to connection failure or unstable quality.

(4) Examples

The casings and display frames of some electronic devices are connected using a gluing process, which not only ensures sealing performance but also has a good appearance.