Introduction

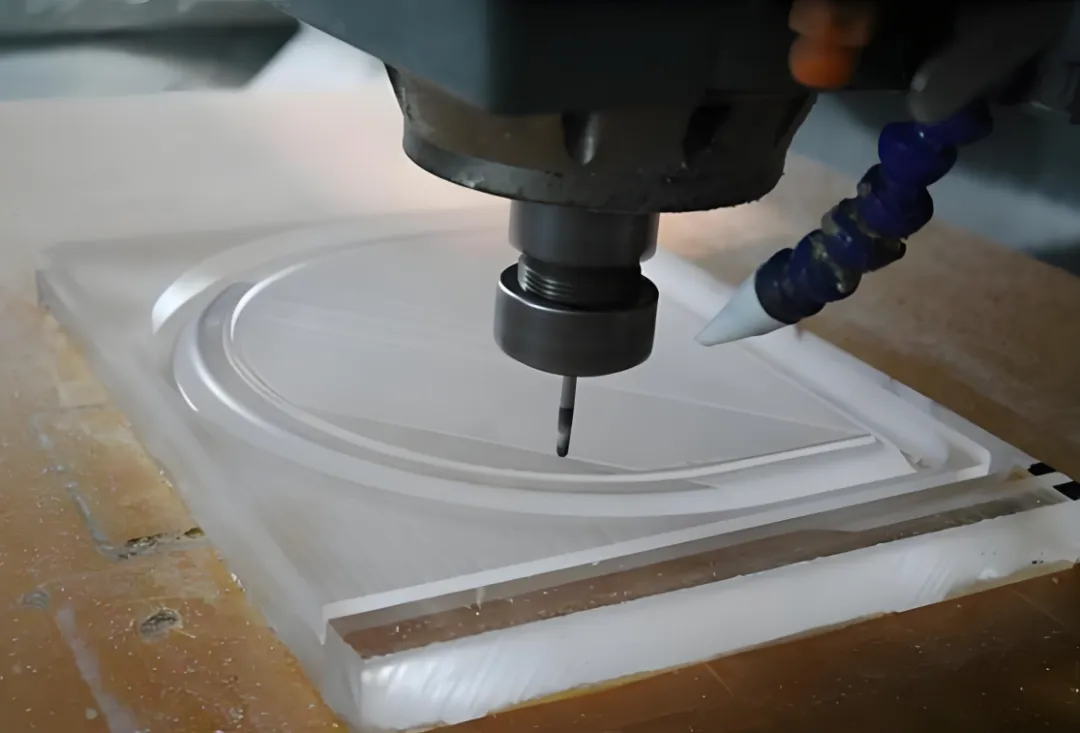

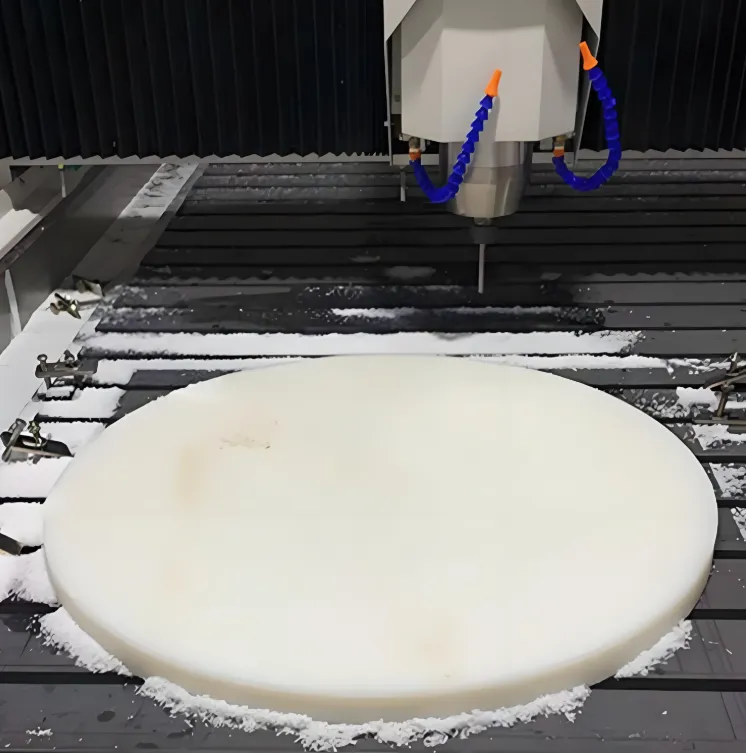

In the tide of modern manufacturing, plastics, with their unique properties, are thriving in numerous fields. CNC machining technology has further unlocked limitless possibilities for plastic materials, enabling them to meet diverse and complex demands with high precision and efficiency. ABS, PC, and PEEK—three high-performance plastics—each possess unique characteristics in CNC machining. A comparison of these three will unveil the mysteries of plastics processing.

Comparison of material properties and processing suitability

1, ABS (Acrylonitrile-Butadiene-Styrene Copolymer, a balanced choice)

ABS (Acrylonitrile-Butadiene-Styrene Copolymer) is a common thermoplastic plastic. It is like an “all-round player” in the plastic kingdom, achieving a relatively balanced state in many aspects such as mechanical properties and processing performance.

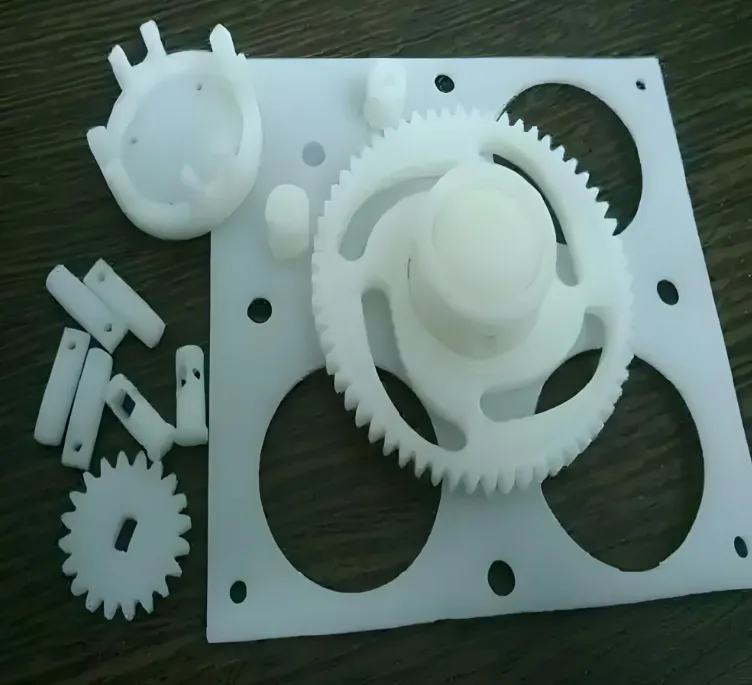

(1) Mechanical properties: ABS has good comprehensive mechanical properties. It has both certain strength and hardness, as well as good toughness and impact resistance. This allows ABS products to effectively resist damage when subjected to external impact, making them suitable for applications that require certain impact resistance, such as automotive interiors and home appliance housings. During CNC machining, this good toughness also helps reduce the risk of brittle fracture during processing.

(2) Processing performance: ABS has relatively good thermal stability and fluidity. In CNC processing, it can maintain stable processing performance over a wide temperature range. In various processing processes such as milling, turning, and drilling, ABS material is not prone to dimensional deviation and processing deformation caused by temperature changes. In addition, the surface finish of ABS after processing is relatively high. After appropriate post-processing, such as grinding and polishing, it is easy to obtain a smooth and beautiful surface, meeting the requirements of product appearance.

(3) Processing adaptability: ABS has excellent cutting performance, low heat generation during processing, and low tool wear, making it suitable for high-speed milling. Care should be taken in selecting coolant to avoid dissolution or deformation of the material surface.

(4) Application areas: Based on the above characteristics, ABS is widely used in many industries. In the automotive field, it is used to manufacture interior components such as instrument panels and door panels, which not only meet the aesthetic requirements but also can withstand certain external impacts. In the electronic and electrical industry, ABS is an ideal material for manufacturing housings, brackets, etc., providing good protection for electronic components while ensuring the appearance quality of the product.

PC (polycarbonate, a representative of transparency and toughness)

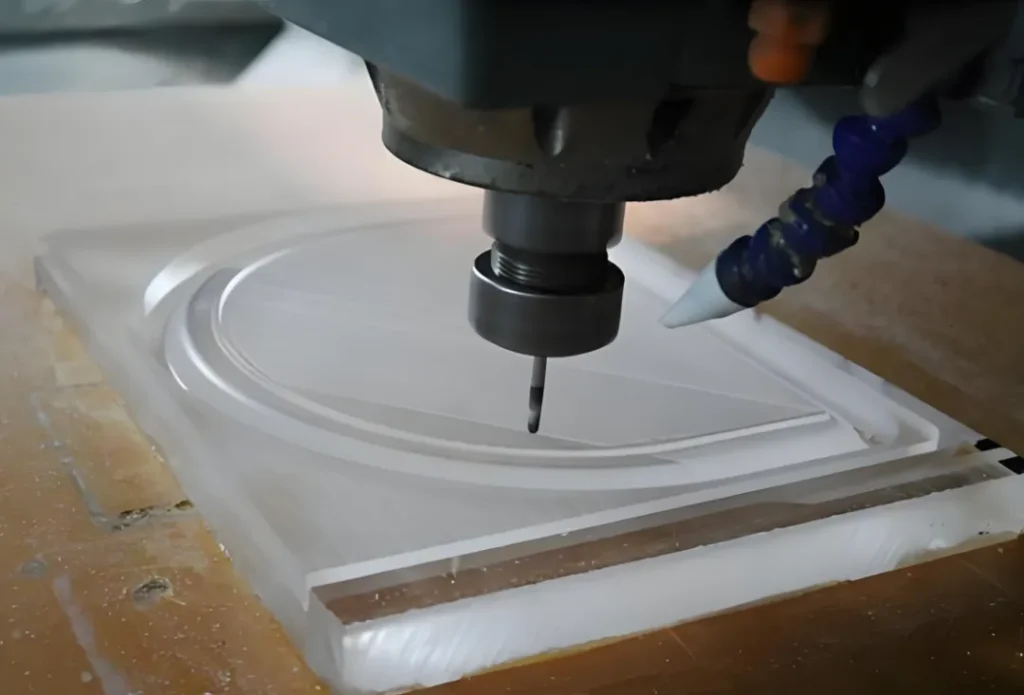

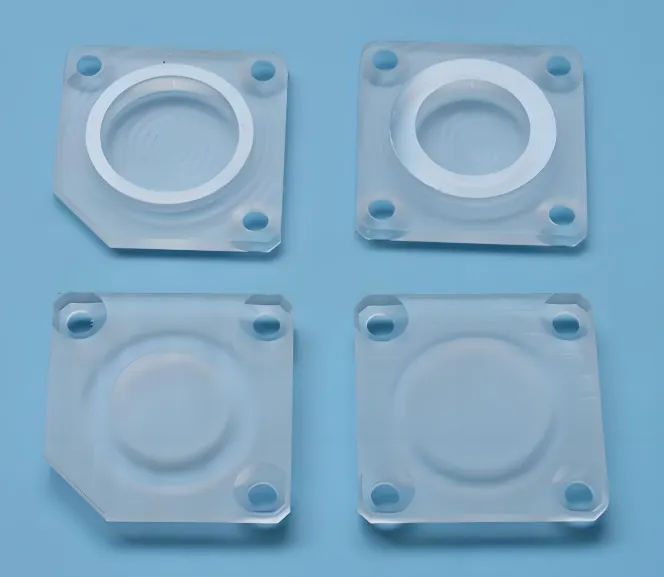

PC (polycarbonate) is unique in the plastic family for its unique transparency and excellent impact resistance. It is like a piece of strong and crystal “glass” and is highly favored in situations where transparency and high strength are required.

(1) Mechanical properties: PC has excellent impact resistance and can maintain good toughness even at extremely low temperatures, and will not break easily. This gives it a unique advantage in the manufacture of safety protection products such as protective masks and riot shields. However, PC has a relatively low hardness and is prone to scratches when subjected to high pressure or friction. This, to a certain extent, limits its use in some applications that require extremely high surface wear resistance.

(2) Processing performance: PC has a high thermal deformation temperature and can withstand a certain processing temperature during CNC processing. However, in actual processing, due to its high viscosity and relatively poor fluidity, precise control of processing parameters such as cutting speed and feed rate is required to avoid thermal degradation of the material due to excessive heat or difficulty in processing and forming due to insufficient fluidity. At the same time, the surface of PC after processing is prone to stress whitening, which requires corresponding measures to be taken in the processing technology and post-processing to improve, such as by optimizing the tool path, adjusting the cutting parameters, and performing appropriate heat treatment.

(3) Processing adaptability: PC has a high hardness, so sharp tools and controlled cutting speed are required to avoid overheating of the material, which may cause yellowing or cracking. Compressed air cooling is recommended rather than water-based coolant.

(4) Application areas: In addition to the field of safety protection, PC is also widely used in the field of electronics and electrical appliances. For example, it is made into transparent electrical appliance covers, which not only meets the need for transparent observation of internal structures, but also provides certain mechanical protection. In the field of optics, PC is used to manufacture lenses, optical discs and other products. Its good transparency and optical properties ensure the use effect of the products.

PEEK (polyetheretherketone, a leader in high performance)

PEEK (polyetheretherketone) is considered the “aristocrat” among plastics. It occupies a place in high-end manufacturing with a series of excellent properties and is an ideal choice for those who pursue high performance and high reliability.

(1) Mechanical properties: PEEK has extremely high strength and rigidity, and can maintain stable mechanical properties in harsh environments such as high temperature and high pressure. Its excellent fatigue resistance enables it to withstand repeated mechanical loads and is not prone to fatigue failure. This makes PEEK shine in fields such as aerospace and medical devices that require extremely high material performance, such as manufacturing aircraft engine parts and joints for medical devices, providing a strong guarantee for product safety and reliability.

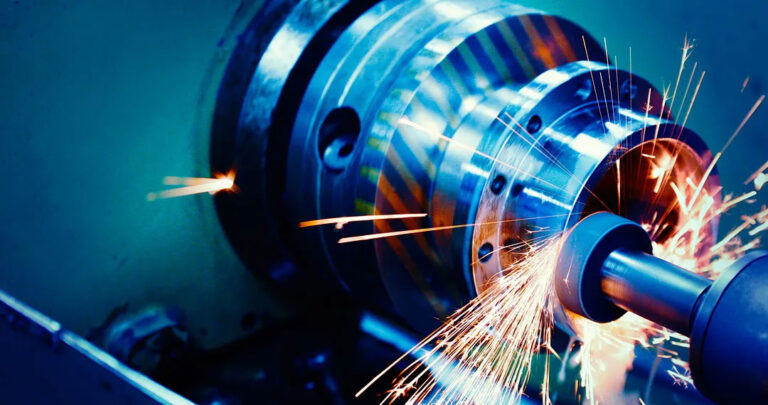

(2) Processing performance: PEEK has a high melting point and high crystallinity, which makes it extremely demanding on equipment and process requirements during CNC processing. High-precision, high-power processing equipment is required, and the processing temperature and tool parameters must be precisely controlled. During the processing, due to its high hardness and good wear resistance, the tool wear is relatively large, which requires regular inspection and replacement of the tool. At the same time, the difficulty of processing PEEK also leads to its relatively low processing efficiency and high cost. However, by adopting advanced processing technology and optimized process parameters, such as using sharp tools and appropriate cutting fluids, the processing quality of PEEK can be effectively improved.

(3) Processing suitability: PEEK has a high melting point (343°C), so high-hardness tools (such as diamond coatings) must be used and cutting parameters must be strictly controlled. A low-speed, high-feed strategy is recommended, combined with ultrasonic-assisted machining technology to reduce burrs and tool wear.

(4) Application areas: In the aerospace field, parts made of PEEK can not only reduce the weight of aircraft, but also improve their corrosion resistance and fatigue resistance. In the field of medical devices, the biocompatibility and chemical corrosion resistance of PEEK materials enable them to be in long-term contact with human tissue, providing patients with safe and reliable medical solutions.

CNC machining parameter optimization suggestions

| parameter | ABS | PC | PEEK |

|---|---|---|---|

| cutting speed | 2000-3000 RPM | 1500-2500 RPM | 800-1200 RPM |

| Feed speed | 0.1-0.3 mm/tooth | 0.05-0.2 mm/tooth | 0.02-0.1 mm/tooth |

| Tool material | High-speed steel or carbide | Carbide or diamond coating | Diamond-coated or CBN tools |

| Cooling method | Water-based coolant or dry cutting | Compressed air or minimal lubrication | Supercritical CO₂ or ultrasound-assisted cooling7 |

| Surface treatment | Polishing or sandblasting | Chemical passivation to prevent stress cracking | Mirror polished or PTFE coated |

Note: Using ultrasonic vibration technology when processing PEEK can increase tool life by 67% and achieve precision micro-hole processing with an aperture error of less than 0.01mm.

Comparative analysis of three types of plastics

1, Material cost: ABS has a relatively low cost and is suitable for large-scale, low-cost production needs; PC has a moderate cost, a relatively balanced performance and price, and can meet applications with certain requirements for transparency and impact resistance; PEEK has a high cost and is mainly used in high-end manufacturing fields with extremely high performance requirements and regardless of cost.

2, Processing difficulty and efficiency: ABS is easy to process, has high processing efficiency, and is easy to process complex shapes; PC is moderately difficult to process, and requires certain experience and skills to control processing quality and efficiency; PEEK is difficult to process, has extremely high requirements for equipment and processes, and has relatively low processing efficiency.

3, Chemical corrosion resistance: ABS has average chemical corrosion resistance and can withstand some common weak acids and weak bases, but its performance will deteriorate in harsh chemical environments such as strong acids and strong bases; PC also has good chemical corrosion resistance, but may swell or dissolve in certain specific chemical solvents; PEEK has excellent chemical corrosion resistance and is almost unaffected by most chemicals, including strong acids and strong bases.

Industry Application Scenarios and Cost-Benefit Analysis

1, Medical device field

(1) ABS: used for low-cost surgical tool prototypes, with a single piece processing cost of approximately 20-50 yuan.

(2) PC: Suitable for transparent guide parts, but requires additional antibacterial coating, which increases the cost by about 30%.

(3) PEEK: The first choice for orthopedic implants. Although the material cost is more than 10 times that of ABS, its biocompatibility can reduce the risk of postoperative complications.

2, Automobile manufacturing

(1) ABS: widely used in instrument panels and interior parts, with a small batch processing cycle of only 1-3 days .

(2) PC: Car headlight covers and sunroof components rely on its light transmittance, but need to avoid yellowing caused by long-term ultraviolet radiation .

(3) PEEK: High temperature resistant parts such as turbocharger sealing rings can replace metal and reduce weight by 40%, but mass production needs to be combined with injection molding process to reduce costs.

3, Electronic semiconductor field

(1) ABS: Suitable for insulating brackets with simple structures, the cost-effectiveness is 60% higher than that of metal.

(2) PC: Used for high-transmittance connectors, but the processing temperature needs to be controlled to prevent internal stress accumulation.

(3) PEEK: used to manufacture microcircuit board test pieces, capable of stably processing 5,000 microholes with a diameter of 0.175 mm, with a yield rate of 99%.

Common Problems and Solutions

1, The surface of ABS is rough after processing.

(1) Cause: The tool is blunt or the feed speed is too fast.

(2) Solution: Replace the sharp tool, reduce the feed to 0.1 mm/tooth, and use sandblasting post-processing.

2, Cracks appear during PC processing

(1) Cause: Improper stress release or cooling of the material.

(2) Solution: Anneal the sheet before processing and use compressed air cooling instead of water-based liquid.

3, PEEK tool wear is too fast

(1) Cause: The cutting temperature is too high, causing the material to stick to the knife.

(2) Solution: Use ultrasonic assisted machining system to reduce cutting resistance and improve cooling efficiency.

Conclusion

In summary, ABS, PC, and PEEK—three high-performance plastics—each have their own unique characteristics in CNC machining. In practical applications, the appropriate plastic material must be selected based on a variety of factors, including product performance requirements, cost budget, and production scale.

Only by deeply understanding the characteristics of each material and combining them with advanced CNC machining techniques can we fully leverage their advantages, providing high-quality, high-performance plastic products for various industries, meeting growing market demand, promoting the sustainable development of the manufacturing industry, and creating a more exciting chapter in the vast arena of plastics processing.