Introduction

With the advancement of technology, CNC machining has placed higher demands on part complexity, precision, and craftsmanship, making traditional manual programming inadequate. Consequently, CAM (Computer-Aided Manufacturing) software has emerged. This software utilizes computers to manage, control, and operate production equipment. Its input information is the part’s process routing and process details, and its output information is the tool’s motion trajectory (tool path file) and the CNC program.

Mastercam

Mastercam is a PC-based CAD/CAM software developed by American company CNC Software Inc. It integrates multiple functions such as 2D drawing, 3D solid modeling, surface design, voxel stitching, CNC programming, tool path simulation, and realistic simulation.

Mastercam offers powerful surface roughing and finishing capabilities, with multiple surface finishing options to meet the surface machining requirements of complex parts. It also features multi-axis machining capabilities. Due to its low price and superior performance, it has become the preferred CNC programming software for the domestic civilian industry.

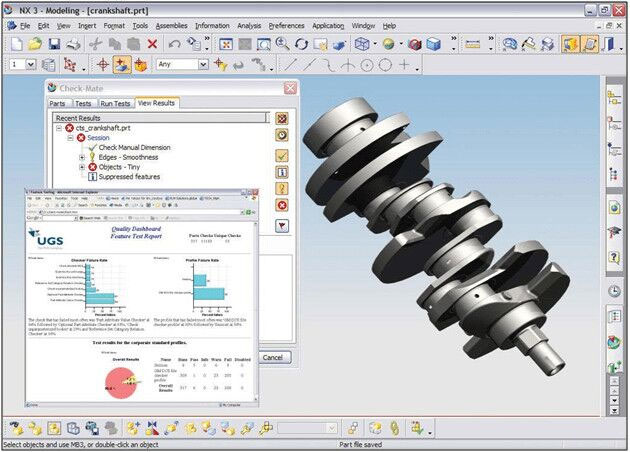

UG Unigraphics

UG Unigraphics is a 3D parametric software suite developed by Unigraphics Solutions, Inc. in the United States. It integrates CAD, CAM, and CAE functions. It is currently the most advanced high-end computer-aided design, analysis, and manufacturing software, used in industries such as aviation, aerospace, automotive, shipbuilding, general machinery, and electronics.

It offers the following advantages:

- Provide reliable and accurate tool paths

- Can process directly on curved surfaces and solid bodies

- Good user interface, customers can also design their own interface

- Various processing methods facilitate the design and combination of efficient tool paths

- Complete tool library

- Processing parameter library management function

- Includes two-axis to five-axis milling, lathe milling, wire cutting

- Large tool library management

- Solid simulation cutting

- General purpose post-processor and other functions

- With high-speed milling function

Pro/E

Pro/E, developed by PTC (Parametric Technology Corporation) in the United States, is the world’s most popular 3D CAD/CAM (Computer-Aided Design and Manufacturing) system. It is widely used in consumer industries such as electronics, machinery, molds, industrial design, and toys. It offers a wide range of functions, including parts design, product assembly, mold development, CNC machining, and styling design.

Pro/E is widely used in enterprises in southern my country. It is currently common practice to use PRO-E for design and modeling, and MASTERCAM and CIMATRON for programming and processing.

Cimatron CAD/CAM system

Cimatron’s CAD/CAM/PDM products are among the first to implement full-featured 3D CAD/CAM systems on a microcomputer platform. They offer a flexible user interface, superior 3D modeling and engineering drawing, comprehensive CNC machining, a variety of general and specialized data interfaces, and integrated product data management. Cimatron’s CAD/CAM systems are highly sought after in the mold and die manufacturing industry internationally and are also widely used within the domestic mold and die manufacturing industry.

FeatureCAM

Developed by the American company DELCAM, this full-featured, feature-based CAM software features a brand-new concept, powerful feature recognition, a material library based on a process knowledge base, a tool library, and a process card-based programming model with icon navigation. This fully modular software offers comprehensive solutions for shop floor programming, from 2- to 5-axis milling to mill-turn machining, from surface machining to wire EDM. DELCAM’s post-editing capabilities are relatively advanced.

In recent years, some domestic manufacturing companies are gradually introducing it to meet the needs of industry development. It is an emerging product.

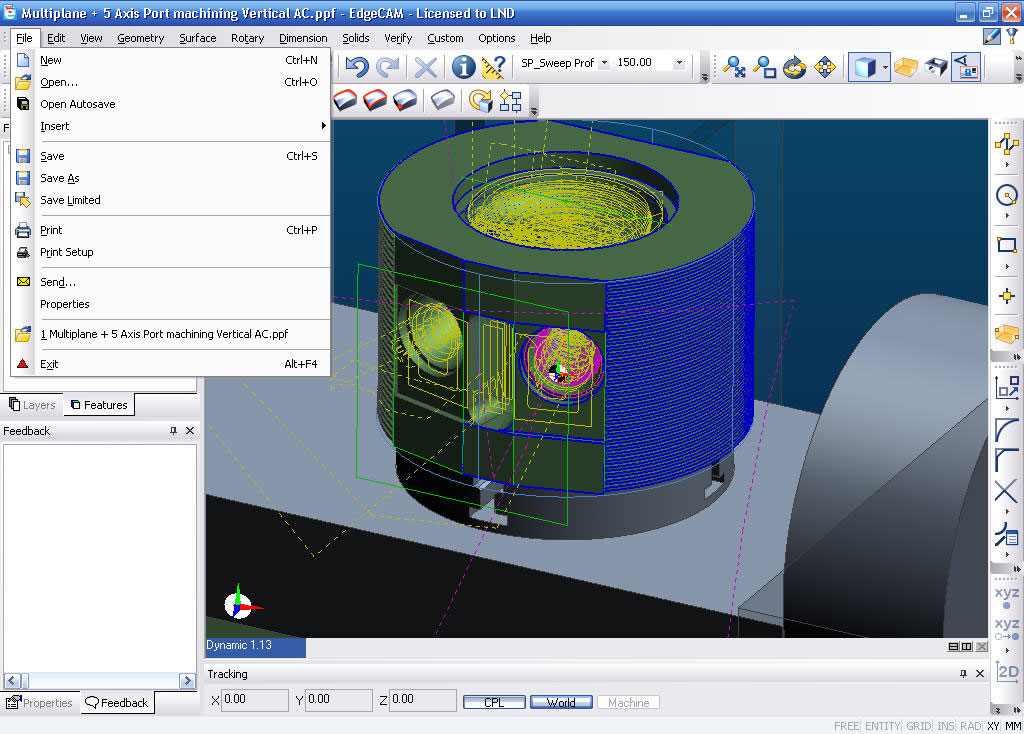

EdgeCAM

Pathtrace, a British company, offers intelligent, professional CNC programming software for CNC machine tools such as turning, milling, and wire cutting. EdgeCAM, designed to address the complexities of 3D surface machining, offers more convenient and reliable processing methods, making it popular in the European and American manufacturing industries. Pathtrace is currently developing and operating in the Chinese market, offering more options for domestic manufacturing clients.

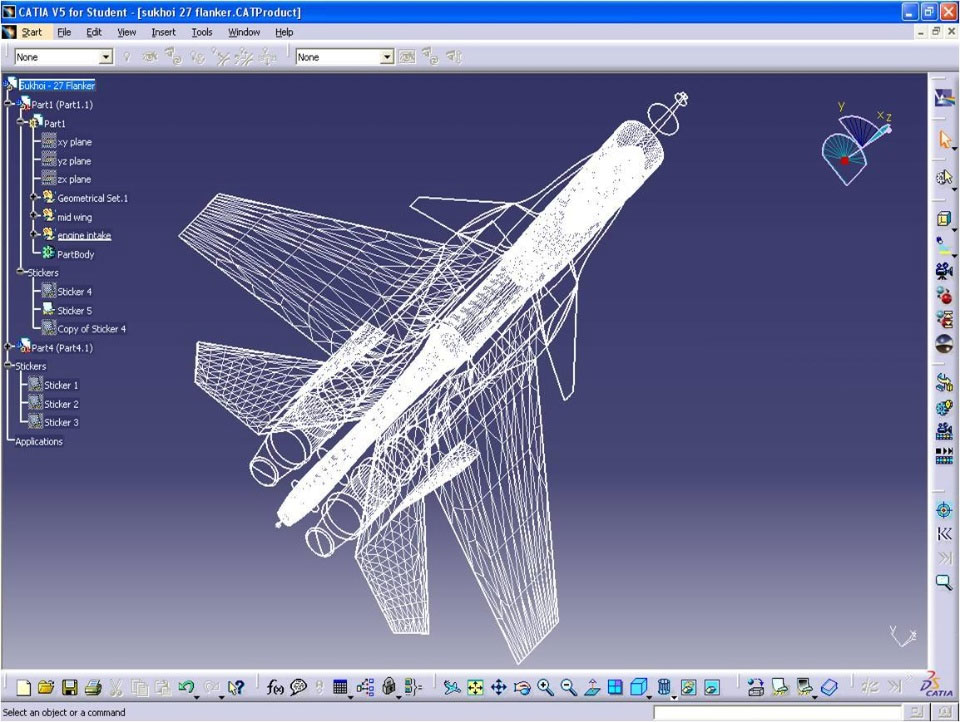

Catia

Catia is a product launched by the French company Dassault. Catia was used in the development and design of the French Mirage series fighter jets, Boeing 737 and 777.

CATIA has powerful surface modeling capabilities and ranks among the top CAD 3D software. It is widely used in domestic aerospace companies and research institutes, and is gradually replacing UG to become the first choice for complex surface design.

CATIA has strong programming capabilities and can meet the requirements of CNC machining of complex parts. Currently, some fields use CATIA design and modeling, and UG programming and machining, combining the two.

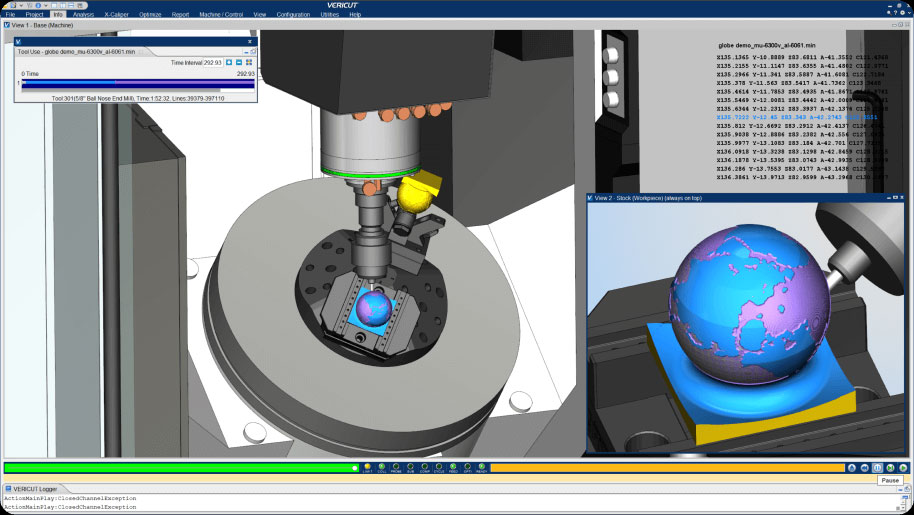

VERICUT

VERICUT, a specialized, advanced CNC machining simulation software developed by CGTECH in the United States, utilizes advanced 3D display and virtual reality technologies to achieve an exceptionally realistic simulation of the CNC machining process. It not only displays the entire process of a tool cutting through a blank to form a part using color 3D images, but also displays toolholders, fixtures, and even simulates the machine’s operation and the virtual factory environment. The effect is like watching a video of a CNC machine machining a part on a screen.

Programmers import NC machining programs generated by various programming software into VERICUT, which verifies them. This software can detect calculation errors in the original software programming and reduce the rate of machining accidents caused by program errors. Currently, many leading domestic companies have begun to introduce this software to enhance their existing NC programming systems, with good results.

With the rapid development of manufacturing technology, the development and use of CNC programming software has also entered a new stage of rapid development. New products are emerging in an endless stream, and functional modules are becoming more and more refined. Process personnel can easily design scientific, reasonable and personalized CNC machining processes on microcomputers, making CNC machining programming easier and more convenient.

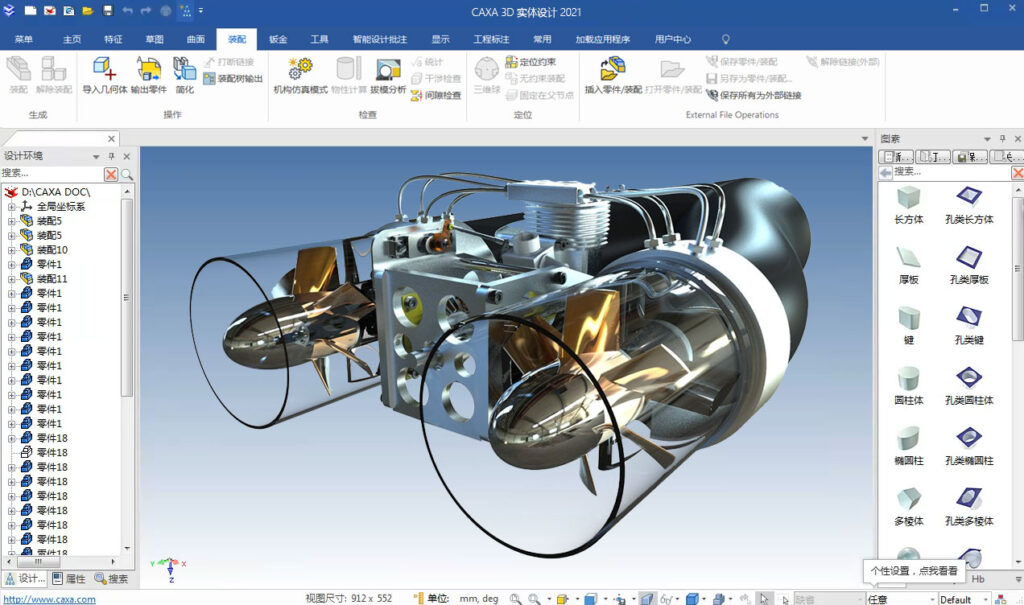

CAXA

CAXA Manufacturing Engineer is a CAM product launched by Beijing Beihang Haier Software Co., Ltd., establishing a significant presence for domestic CAM software in the CAM market. As a leading brand and representative of proprietary software in China’s manufacturing information technology sector, CAXA has become a leading supplier and major supplier in China’s CAD/CAM/PLM industry.

CAXA Manufacturing Engineer is a milling/drilling CNC machining programming software designed for two- to five-axis CNC milling machines and machining centers, offering superior process performance. Its superior performance and affordable price have made it very popular in the domestic market.